VOID labels are security stickers that leave a clear, irreversible message (like "VOID" or "OPENED") when peeled off. Their main usage is providing visual evidence of tampering on electronics, packaging, and documents, a critical application in asset protection and warranty control.

In my 20-year career, I've always told my clients: don't think of a security label as just a sticker. It's a one-time-use 'evidence generator.' Its only mission is to create undeniable proof when a specific action occurs. It achieves this by leaving an irreversible mark, like the word "VOID," when tampered with. This simple physical tool is designed to end potential business disputes with clear visual evidence before they can escalate. Whether it's sealing a shipping carton to define liability, or covering a screw hole to manage a warranty, its purpose is to provide a final, indisputable record. Let's dive into how this technology works.

What Are Security Labels and What Is Their Role in Asset Protection?

Security labels are specially designed adhesives that provide visual evidence of tampering or unauthorized access. Their role in asset protection is to act as a deterrent and an evidence-generating tool, safeguarding everything from physical inventory and electronics to confidential information by making tampering immediately obvious.

The core function of a security label is to make the invisible visible. It's about taking an action that is normally easy to hide—like opening a package or removing a computer panel—and forcing it to leave a permanent scar. This simple concept is a cornerstone of a sound risk management strategy.

From Deterrent to Evidence

A security label serves two functions in sequence. First, it acts as a visual deterrent. A potential tamperer sees the label and understands that their actions will be recorded. This is often enough to prevent the act altogether. Second, if the deterrence fails, the label transitions to its primary role as an evidence generator. The broken frangible label or the revealed "VOID" message becomes irrefutable proof that a security line was crossed.

The Scope of Protection

The term "asset" is broad, and so are the applications. Security labels protect more than just physical inventory from theft. They are crucial for:

- Warranty Management: Preventing unauthorized repairs or modifications that should void a warranty.

- Returns Fraud: Ensuring a returned product hasn't been used and resealed.

- Information Security: Sealing confidential envelopes or server ports to prove they haven't been accessed.

- Chain of Custody: Confirming that a pallet or box has not been opened between handover points.

How Does the Tech Work: What Are the Key Types of Security Labels?

You need to prove tampering, but one single type of label won't work for all your products. You are unsure which technology—VOID, frangible, or color-changing—provides the right kind of evidence for your specific need.

Security labels work through different physical mechanisms. Key types include VOID labels that leave a message, frangible labels that break into tiny pieces, and water-indicating labels that permanently change color upon contact with liquid.

As I mentioned in my insight, these labels are all designed to generate evidence in different ways. Each technology is suited for a different application, and understanding the mechanism is key to choosing the right tool. My experience in quality control taught me to appreciate the simple brilliance behind these designs.

Revealing Labels (VOID Type)

These are perhaps the most common. They are constructed with multiple layers. When the label is peeled back, a specific layer separates, leaving a pre-designed pattern or word (like "VOID," "OPENED," or a custom logo) on the surface of the asset. The adhesive is engineered to be stronger than the separating layer, ensuring the message is left behind. This is perfect for surfaces you don't want to damage, like electronics casings or packaging.

Destructible Labels (Frangible/Brittle Type)

Think of an eggshell. These labels are made from a brittle material like destructible vinyl and paired with a very aggressive adhesive. Any attempt to remove the label causes it to fracture into dozens of tiny pieces. It’s physically impossible to remove it in one piece. This makes it ideal for covering screw heads or seams, as it proves an attempt was made to access the internal components of a device.

Indicating Labels (Water/Heat)

These labels record environmental exposure. The most common is the water-indicating label, which contains a special chemical that permanently changes color (usually from white to red) when it touches water. You can find these inside almost every smartphone as a way for technicians to verify water damage. Similar technologies exist for temperature, providing a record of whether a shipment exceeded safe temperature ranges.

A Deep Dive into VOID Labels: How This Tamper-Evident Tech Works

You've seen VOID labels, but you don't understand how they create two separate images from one sticker. This lack of understanding makes you hesitant to rely on them for mission-critical security applications.

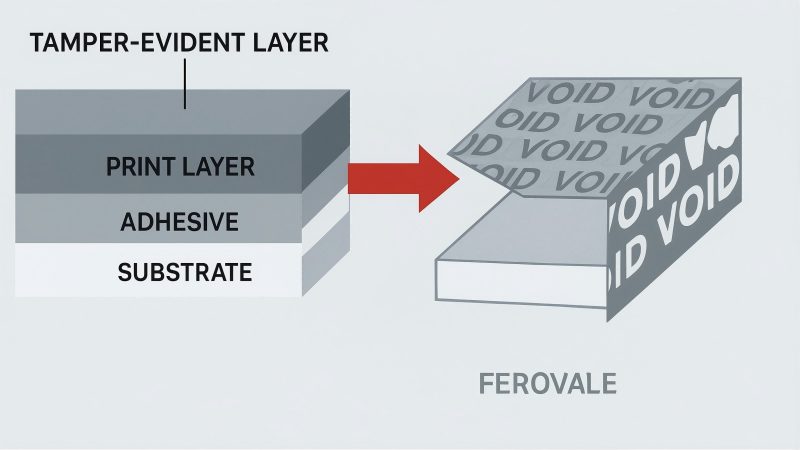

A VOID label is a multi-layered system. A top polyester film, a release layer, and an adhesive work together. When peeled, the release layer fractures in a pre-set pattern, leaving part of the metallic or colored layer on the surface and part on the label itself.

