Choosing the wrong trailer seal turns your truck into an easy target. Security managers must distinguish between a simple plastic indicator and a heavy-duty physical lock to prevent theft.

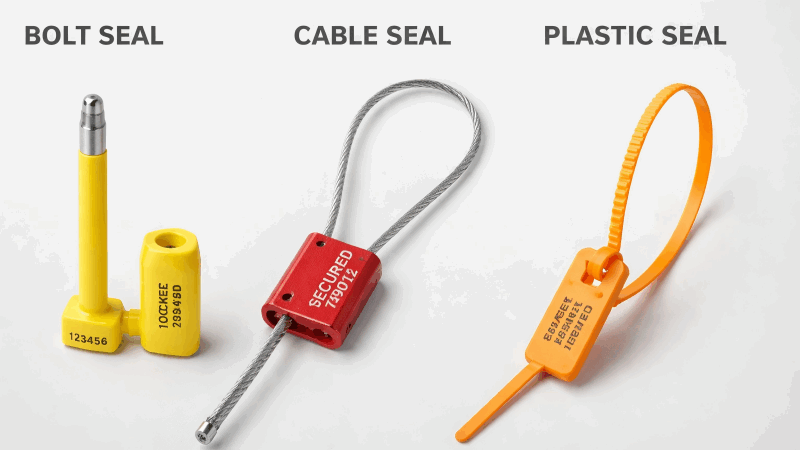

A trailer seal secures cargo doors against tampering. The three main types—Bolt, Cable, and Plastic—serve different roles: Bolt seals provide high-security locking, Cable seals fit irregular latches, and Plastic seals offer visual evidence only.

I often see logistics managers choosing seals based on price rather than physics. This is a fatal mistake. You cannot expect a polypropylene strip to stop a pair of bolt cutters, just as you cannot force a rigid steel bolt through a bent trailer hasp. As a manufacturer, I look at seals differently: I look at the tensile strength of the materials and the geometry of the application. The specific alloy of the steel pin and the weave of the cable determine if your cargo stays secure. You must match the seal's mechanical resistance to the threat level of your route.

The Structural Superiority of Bolt Seals for High-Risk Cargo?

Why are Bolt Seals the only option for cross-border shipments and high-value containers? Because they are not just seals; they are industrial-grade physical locks.

Bolt seals are engineered using hardened carbon steel pins and ABS plastic-coated locking bodies, providing a shear strength that exceeds 1,000 kg. This makes them the only category capable of meeting ISO 17712 High Security standards required for C-TPAT compliance.

The Physics of Anti-Spin Technology

The structural dominance of the Bolt Seal comes from its rigidity. It is designed to resist brute force. When we manufacture a High Security Seal, the steel pin is treated to prevent cutting with standard tools; thieves need heavy-duty bolt cutters (24-inch or larger) to remove it. This creates a significant time barrier. Furthermore, modern bolt seals feature "anti-spin" technology. The locking mechanism and the pin shape interact to prevent the seal from being rotated at high speed, a common method thieves use to unscrew cheaper seals.

C-TPAT and Regulatory Compliance

For any cargo entering the United States or moving through high-risk zones, the Bolt Seal is non-negotiable. The C-TPAT program (Customs-Trade Partnership Against Terrorism) explicitly requires seals that pass the ISO 17712 impact, shear, and bend tests. Using anything less provides a false sense of security. If your cargo is worth $50,000 or more, relying on anything other than a hardened steel bolt is negligence. It provides the "physical defense" layer that stops opportunistic criminals dead in their tracks.

Cable Seals: Versatility for Irregular Trailer Door Latches?

