A customer returns a "faulty" product they've secretly opened and damaged, forcing you into expensive, fraudulent claims. You have no way to prove they broke the rules.

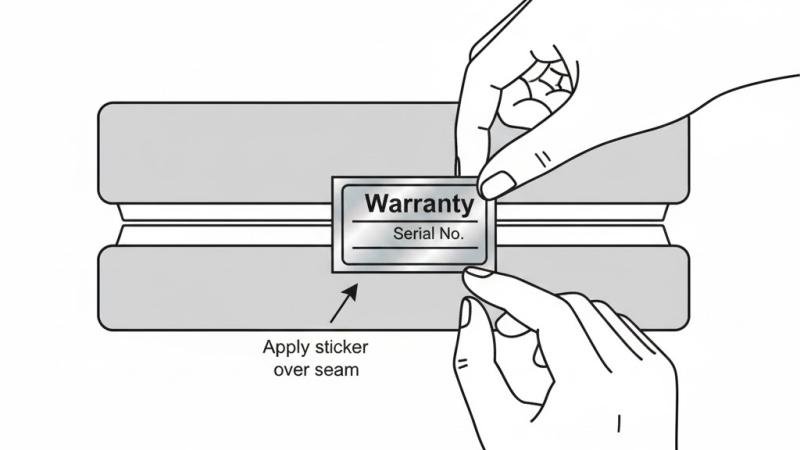

A warranty void sticker is a tamper-evident label placed over a seam or enclosure screw. When removal is attempted, the sticker self-destructs, leaving behind clear, irreversible visual evidence that the device has been opened, protecting you from unfair warranty claims.

For years, I thought there was some special magic to "warranty void" stickers. My breakthrough came when I realized the secret isn't what the sticker is, but where you put it and why. It's a high-tech tamper-evident label, yes, but it gets its special identity purely from its job. It’s an engineered, single-use security device whose entire purpose is to be the one and only witness to an unauthorized opening.

Why Is It Called a "Warranty Void" Sticker?

You have standard tamper-evident labels. So what transforms one into a "warranty void" sticker? It seems like just a name, but the difference has real authority.

It’s called a "warranty void" sticker because of its strategic placement over a product's access point, like a case seam or screw. Its sole purpose is to act as a silent witness. The name comes from its specific job, not its underlying technology.

The key insight is this: the physical label itself could be used for anything. It's the context that gives it power. A sticker is just a sticker until you give it a mission. By placing it over the only entry point to a product's sensitive internals, you are officially designating it as your line of defense against tampering. Its name is a direct reflection of the consequence it represents.

Identity Based on Placement and Purpose

The sticker itself is a versatile tool. Its "identity" is defined by its application. Let's look at how the same technology serves different purposes.

| Technology | Placement | Assigned Identity & Purpose |

|---|---|---|

| Destructible Vinyl Label | Seam of a game console | Warranty Void Sticker: To prove unauthorized opening for warranty control. |

| Destructible Vinyl Label | Lid of a confidential envelope | Evidence Seal: To prove a document has been seen by unauthorized parties. |

| Destructible Vinyl Label | Cap of a pill bottle | Safety Seal: To assure the consumer the product is factory-sealed and safe. |

As you can see, the exact same label becomes a "warranty void" sticker only when its placement and purpose align with protecting a product's warranty terms.

How Does the Label Leave Indelible Proof of Tampering?

If your sticker can be peeled off cleanly with a hairdryer or a razor blade, it offers no protection. It's just a bluff that experienced fraudsters will call instantly.

A true warranty void label leaves indelible proof through one of two main technologies: it either fractures into tiny, impossible-to-reassemble pieces (destructible vinyl) or it leaves a permanent "VOID" text pattern on the product surface (tamper-evident polyester). Both methods make tampering obvious.

These technologies are the engine that makes the sticker's security promise a reality. They are engineered to ensure that the bond of the adhesive is stronger than the integrity of the label material itself. There is no discreet way to defeat them.

Comparing the Core Technologies

Ultra-Destructible Vinyl (UDV):

- How it Works: The material is extremely brittle, almost like an eggshell. Any attempt to peel it causes it to fracture into dozens of tiny fragments.

- Best For: Curved or uneven surfaces, as the material is more flexible before application.

- The Evidence: A chaotic, shattered mess that cannot be pieced back together. Perfect for situations where you need to show overwhelming evidence of tampering.

"VOID" Polyester (Tamper-Evident PET):

- How it Works: The label is made of multiple layers. When peeled, a pre-designed pattern in the adhesive layer splits, leaving part of it on the product surface, typically spelling out "VOID" or "OPENED".

- Best For: Flat, smooth surfaces where a clean, unambiguous message is desired.

- The Evidence: A clear, linguistic message of tampering. It's less messy and provides a simple "yes/no" answer to the question, "Was this opened?" This technology is a form of security printing.

Key Application Areas for Warranty Void Labels

You understand the technology, but where does it actually make a difference? Placing a sticker in the wrong spot can make it useless or easily bypassed.

Warranty void labels are most effective when they seal the critical access points of high-value goods. Key areas include electronics enclosures, software packaging, sensitive equipment calibration ports, and pharmaceutical containers, where integrity is paramount.

In my experience, the most successful applications are always the most specific. I once worked with a company that manufactured high-precision scales. They had a problem with customers opening the device to try and bypass the weight limits, which would de-calibrate the instrument. We didn't place the sticker on the main case; we placed a tiny, custom-sized destructible label directly over the one screw that provided access to the calibration circuit. This surgical placement instantly solved 90% of their fraudulent warranty claims.