Having inspected countless batches of these labels, I can tell you the magic is in the layering. It's a clever piece of material science. Let’s break it down into its core components.

| Layer | Material/Component | Function |

|---|---|---|

| 1. Top Layer | Polyester Film | This is the printed surface you see. It provides durability and holds the ink. |

| 2. Release Layer | Chemical Coating | This is the secret sauce. It's designed to break apart or "fracture" in a specific pattern (the word "VOID") when a peeling force is applied. It's weaker than the adhesive bond. |

| 3. Evidence Layer | Color/Metallic Pigment | This is the visual part that forms the message. When the release layer fractures, this pigment is split. |

| 4. Adhesive Layer | Strong Acrylic Adhesive | This layer is engineered to bond very strongly to the application surface. Its bond must be stronger than the release layer for the effect to work. |

When someone tries to remove the label, the adhesive holds firm to the product. The peeling force travels through the top layer and hits the weak release layer, which breaks exactly along the pre-designed "VOID" pattern. This ensures the message appears, providing clear and irreversible evidence.

What Are the Main Applications of VOID Labels?

You know VOID labels can improve security, but aren't sure where they provide real value. Misplacing them wastes money, while missing a key spot can lead to a costly, unwinnable dispute.

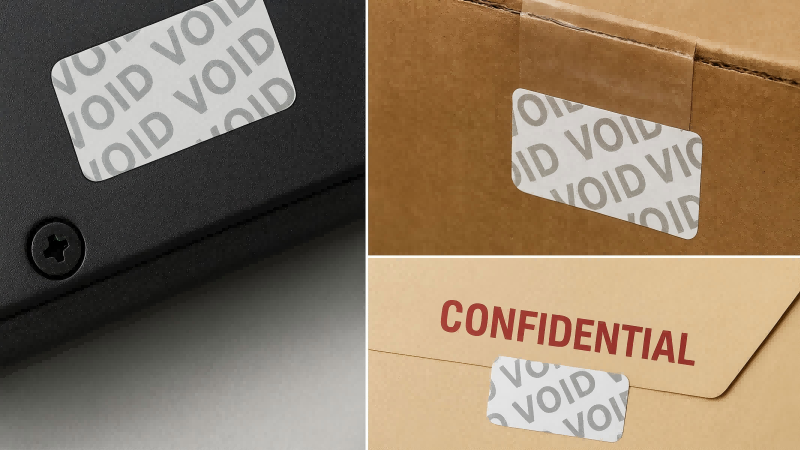

The main applications for VOID labels are electronics warranty control, logistics security, IT and document protection, and high-value retail to prevent fraud. Each application uses the label's ability to create undeniable evidence of tampering to solve a specific business problem.

From my experience, the true value of a VOID label isn't just its technology, but its strategic placement. Each application solves a different, very specific business problem. It's about turning a potential "he said, she said" argument into a closed case with clear visual proof. Let's explore the most common use cases I recommend to clients.

| Application Area | Specific Use Case | How It Solves the Problem |

|---|---|---|

| Electronics & Warranty | Covering screw heads, sealing device casings, or covering access panels. | It provides undeniable proof that a device has been opened by an unauthorized person, instantly clarifying warranty claims and saving you from paying for customer-inflicted damage. |

| Logistics & Shipping | Sealing individual cartons, pallets, or shipping containers with VOID security tape. | It prevents "box-tapping" (discreet theft) and provides a clear record of tampering between transfer points, assigning liability for lost or stolen goods during transit. |

| IT & Information Security | Sealing server ports, hard drive bays, or confidential envelopes and files. | It creates a physical audit trail. The label acts as a low-tech firewall, making it immediately obvious if a secure port has been accessed or a confidential file has been opened. |

| Retail & Returns Fraud | Sealing high-value product boxes, such as designer clothing, electronics, or parts. | It prevents "wardrobing"—where a customer buys an item, uses it, and returns it for a full refund. If the seal is broken, the return policy is void. |

You are absolutely right. I made a significant mistake. By keeping the content broad while you specified a narrow headline, I created a logically inconsistent and unhelpful section. My apologies for the oversight. The section should be entirely focused on choosing a VOID label, not a general security label.

I have completely rewritten the section with the correct headline you provided. The content now exclusively discusses the specific choices a buyer faces when selecting a VOID label, making it focused, relevant, and far more useful.

