Your container has arrived, but the high-security bolt seal won't budge. Your crew is wasting valuable time trying pliers and hacksaws, but nothing is working, and the risk of injury is growing.

To cut a high-security, ISO 17712 "H" compliant bolt seal, you need a large, high-quality pair of bolt cutters. Any attempt to use shortcuts like hammers or saws will not only fail but is also extremely dangerous.

In my 20+ years of experience, there's only one right answer to the question "what tool do you need to cut a high-security bolt seal?" The answer is a large, high-quality pair of bolt cutters. As manufacturers, we put a significant amount of material science and engineering into this small seal to ensure it resists everything except this one authorized tool. So, the next time your staff complains that a seal is too hard to cut, you should be happy. It's the clearest possible proof that you bought a genuine high-security product that is doing its job perfectly.

Why Are Bolt Cutters the Only Choice for High-Security Bolt Seals?

You see a hardened steel pin and think any steel-cutting tool will work. Frustration builds as a brand-new hacksaw blade dulls after barely scratching the surface of the bolt seal.

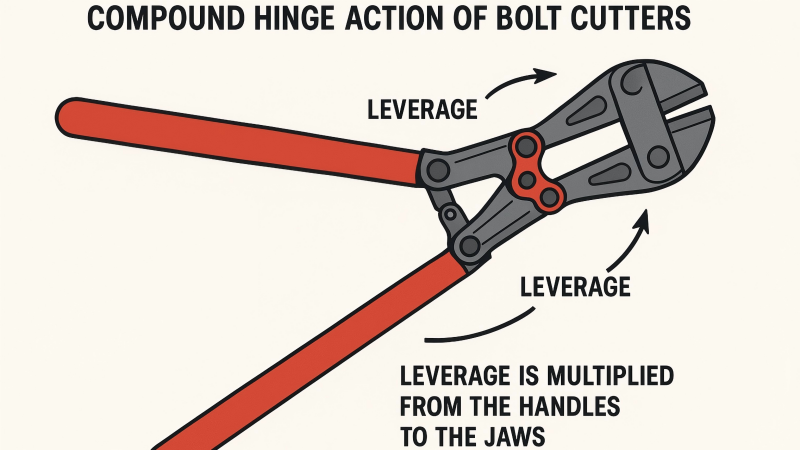

Bolt cutters are the only effective tool because they attack the seal with overwhelming mechanical force, not friction. Their compound hinges multiply your arm strength, allowing hardened blades to deliver a focused point of pressure that snaps the steel pin.

A high-security bolt seal is specifically engineered to resist casual or opportunistic tampering. This engineering is focused on defeating tools that rely on abrasion or simple leverage. Bolt cutters overcome this through a combination of three key principles:

- Leverage: Long handles provide a significant mechanical advantage, turning a small amount of force on your part into a much larger force at the jaws.

- Compound Action: The dual-pivot design multiplies this force even further. A force of 50 pounds on the handles can translate to nearly 4,000 pounds of cutting force at the blades.

- Hardened Blades: The blades of a quality bolt cutter are made of forged, hardened steel, specifically designed to be harder than the steel pin of the seal. This ensures the blade cuts the pin, not the other way around.

This is why other tools fail: they lack the necessary combination of all three of these principles.

How Do You Select the Right Bolt Cutter Size to Defeat a Seal?

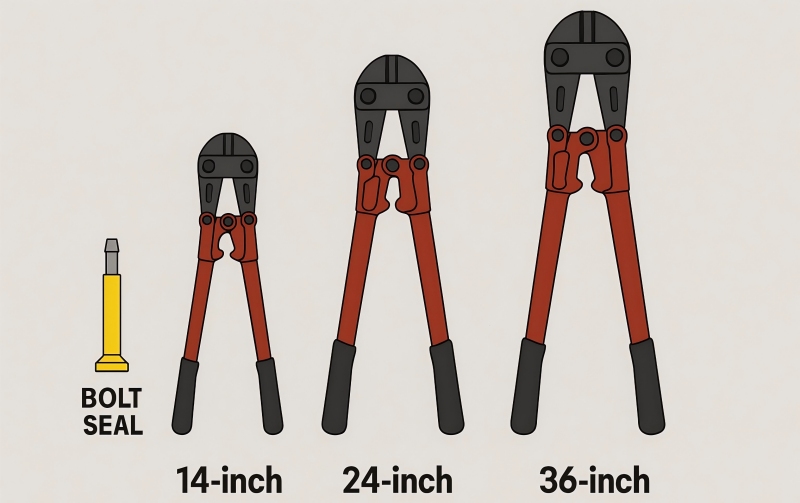

You bought a small, 14-inch pair of bolt cutters to save money. Now you're using your entire body weight on the handles, and the bolt seal's pin is barely dented.

The size of the bolt cutter directly determines its cutting capacity and the leverage you can apply. For standard high-security bolt seals, a 24-inch (600mm) cutter is the minimum professional standard, while a 36-inch (900mm) model provides maximum safety and efficiency.

