A container arrives with a suspect seal, or worse, no seal at all. Who's responsible for the potential loss? Without clear proof, your supply chain has a critical, and very expensive, blind spot.

A bolt seal is a single-use, high-security locking device primarily used to secure shipping containers and truck trailers. It functions as a forensic tool, designed to be destroyed upon removal, providing undeniable physical evidence of access and locking in accountability between parties.

Many clients initially think a high-security bolt seal is a defense tool, like a padlock. But I always reframe it for them: its core purpose is not to be indestructible, but to serve as a forensic tool. Its design brilliance lies not in preventing entry forever, but in being destroyed in a clear, non-repairable way a single time. This provides absolute, irrefutable evidence of tampering. A bolt seal doesn't just lock cargo; it locks responsibility. It is the standardized, physical "handshake" that transfers accountability from one party to the next in the supply chain. Let’s dive into how it achieves this.

Deconstructing the Bolt Seal: How Its Pin and Body Design Provides Top-Level Security

A thief attacks your seal, tries to glue it back together, and hopes nobody notices. But this simple trick can cost you everything if it works.

It won't work with a quality bolt seal. Its internal mechanism is designed to break permanently upon being forced open, making stealthy reassembly impossible and leaving obvious evidence of the attack.

The magic of the bolt seal is in its deliberate, one-way engineering. It's a perfect example of a design that prioritizes evidence over simple resistance. I've spent over a decade examining these devices, and their effectiveness comes down to a few key principles.

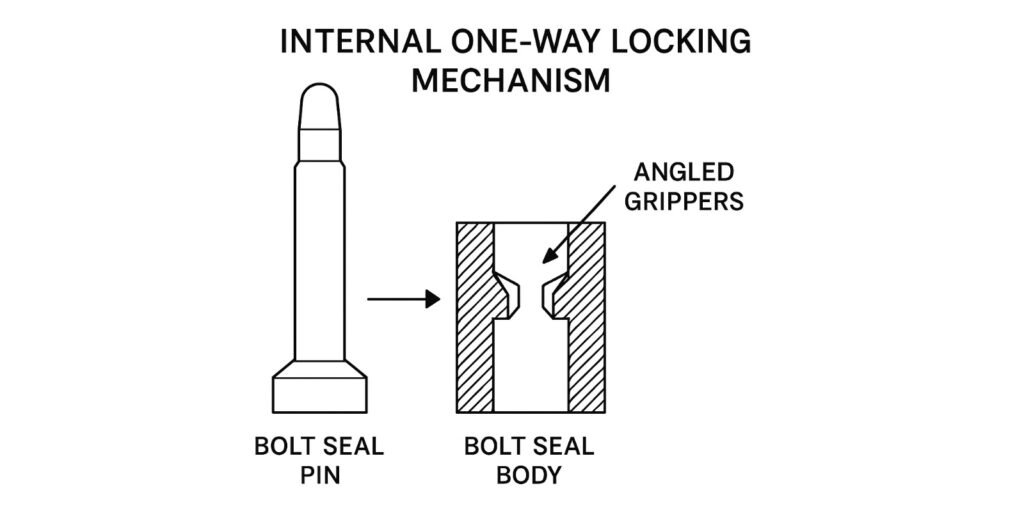

The Pin and Bushing: A One-Way System

The seal consists of a hardened steel pin and a separate locking body (or bushing). When you push the pin into the body, you hear a "click." That is the sound of an internal spring-loaded steel split ring snapping into a groove on the pin. Once engaged, it cannot be pulled back out without destroying the lock's internal structure. It’s mechanically a one-way street.

Designed for Forensic Evidence

This is where the "forensic tool" concept comes to life. The entire seal is designed to fail in a very specific, highly visible way.

- Anti-Spin Features: High-quality seals have shaped pins and bushings (e.g., square or hexagonal) that prevent a thief from spinning the pin at high speed with a drill to try and friction-weld or break the internal lock.

- Clear Tamper Indication: Cutting the pin requires heavy-duty bolt cutters, leaving obvious marks. Trying to pull it apart will deform the steel or break the internal ring. There is no subtle way to defeat it.

What Does "High-Security Seal" Actually Mean? Unpacking the ISO 17712 Standard

A supplier offers you "high-security" seals without any certifications. How do you know they aren't just colored pieces of metal that offer no real security?

The term "high-security" is meaningless without independent proof. It is officially defined by ISO 17712, an international standard that certifies a seal has passed rigorous strength and tamper-evidence tests in a lab.

When I explain this to clients, I call the ISO 17712 standard the "common language of responsibility." It ensures that a bolt seal from a factory in China and one from a factory in Germany offer the same, verifiable level of security. This is what allows it to act as a standardized "receipt" for transferring accountability. To earn the "H" classification (High-Security), a seal must pass a series of brutal tests.