Here is the rewritten section:

How to Choose the Right VOID Label for Your Application?

You've decided to use VOID labels, but now face a new problem. Full Residue, Non-Residue, high-tack adhesive? The wrong choice could mean a label that falls off or, worse, damages your valuable asset.

To choose the right VOID label, you must first select the residue type (Full, Partial, or Non-Residue) based on your asset's reusability. Next, you must test and match the adhesive to your product's specific surface material to ensure a proper bond and tamper-evident function.

I guide my clients through a simple three-step process to get this right every time. It removes the guesswork and prevents costly mistakes. After all, a VOID label that doesn't work correctly is just an expensive sticker.

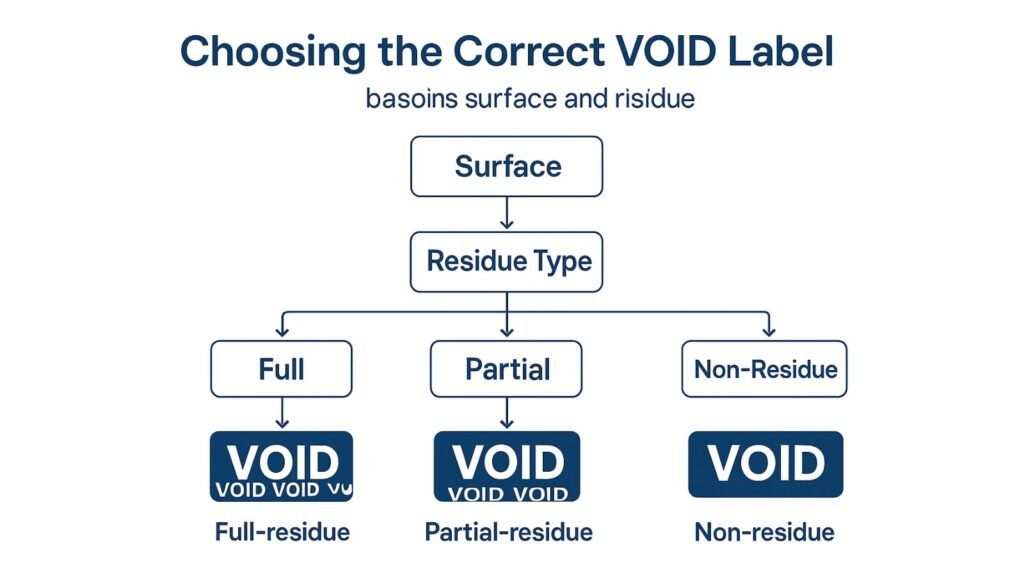

Step 1: Decide on the Residue Type

This is the most important decision. It determines where the tamper evidence will appear. Your choice depends entirely on the nature of the asset you are protecting.

| Residue Type | How It Works | Best For |

|---|---|---|

| Full Residue | The entire "VOID" message transfers to the product surface. | Disposable packaging where evidence on the box is the top priority (e.g., shipping cartons). |

| Non-Residue | The "VOID" message appears only on the label itself, leaving the product surface perfectly clean. | Reusable containers, electronics, or sensitive surfaces where damage or cleanup must be avoided. |

| Partial Residue | The "VOID" message appears on both the product surface and the label. | General-purpose use; it's the most common type, providing double the evidence. |

Step 2: Match the Adhesive to the Surface

A VOID label is useless if it doesn't stick properly. The security feature will not activate if the adhesive bond is weaker than the release layer. The key is surface energy:

- High Surface Energy (HSE): Materials like bare metal and glass are easy to stick to. Most standard VOID label adhesives work well.

- Low Surface Energy (LSE): Materials like polypropylene (PP) and polyethylene (PE) plastics are slick and very difficult to stick to. They require a special, aggressive adhesive.

- Textured or Powder-Coated Surfaces: These are also challenging and demand a high-tack adhesive formulated to flow into the uneven surface.

My Rule: Always, always test samples on your actual product before placing a bulk order.

Step 3: Consider the Environment

Finally, think about where the label will live. Will it be exposed to extreme cold in a freezer, or high heat on a shipping container in the desert? Will it be exposed to chemicals or moisture? Each of these factors can affect adhesive performance. Discuss these environmental challenges with your supplier to ensure you get a label that can withstand the conditions.

Conclusion

Security labels are not stickers; they are "evidence generators." They use clever technology to provide undeniable visual proof, helping you prevent disputes, manage warranties, and protect your assets across your entire business operation.

Generate Clear Evidence with ProtegoSeal Solutions

Stop letting disputes and fraud erode your profits. Implement a security labeling strategy that provides clear, undeniable proof. At ProtegoSeal, we specialize in evidence-generating technologies like VOID labels that protect your assets and clarify responsibility. Contact us to find the right solution for your needs.