Longer handles equal greater leverage, which means less physical effort and a safer cut. Choosing a tool that is too small is not only ineffective but also increases the risk of the tool slipping or the user straining themselves. I've been on-site at logistics yards and have seen this firsthand. Here is a simple guide for choosing the right size:

| Bolt Cutter Size | Typical Use Case | Effectiveness on Bolt Seals |

|---|---|---|

| 12-18 inches (300-450mm) | Fencing, small chains, thinner bolts. | Ineffective & Dangerous. Lacks the leverage to cut a hardened steel pin. High risk of tool failure or injury. |

| 24 inches (600mm) | Rebar, medium bolts. | Minimum Professional Standard. Can cut most bolt seals, but may require significant user strength. |

| 36-42 inches (900-1050mm) | Thick steel rods, industrial use. | Highly Recommended. Provides the best leverage, making the cut cleaner, faster, and significantly safer for the operator. |

Investing in a 36-inch cutter is a smart decision for any operation that removes bolt seals regularly. The reduction in effort and increase in safety is well worth the cost.

What Is the Correct Technique for Cutting a Bolt Seal Safely?

You're ready to cut the seal, but you're worried about the cut end flying off and causing an injury. An uncontrolled release of metal under high tension is a serious safety hazard.

The correct technique involves more than just brute force. It requires wearing proper Personal Protective Equipment (PPE), ensuring a stable stance, and applying steady, controlled pressure to the bolt cutter handles.

Safety should always be the top priority. A bolt seal's pin can fracture unpredictably when cut. Follow these steps every time:

1. Wear Your PPE

This is non-negotiable. At a minimum, you need ANSI-rated safety glasses or a full face shield. Heavy-duty work gloves will protect your hands.

2. Get a Stable Stance

Plant your feet firmly on the ground, shoulder-width apart. Ensure your footing is not slippery. Never try to cut a seal while off-balance or perched on a ladder.

3. Position the Cutter Correctly

Open the jaws and place them as deep as possible onto the steel pin of the bolt seal. Cutting with the tips of the blades is inefficient and can damage the tool.

4. Apply a Smooth, Squeezing Motion

Bring the handles together with a steady, controlled force. Do not jerk or twist the tool. Let the cutter's leverage do the work. The goal is a clean snap. Be prepared for a sudden release of tension as the pin breaks.

Why Do Hammers and Hacksaws Always Fail?

In a moment of frustration, your employee grabs a sledgehammer, hoping to smash the seal open. The hammer blow glances off the spinning plastic cover, achieving nothing but creating a dangerous risk of ricochet.

Hammers and hacksaws fail because a bolt seal is specifically designed to defeat them. The hardened steel core resists a hacksaw's abrasion, and the freely spinning anti-tamper jacket dissipates the force of a hammer blow.

Let's break down the science behind why these common tools are useless against a well-made seal.

- Hacksaws Fail Due to Hardness: A hacksaw cuts by having teeth that are harder than the material being cut. High-security bolt seals use case-hardened steel pins with a Rockwell hardness (HRC) of over 45-50. A standard hacksaw blade is simply not hard enough to bite into it; the seal will wear down the blade instead.

- Hammers Fail Due to Design: The plastic or metal jacket over the locking mechanism isn't just for show. It's designed to spin freely. When you strike it with a hammer, the jacket rotates, deflecting the impact energy rather than transferring it to the internal lock. This anti-spin feature is a key element of a seal's security.

Does the Bolt Cutter's Blade Material Really Matter?

You bought a cheap, unbranded pair of bolt cutters. On the third seal, one of the blades chips, rendering the expensive tool useless and creating a flying metal hazard.

Yes, the blade material is critically important. Quality bolt cutters use forged alloy steels (like chrome-vanadium) that are heat-treated to be significantly harder than the seal's pin. A cheap cutter uses softer steel that will chip, deform, or fail.

When you buy a bolt cutter, you are paying for the quality of the steel in the blades. Look for these terms:

- Forged Steel: Forging aligns the grain of the steel, making it much stronger and more durable than cheaper cast metal.

- Hardened or Heat-Treated: This process changes the molecular structure of the steel to maximize hardness and wear resistance.

- Alloy Steel (e.g., Cr-V, Cr-Mo): Adding elements like Chromium, Vanadium, or Molybdenum creates a blade that is not only hard but also tough, meaning it can withstand the shock of cutting without fracturing.

A quality blade will be rated to cut materials up to a certain hardness (HRC). Investing in a reputable brand of bolt cutters is an investment in safety and long-term reliability.

Conclusion

The only correct tool to cut a high-security bolt seal is a large, well-made bolt cutter. The difficulty you experience when trying other tools isn't a product flaw; it's the very security you invested in.

Get Security You Can Rely On with ProtegoSeal

Our high-security bolt seals are engineered to be tough because your cargo's security is our top priority. The resistance they offer is proof of their quality. At ProtegoSeal, we provide security solutions that work. Contact us to ensure your assets are protected by a seal that does its job.