Key ISO 17712 "H" Tests

| Test Type | Purpose | Why It Matters |

|---|---|---|

| Tensile (Pull) Test | Measures the force required to pull the locked seal apart. Must withstand over 1,000 kg (2,205 lbs) of force. | Ensures it won't break from the normal shocks and stresses of transit or be easily forced apart. |

| Shear Test | Measures the force needed to cut the pin with a shearing tool. | Simulates an attack with cutters, guaranteeing a minimum level of physical resistance. |

| Impact Test | The locked seal is subjected to powerful impacts at extreme temperatures (-40°C and +55°C). | Proves the seal's materials won't become brittle and shatter in cold or soften in heat. |

An ISO 17712 "H" rating is your proof that the seal is a genuine forensic tool, recognized by customs organizations like C-TPAT worldwide.

When and Where is a Bolt Seal the "Only Choice"? (Common Applications)

You're shipping by sea and by rail. Can you get away with a cheaper cable seal, or are there situations where only a bolt seal will do?

For cross-border freight and container shipping, a bolt seal isn't just the best choice; it's often the only choice. Customs regulations and the high-risk nature of these routes demand it.

From my experience, while cable seals are incredibly versatile, the bolt seal is the undisputed king in specific, high-stakes environments. These are scenarios where the "locking of responsibility" is paramount.

Core Applications for Bolt Seals

- All Cross-Border Shipping Containers: This is the primary application. When a container is sealed at a factory in one country, that seal must remain intact until it is broken by an authorized customs agent or the final recipient in another country. The ISO 17712 "H" rated bolt seal is the global standard for this.

- Long-Haul Rail Freight: Railcars can pass through dozens of unsecured yards on a cross-country journey. The high barrier strength of a bolt seal deters tampering during these long, unsupervised trips.

- High-Value Truckload Shipments: For domestic shipments of extremely high-value goods (like electronics or pharmaceuticals), a bolt seal provides the ultimate level of cargo security and acts as a powerful deterrent against organized cargo theft rings.

In these cases, the bolt seal serves as an unambiguous contract. If Seal #12345 is intact, the carrier did its job. If it's not, the responsibility is clear.

How to Properly Apply and Verify a Bolt Seal for Maximum Security?

You've bought the best bolt seals, but your team just clicks them on and forgets them. An incorrect application makes even the most expensive seal completely useless.

Proper security is a process, not just a product. To get a bolt seal's full forensic value, you must apply it correctly and document it as part of a strict "seal protocol."

This is where the "responsibility handshake" happens in the real world. A seal is only as good as the procedure that governs it. I always stress a simple, four-step process.

The 4-Step Seal Protocol

- Record the Number: Before application, the shipper records the unique, matching serial numbers on both the pin and the locking body in the shipping documents (e.g., the Bill of Lading).

- Apply Correctly: Thread the pin through the container door latch hardware. Push the pin firmly into the locking body until you hear a loud, satisfying "CLICK."

- Verify the Lock (The "Tug Test"): This is the most critical step. Grab both the pin and the body and pull on them forcefully. A correctly locked seal will not come apart. If it does, it was defective or not fully engaged. Discard it and use a new one, recording the new number.

- Confirm at Destination: The recipient checks that the seal number matches the shipping documents and that the seal shows no signs of tampering before breaking it. This officially completes the transfer of responsibility.

What Are the Key Advantages of Using a Bolt Seal?

You're trying to justify the higher cost of a bolt seal over a plastic one. What specific, bottom-line benefits can you point to?

The value is not in the cost of the seal but in the cost of the disaster it prevents. A bolt seal offers unparalleled tamper evidence, clear accountability, and regulatory compliance.

When a client weighs their options, I always summarize the advantages of a bolt seal by connecting them back to our core ideas. A bolt seal is an investment in certainty.

The 3 Core Pillars of a Bolt Seal's Value

- Undeniable Forensic Evidence: Unlike other seals, a bolt seal cannot be subtly defeated. Any attack leaves a permanent, obvious record. This eliminates arguments and ambiguity, simplifying insurance claims and internal investigations. It answers the question, "Was this tampered with?" with a simple yes or no.

- Clear Accountability: Because the seal number is logged at every step, it creates a bulletproof audit trail. It pinpoints exactly where in the supply chain a problem occurred. This shifts blame from a company-wide problem to a specific point of failure, protecting innocent parties.

- Guaranteed Compliance: Using an ISO 17712 "H" rated bolt seal is the fastest way to meet customs and security requirements for international trade programs. It prevents costly delays, container inspections, and fines at the border.

Conclusion

A bolt seal is more than a lock; it is a critical forensic device. It is engineered to provide undeniable proof of tampering, serving as the physical handshake that transfers responsibility and secures your entire supply chain.

Secure Your Responsibility with ProtegoSeal

Ready to move from ambiguity to certainty? At ProtegoSeal, we specialize in ISO-certified bolt seals that serve as the forensic backbone of your logistics. Contact us to build a security program based on clear accountability.