You bought a batch of "high-security" seals and assumed your cargo was safe. But a container is rejected, or worse, compromised, because the seal wasn't what it claimed to be.

A bolt seal earns the "high-security" and ISO 17712 certified titles by passing a dual assessment. It must first survive brutal physical strength tests and then meet stringent security-related manufacturer practices, ensuring it's a reliable forensic tool against both brute force and intelligent tampering.

For years, I've seen clients focus solely on the physical strength of a bolt seal. They'll ask, "How hard is it to cut?" While that's important, it's only the first line of defense. The "High-Security" classification under ISO 17712 is a two-dimensional assessment. It evaluates a seal's ability to resist not just "brute-force attacks" but also, more critically, "intelligent attacks" and process loopholes. I believe the second line of defense—the manufacturer's security practices and the seal's tamper-evident design—is what truly defines its security credentials. Let's break down both dimensions.

ISO 17712 Explained: The Gold Standard for Global Freight Security

You hear terms like "ISO compliant" and "certified," but what do they actually mean? Without a clear definition, these are just marketing buzzwords.

ISO 17712 is the international standard that establishes uniform procedures for the classification, acceptance, and withdrawal of mechanical freight container seals. It creates a "common language" for security that is recognized globally.

I explain ISO 17712 to my clients as the official rulebook for freight security. It ensures that a seal from any certified manufacturer in the world provides a consistent, verifiable level of security. It's published by the International Organization for Standardization, an independent body, which gives it authority. The standard categorizes seals into three classes, creating a clear hierarchy of security.

The Three Classes of ISO 17712:

| Class | Seal Type | Primary Function | Example |

|---|---|---|---|

| I | Indicative | Provides evidence of tampering. Low physical strength. | Simple Plastic Seals |

| S | Security | Provides a limited barrier to entry and tamper evidence. | Cable Seals |

| H | High-Security | Provides the highest barrier security; must be removed with heavy-duty tools. | Bolt Seals |

For a bolt seal to function as a tool of accountability in international trade, it must meet the "H" classification.

The Gauntlet of Tests: What Physical Forces Must a Bolt Seal Withstand?

You want proof a seal can survive a real-world attack, not just a promise. What does a seal actually endure to prove its strength?

To earn an "H" rating, a bolt seal is subjected to a series of brutal laboratory tests that simulate aggressive tampering attempts, measuring its resistance to being pulled, cut, and smashed.

This is the "brute-force" dimension I mentioned earlier. This is where the seal's material science and engineering are put to the test. A lab, accredited under ISO/IEC 17025, performs these tests to ensure unbiased results. The seal must meet or exceed specific force thresholds.

The ISO 17712 Physical Trials:

- Tensile Test: The locked seal is pulled apart by a machine. To pass, it must withstand more than 10.0 Kilonewtons (kN) of force—that's over 1,000 kg or 2,205 lbs. It ensures the lock doesn't fail under heavy stress.

- Shear Test: This test simulates an attack with cutters. A blade attempts to slice through the steel pin. The seal must prove it requires heavy-duty tools, confirming its status as a true physical barrier.

- Impact Test: The seal is frozen to -40°C and then heated to +55°C and struck with a 5 kg weight at each temperature. This proves the seal won't become brittle in the cold or soft in the heat, maintaining its integrity across global shipping climates.

Passing these tests is the first major hurdle to becoming a high-security seal.

Beyond the Test Lab: The Importance of the Certification Process and Manufacturer Security Practices

The seal passed its physical tests. Does that guarantee every seal you buy is secure? Not if the manufacturer has poor security protocols.

True security also requires certification of the manufacturer's processes. Annex A of ISO 17712 mandates audits of the supplier's security practices, covering everything from production controls to preventing theft of their own seals.

This second dimension is what separates a truly high-security provider from a company that just makes strong metal parts. This is the defense against "intelligent attacks." A bad actor could try to source blank seals, duplicate numbers, or learn about master keys if the manufacturer's security is weak. I've seen situations where a shipment was compromised with a perfect-looking seal that was sourced illegitimately from a factory with loose controls. This is why Annex A is so critical.

Key Areas Audited in Annex A:

- Access Control: Strong controls over who can access production areas and finished inventory.

- Employee Vetting: Performing background checks on key personnel.

- Production Controls: Strict procedures for numbering, preventing duplicates, and destroying defective parts.

- Data Security: Protecting the databases of serial numbers and customer orders.

