Your container arrives, the doors are closed, but thousands of dollars of merchandise are missing. With no broken lock and no sign of forced entry, you have no proof of theft, leaving you to absorb the massive loss.

Sealing in logistics is the critical process of applying a uniquely numbered, tamper-evident device to a shipment. Its main purpose is to prevent undetected tampering and provide a verifiable record that the cargo has remained secure from its point of origin to its destination.

Over my career, I've seen many people misunderstand the role of a seal. They think of it as a lock, focusing only on its physical strength. This misses the entire point. The most important function of a seal in logistics is to take a "snapshot" of the cargo's "innocence." This snapshot is taken the moment the shipper locks the seal, and it remains valid until the moment the consignee inspects it. Any change to that seal means the snapshot has been broken, and the original state of the cargo may have been compromised. This guide will explain why that simple concept is one of the most powerful tools in your entire supply chain.

Defining Sealing: More Than Just a Physical Barrier?

You see a plastic tag on a truck door and think of it as a simple deterrent. This leads you to choose the cheapest option, underestimating its vital role as an information tool.

Sealing is the formal application of a single-use, uniquely identified device to create a secure record. It's not about preventing entry with brute force; it's about providing undeniable evidence if entry was attempted. It’s an information device, not a strength device.

Let's dive deeper into the "snapshot" metaphor. A photograph captures a single moment in time. A security seal does the same for the status of your cargo. This concept is built on two fundamental pillars:

1. Uniqueness

Every single seal has a unique serial number. This number is like the time and date stamp on your photograph. It is recorded on the shipping documents (like the Bill of Lading) and creates a one-to-one link between that specific seal and that specific shipment. There can be no disputes.

2. Irreversibility

A security seal is designed for a single use. Once it's locked, it cannot be opened without being destroyed. Once it's broken, it cannot be repaired or resealed. This irreversible act permanently "breaks the snapshot," providing clear evidence that the cargo's state has potentially changed.

| Feature | Conventional Padlock | Security Seal |

|---|---|---|

| Primary Function | Physical Security (Strength) | Information Security (Evidence) |

| Uniqueness | Key is duplicated | Serial number is unique |

| Reusability | Reusable | Single-use only |

| Purpose | To be opened and closed | To be applied once and broken once |

The Primary Purpose: Preventing Tampering and Theft?

You worry about thieves targeting your high-value cargo during transit. You envision them using brute force, but the real threat is often more subtle and harder to prove.

A seal acts as a primary deterrent to opportunistic theft and provides the crucial evidence needed for insurance claims. It transforms a potential "mysterious loss" into a documented tampering event at a specific point in the supply chain.

A seal's power isn't in stopping a determined criminal with heavy-duty tools; it's in preventing the easy, deniable theft that plagues the logistics industry.

Deterring Opportunistic Theft

Most cargo theft isn't a "heist movie" scenario. It's often a driver or warehouse worker opening a door for a few seconds to grab a couple of boxes. A simple seal makes this impossible to do without leaving evidence. The risk of being caught increases dramatically, and most thieves will simply move on to an easier, unsealed target.

Creating an Audit Trail

Imagine a container travels from your factory to a port, onto a ship, to another port, and finally to your customer. If goods are missing, where did the theft occur? Without a seal, it's your word against everyone else's. With a seal, the process is clear:

- You seal the container at your factory and record number

ABC12345. - The consignee inspects the container upon arrival.

- Scenario A: Seal

ABC12345is intact. Any shortage is likely a packing error. - Scenario B: The seal is missing, broken, or has a different number. You now have proof the container was opened after it left your control. The liability shifts to the carrier.

Key Benefits for Your Cargo and Business Operations?

You're focused on shipping costs and transit times. You haven't considered how a simple, inexpensive seal can have a direct, positive impact on your company's bottom line and reputation.

Implementing a sealing protocol offers significant benefits beyond security, including reduced insurance premiums, faster inspections, improved customer trust, and protection against liability claims.

The small investment in a robust sealing strategy pays for itself many times over. In my experience helping clients, these are the most impactful benefits they see:

- Reduced Financial Loss: This is the most obvious benefit. By deterring theft and providing evidence for claims, you directly protect your revenue and inventory from shrinkage.

- Lower Insurance Premiums: Many insurance companies recognize a documented sealing process as a key part of risk management. They may offer lower premiums to companies that can demonstrate they take cargo security seriously.

- Enhanced Customer Confidence: When your customer receives a shipment with the seal number they were given, it builds immense trust. It tells them you are a professional, detail-oriented partner who cares about their cargo.

- Protection Against Contamination & Fines: For industries like food and pharmaceuticals, an intact seal proves that the container was not opened and the contents were not contaminated. It also protects you if illegal substances were planted in your container after it left your facility.

