Are you unknowingly bleeding profits because your current security seals can be peeled off and reapplied without a trace? Invisible pilferage doesn't just steal your cargo; it destroys your reputation and creates liability nightmares where you cannot prove who opened the box.

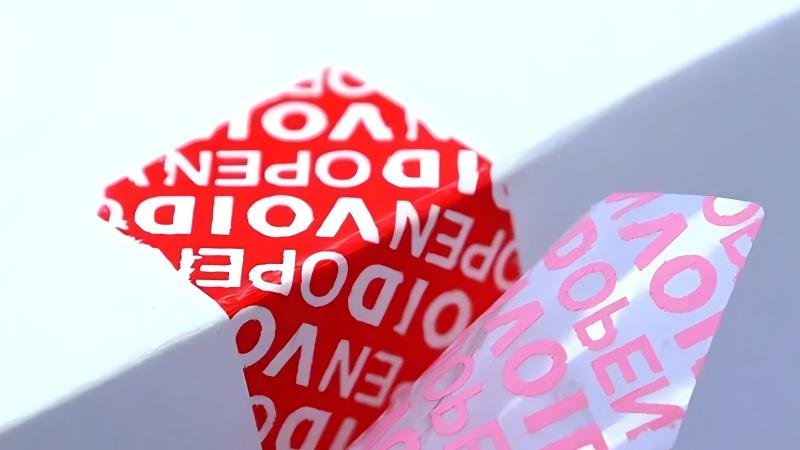

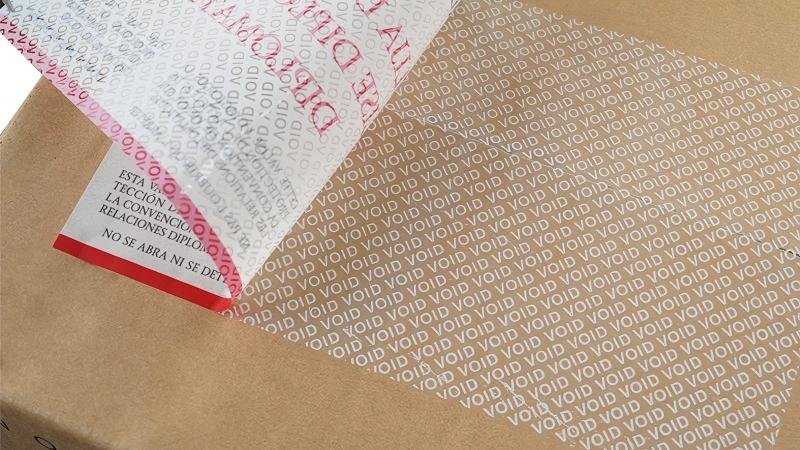

A High-security VOID label stops this vulnerability by acting as a calibrated "evidence system." It complies with strict supply chain protocols—such as those outlined by C-TPAT (Customs-Trade Partnership Against Terrorism)—utilizing differential release mechanics to self-destruct upon removal. This instantly converts a concealed tamper attempt into a permanent, high-contrast forensic alert that makes theft undeniable.

I need to be very clear about something: the core technology here isn't about adhesion, but about controlled delamination. As a manufacturer, I characterize these labels by their "break force" versus their "peel force." A standard label is designed to stay intact. A high-security VOID label is chemically engineered to bond with the substrate (the box) more strongly than it bonds to its own internal layers. This deliberate structural weakness ensures that any attempt to remove the label triggers an irreversible state change, transitioning it from a packaging component to a piece of forensic evidence.

The Core Mechanism: How Layered Technology Reveals the Hidden Message?

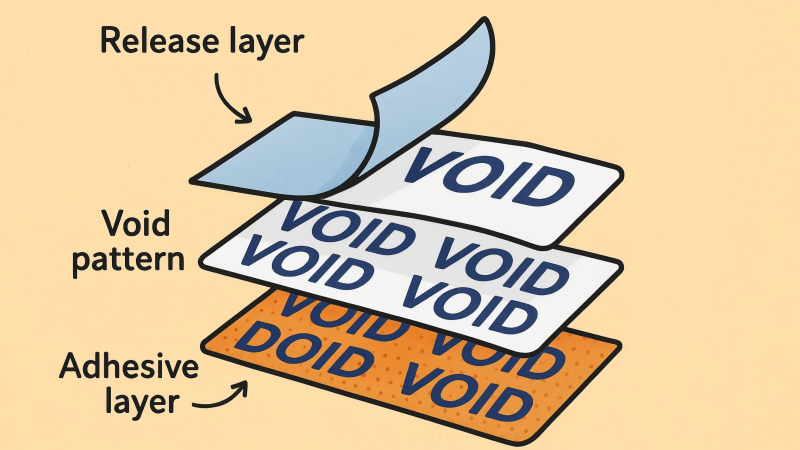

Ever wondered how that "VOID" message physically separates from the film? It is the result of differing surface tensions on a microscopic scale.