Prime Locations for Application:

- Electronics: Sealing the seams of casings for smartphones, laptops, game consoles, and hard drives.

- Physical Media: Sealing the opening of CD, DVD, or software boxes to prevent copying and repackaging.

- Calibrated Instruments: Covering access screws to tuning or calibration controls on scientific or industrial equipment.

- Automotive Parts: Sealing Electronic Control Units (ECUs) and other high-value components to deter unauthorized modifications.

- Access Panels: Any panel or door that protects sensitive or dangerous internal components.

Does a Broken Sticker Really Mean an Instant Voided Warranty?

A customer claims you can't void their warranty just because of a broken sticker, citing consumer rights. This puts you in a tricky legal and customer service gray area.

In many regions, like the U.S., a broken sticker alone cannot legally void the entire warranty, thanks to laws like the Magnuson-Moss Warranty Act. However, the sticker serves as powerful evidence. It shifts the burden of proof. It allows you to say, "This sticker proves the device was opened. We will now inspect for user-inflicted damage."

This is a crucial distinction that turns the sticker from a legal liability into a strategic tool. The sticker isn't a "contract"; it's a "data point." It doesn't automatically win the argument, but it gives you the undeniable starting point to investigate a warranty claim properly.

How to Use the Sticker Correctly:

- It's an Investigative Tool, Not a Final Verdict: Train your returns department to see a broken sticker as a red flag that triggers a deeper inspection, not an automatic rejection.

- Prove the Link to Damage: If the sticker is broken, your job is to demonstrate that the customer's unauthorized entry caused the fault they are claiming. For example, a broken seal and a spilled-soda stain on the motherboard.

- Clear Warranty Policy: Your warranty terms should clearly state that damage caused by unauthorized service or modification is not covered. The sticker is your primary tool for detecting that unauthorized service.

By using the sticker as evidence rather than an absolute rule, you stay on the right side of the law while still powerfully deterring fraudulent claims.

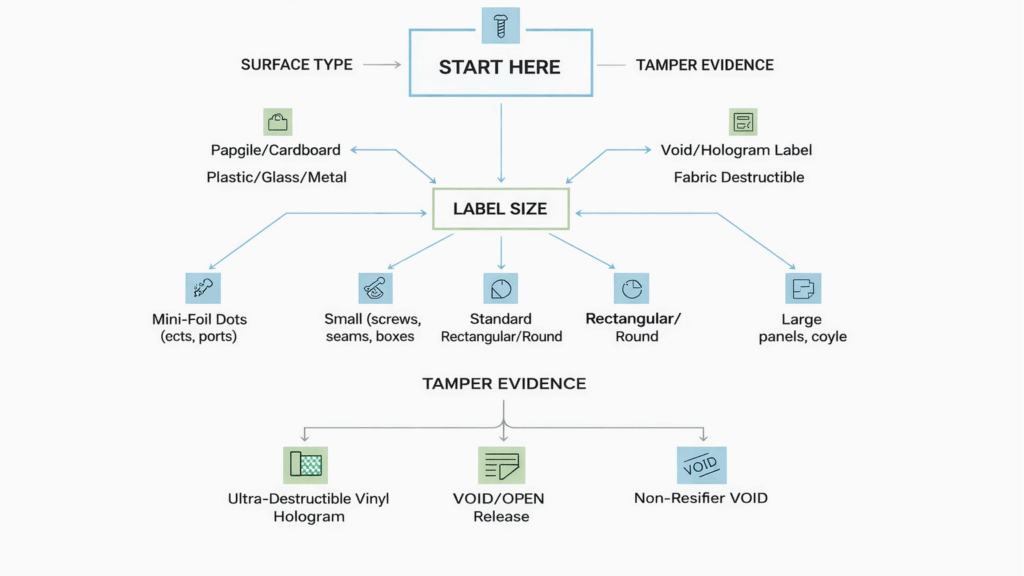

Choosing the Right Warranty Label for Your Product

You need to select a sticker, but the options are overwhelming. Picking one that's too big, too weak, or the wrong material can make your entire security effort pointless.

Choosing the right label depends on your product's surface, size constraints, and the type of evidence you want to leave. Match the technology (destructible vs. VOID) to the surface (smooth vs. textured) and the message you want to send.

I guide clients through a simple three-question process to nail down the perfect choice:

- What is the Surface Like? Is it a flat, smooth plastic or metal? A "VOID" polyester label is perfect. Is it a textured plastic or a curved edge? The more conformable destructible vinyl is a better choice.

- How Much Space Do You Have? Are you sealing a tiny screw hole or a long case seam? Labels can be die-cut to any shape or size, so measure the target area precisely. A label that's too big is easy to bypass.

- What Story Does the Evidence Need to Tell? Do you need a clean, simple "OPENED" message for a commercial environment (VOID Polyester)? Or do you need to show a chaotic, indisputable mess that screams "someone tore this open" (Destructible Vinyl)?

Thinking through these questions ensures the label you choose will perform its specific security job flawlessly.

Conclusion

A warranty void sticker gets its power from its specific placement and purpose. It’s a tamper-evident technology deployed as a single-use witness, providing the crucial evidence you need to fairly manage warranties.

Deploy Your Warranty Protection Strategy with ProtegoSeal

Don't let warranty fraud eat into your profits. From ultra-destructible vinyl to custom "VOID" patterns, ProtegoSeal can provide the perfectly engineered label for your product's specific needs. Contact us to build your line of defense.