A secure product from an insecure facility is an insecure product.

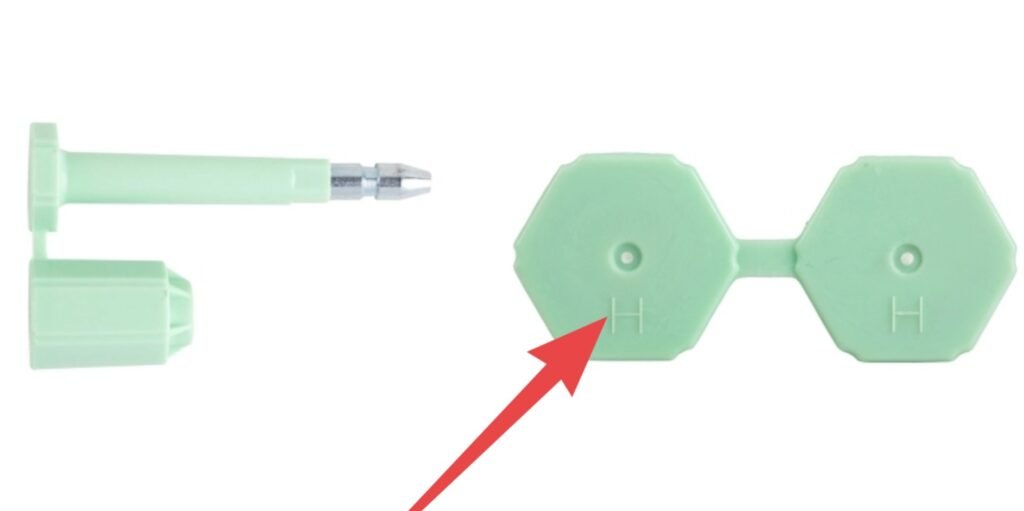

The Meaning of the "H": How to Quickly Identify a Genuine High-Security Seal

You're at a loading dock and need to verify a seal is a genuine high-security one. How can you tell at a glance?

Look for the "H" marking. All certified ISO 17712 high-security seals must be visibly and permanently marked with the letter "H" on the seal itself.

This simple letter is your fastest indicator of compliance. It’s part of a system of markings that provide essential information at a glance. When you're managing dozens of containers, you don't have time to look up certificates for every seal. You need to be able to trust what you see.

What to Look For on a High-Security Seal:

- The "H" Classification: The most important visual cue. If there is no "H", it is not a certified high-security seal, regardless of what the supplier claims.

- Manufacturer's Name or Logo: Identifies who produced the seal, tying it back to a specific certified company.

- Unique Serial Number: Must be present on both the pin and the locking body. This is the foundation of the seal's function as an audit trail device.

I always tell my team: "No 'H', no go." It's a simple rule that prevents major security lapses before a container even begins its journey.

Why Certification Matters: The Impact of ISO 17712 on C-TPAT and Global Trade

Why should you invest in certified seals? Will it actually make a difference to your business operations?

Using ISO 17712 certified seals is essential for participating in global trade security programs like C-TPAT. Non-compliance can lead to severe delays, increased inspections, and even denial of entry at borders.

This is where certification directly impacts the bottom line. These security initiatives, led by customs agencies around the world, are designed to secure the entire supply chain. They offer significant benefits to members, such as faster customs processing and fewer inspections. But to join, companies must demonstrate that they have robust security measures in place. Using compliant high-security seals is a non-negotiable requirement.

The Business Case for Certification:

- Reduced Friction: C-TPAT members are 4-6 times less likely to undergo a security-related customs examination. This means faster transit times and a more predictable supply chain.

- Risk Mitigation: In the event of a security incident, using a certified seal demonstrates due diligence and can help limit liability.

- Brand Trust: It signals to your partners and customers that you take security seriously, enhancing your reputation as a reliable operator in international trade.

Ultimately, the cost of a certified seal is a small price to pay for the access and security it provides.

Conclusion

A bolt seal's "high-security" status is earned, not claimed. It comes from a dual certification: passing brutal physical tests and proving the manufacturer has ironclad security processes, all verified under the ISO 17712 standard.

Insist on True Certification with ProtegoSeal

Don't settle for claims. Demand proof. At ProtegoSeal, our "H" rated bolt seals are fully ISO 17712 certified, meeting both physical and procedural security standards. Contact us to ensure your seals are truly secure.