A VOID label is constructed like a sandwich with a "fault line" engineered into the middle. The system utilizes a release coating (silicone or wax-based) with a specific release value; when peel force is applied, the bond breaks exactly at the pattern interface, leaving the message behind while the film lifts.

The Physics of Differential Release

To understand the "Why," we must look at the cross-section of the manufacturing process. A standard label has two functional layers: the face stock and the adhesive. A tamper-evident label introduces a critical third variable: the patterned release liner.

We treat the back of the face film with a release agent in a specific pattern (the word "VOID"). Then, we apply the adhesive over this pattern.

Here is the physics: The adhesive bonds aggressively to the substrate. The adhesive also bonds to the label's face film. However, the connection is weakened specifically where the "VOID" pattern is printed. When stress is applied, it exceeds the tensile strength of that patterned area first. The adhesive in the "VOID" shape stays on the box, while the rest stays on the label. This is precision engineering where we calculate the mechanics of the break point.

The Key to Irreversibility: Unlocking Residue Transfer Technology?

What prevents a bad actor from simply wiping off the residue and pretending nothing happened? The security lies in the chemical curing process known as "wetting out," which makes the residue permanent.

The key to irreversibility is the acrylic-based adhesive formula. Unlike rubber-based adhesives that sit on top of a surface, engineered acrylics flow into the microscopic pores of the application surface, creating a mechanical lock that is impossible to reverse without solvents.

Chemical Bonding and Dwell Time

This is where the science of "Dwell Time" becomes critical. I always advise clients that a VOID label is not structurally fast. It needs time to "wet out."

Under a microscope, even a smooth cardboard box looks like a mountain range. The adhesive needs time to flow into these valleys. Once it cures (usually achieving 90% strength within 20 minutes), the residue becomes part of the substrate.

If a thief tries to use solvents like acetone to clean the residue, they face a double-edged sword. High-security adhesives are typically solvent-resistant. The cleaning attempt usually smears the residue or dissolves the substrate's ink, creating "Secondary Evidence"—proof of a chemical attack.

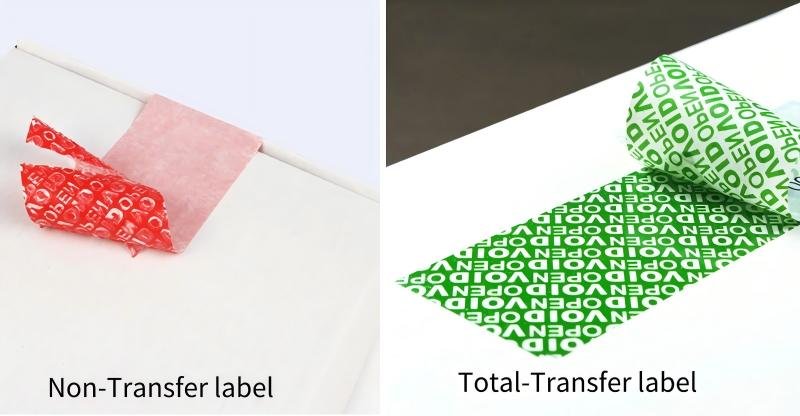

Forms of Evidence: A Full Breakdown of Total-Transfer vs. Non-Transfer?

Did you know that the "mechanics of transfer" must be matched to the material properties of the asset?

The industry classifies these mechanisms into two primary categories: Total-Transfer, which relies on cohesive failure to leave residue, and Non-Transfer, which relies on internal film fracture to reveal a message without leaving debris.

Matching Mechanics to Application

Choosing the wrong transfer mechanism results in security failure. This is determined by the "Surface Energy" of the application.

- Total-Transfer (High Residue): Best for porous surfaces (cardboard, wood). The mechanic here is mechanical interlocking. The glue flows into fibers, creating a bond stronger than the label's internal strength.