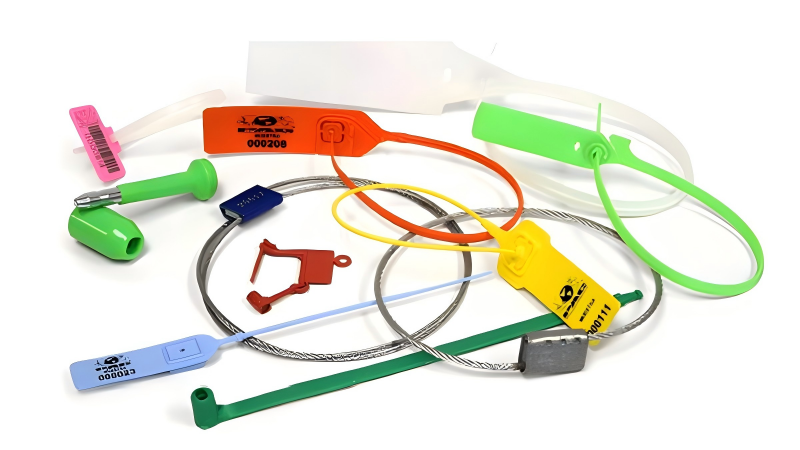

Common Types of Seals Used in Modern Logistics?

You know you need a seal, but the choices are overwhelming. Bolt seals, cable seals, plastic seals—how do you know which one provides the right level of security for your specific shipment?

The type of seal used depends on the value of the cargo and the risk of the shipping lane. Seals are generally categorized by their strength and security level, from simple plastic indicative seals to high-security bolt and cable seals.

Choosing the right seal is a matter of matching the tool to the job.

1. High-Security Seals (Bolt & Cable)

These are the workhorses for international shipping and high-value domestic cargo.

- Bolt Seals: Made of a steel pin and locking barrel, they are incredibly strong and require large bolt cutters to remove. They are the standard for cross-border shipping containers and must meet ISO 17712 standards.

- Cable Seals: A steel aircraft cable is looped through a locking body. They are more versatile than bolt seals and can be used on a wider variety of doors and valves.

2. Indicative Seals (Plastic & Wire)

These seals are not designed for high strength but to show evidence of tampering (to "indicate" entry).

- Plastic Pull-Tight Seals: These function like a zip tie with a unique number. They are perfect for truck trailers, tote boxes, and situations where a quick, visual check is needed.

- Meter Seals: A thin wire is twisted and crimped inside a plastic body. They are used for securing smaller items like utility meters, ATM cassettes, and airline carts.

How to Implement a Sealing Strategy in Your Shipments?

You've bought the right seals, but you have no formal process. Seals are applied inconsistently, numbers aren't recorded properly, and the entire system is too chaotic to be effective.

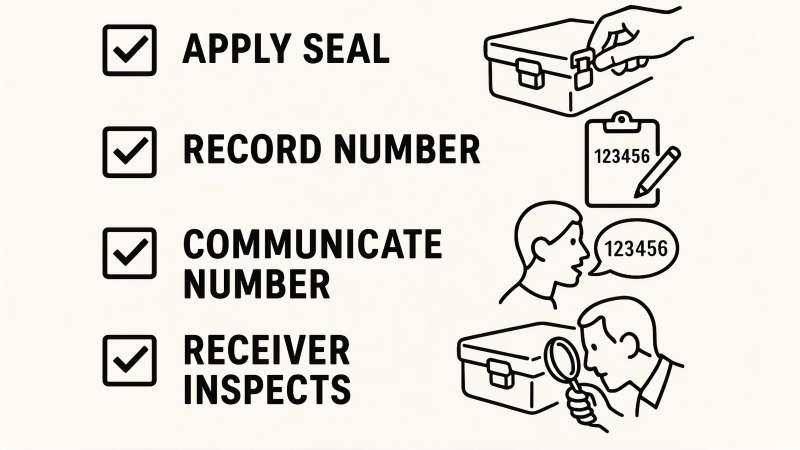

An effective sealing strategy is a formal, documented company procedure, not a casual task. It must clearly define who is responsible for applying the seal, how the number is recorded and communicated, and what the receiver must do upon inspection.

A strategy that isn't written down is just a suggestion. To get real value, you need to implement a formal Standard Operating Procedure (SOP). It must include these four steps:

- Application Protocol: Define who has the authority to apply the seal (e.g., the warehouse manager). The seal should be applied immediately after loading is complete and the doors are closed.

- Recording Protocol: The seal number must be recorded in at least two places: on the driver's manifest and in your own internal shipping log. Taking a clear photo of the locked seal with its number visible is also a best practice.

- Communication Protocol: The seal number must be communicated to the end consignee before the shipment arrives. This is crucial. It tells them what to look for and what number to expect.

- Inspection Protocol: Instruct your consignee what to do. They must physically check that the seal is intact and that the number matches the one you provided. If there is a discrepancy, they should not open the container and should contact you immediately.

Conclusion

Sealing in logistics is not about locking a door; it's about creating a "snapshot of innocence." This verifiable record is your most powerful tool for deterring theft, managing risk, and building trust with your partners and customers.

Create Your Snapshot of Security with ProtegoSeal

Implementing a professional sealing strategy is the first step toward a more secure supply chain. At ProtegoSeal, we provide the high-quality seals and expert guidance you need to protect your cargo. Contact us to create a sealing solution that delivers certainty and peace of mind.