- Non-Transfer (Zero Residue): Essential for non-porous, high-value surfaces (glass, aircraft doors). The mechanic here is inter-layer separation. The bond to the car door is strong, but the bond between the label's color layer and base layer is weaker. When peeled, the label splits internally. The car door stays clean, but the label is destroyed.

| Feature | Total Transfer | Non-Transfer |

|---|---|---|

| Residue Mechanic | Cohesive failure (leaves glue) | Internal fracture (leaves nothing) |

| Primary Target | Cardboard, Pallets, Paper | Glass, Metal, Painted Plastic |

| Security Indicator | Residue on the box | "VOID" on the label face |

| Cleanup Required | Yes (Chemical removal) | No |

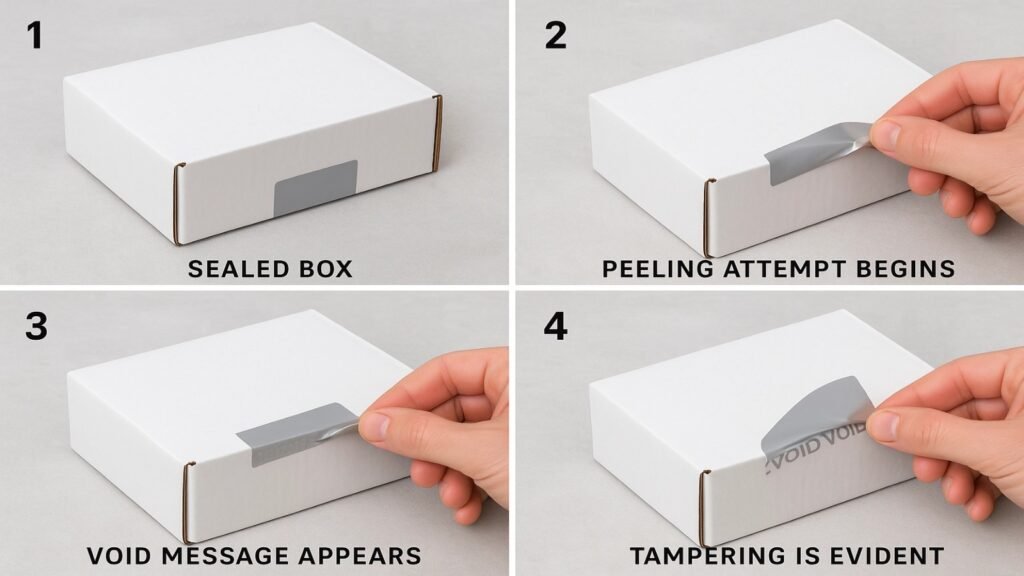

From Theory to Reality: How a Tamper Attempt Triggers the Evidence Chain?

How does this calibrated system react to environmental attacks like freezing or heating?

The evidence chain is triggered by physical stress or thermal flux. High-quality VOID labels utilize strictly tested pressure-sensitive adhesives (PSA) that maintain their failure point even when subjected to extreme temperatures, preventing "lift and replace" attacks.

Defeating the "Thermal Attack"

Thieves often use hair dryers (heat) or refrigerant spray (cold) to manipulate the material's elasticity.

- Heat Attack: Heat softens standard glue. However, engineered security adhesives are cross-linked. When heated, the carrier film expands at a different rate than the adhesive layer (thermal expansion coefficient mismatch). Result: The shear stress triggers the VOID message prematurely before the glue softens.

- Cold Attack (Freon): Freezing attempts to make the adhesive brittle. Leading manufacturers use wide-temperature range adhesives (-40°C to +80°C). Even if frozen, the brittle adhesive will "shatter" in a fractal pattern rather than peeling cleanly. This "shattered" look provides distinct forensic evidence of a cryogenic attack.

Ensuring Evidence Integrity: The Critical Match Between Surface and Adhesive?

Why do some expensive security labels fail to trigger the VOID mechanism on plastic containers? The failure is usually due to mismatched Surface Energy (Dyne level).

For the mechanism to work, the adhesive's bond to the substrate must exceed the label's internal cohesion. Low surface energy materials like Polypropylene (PP)] naturally repel adhesives, requiring a specialized "high-tack" chemical formula tested against rigorous ASTM International standards.

The "Dyne Level" Factor

This is the technical nuance that separates a professional specification from a guess. Surfaces have energy, measured in Dynes/cm.

- High Energy (Metals, Glass): Easy to wet out. The adhesive flows deeply.

- Low Energy (PP Totes, Powder Coating): These surfaces are "slippery" at a molecular level. If you use a standard label, the adhesive won't grip sufficient to trigger the break. When peeled, the label lifts off intact (false negative). The system fails because the anchor force was too low. I always stress testing the specific Dyne level of your packaging. If you are using recycled plastic crates, you cannot use a cardboard-grade label.

Conclusion

A VOID label is a calibrated chemical reactor, not a sticker. By understanding the mechanics of differential release, selecting the correct transfer method, and matching the adhesive chemistry to your surface energy, you engineer an irreversible evidence system.

Calibrate Your Evidence System with ProtegoSeal

Don't guess when it comes to engineering security. At ProtegoSeal, we specialize in the science of adhesion verification. We utilize lab-tested differential release technologies to ensure your evidence chain remains unbreakable. Contact us today for a technical compatibility test.