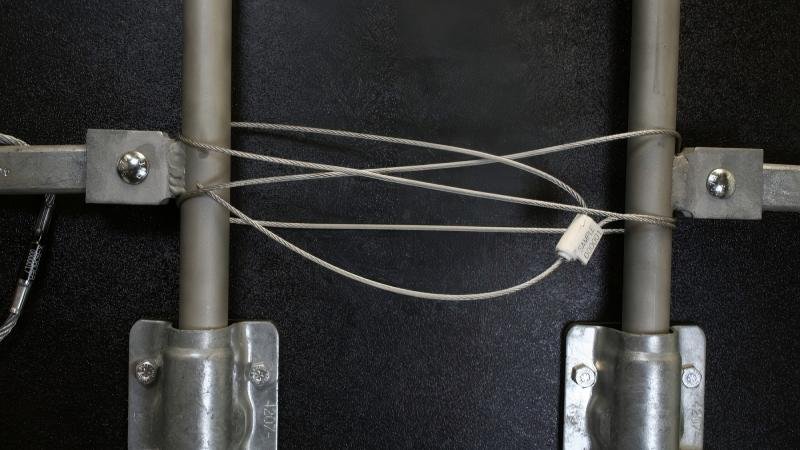

What do you do when the trailer door latch is bent, the holes are misaligned, or the hasp is too far apart for a rigid bolt? A rigid seal effectively becomes useless in these mechanical scenarios.

Cable seals utilize a woven galvanized steel wire that offers the physical strength of metal but the flexibility of a rope. This adjustable length allows them to thread through deformed locking mechanisms where rigid seals physically cannot fit.

Solving the "Geometry Problem"

I frequently visit logistics yards where older trailers have taken a beating. The locking bars are often bent, or the welding on the hasp has shifted. A Bolt Seal acts like a straight rod; if the holes don't line up perfectly, you cannot lock it. The Cable Seal solves this adaptability crisis. Its variable length (usually 30cm to over a meter) means you can loop it through difficult angles or secure valve handles on tank trucks.

The Strength of the Weave

Do not mistake flexibility for weakness. High-quality cable seals utilize "non-preformed" galvanized aircraft cable. This means if a thief cuts the cable, the wires splay out (unraveling wildly), making it impossible to re-join or glue back together. This is a brilliant manufacturing trick that turns the material's tension into a security feature. While they come in varying diameters (1.5mm to 5.0mm), a 3.5mm cable seal can rival a bolt seal in breaking strength, classifying it as "High Security" under ISO standards. It allows you to maintain a high physical defense even when the trailer hardware is fighting against you.

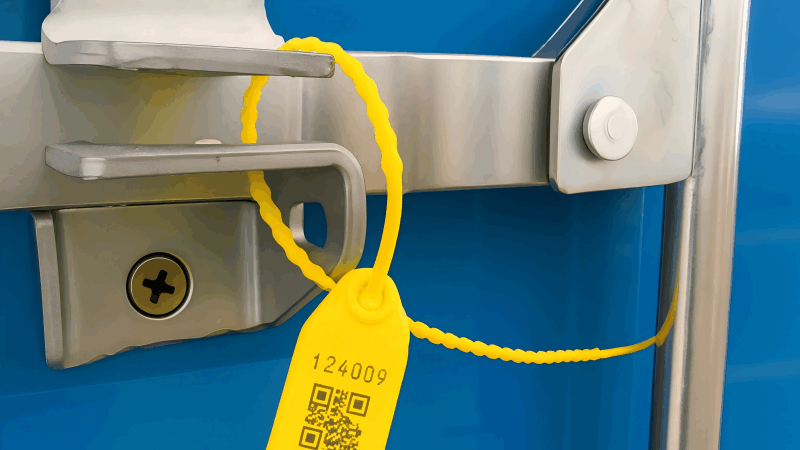

When is a Plastic Seal Sufficient for Trailer Security?

If plastic seals can be broken by hand or with simple household scissors, why do we still manufacture millions of them? Their role is strictly informational, not defensive.

Plastic seals are molded from polypropylene (PP), a material with low tensile strength designed for "Visual Indication." They function to maintain the chain of custody for empty containers, airline trolleys, or low-risk domestic hops where theft is not the primary concern.

The "Chain of Custody" Logic

A plastic seal is a label with a tail. It tells you if the door was opened, but it does nothing to stop the door from opening. Its pull-apart strength is typically under 40 kg. I recommend these strictly for "Empty" status indicators. When a trailer returns to the depot empty, a plastic seal confirms that no one has tossed contraband inside during the return trip.

The Misuse Trap

The biggest danger is using these for loaded trailers. I have seen companies secure electronics with a fixed-length plastic seal because "it's cheaper." This is dangerous. A plastic seal can be heated and melted back together, or simply ripped off and replaced if the thief has a similar-looking seal. There is no physical defense capability. Use them for inventory control, inner drum liners, or verifying that a cleaned tank hasn't been contaminated. Never use them to protect value.

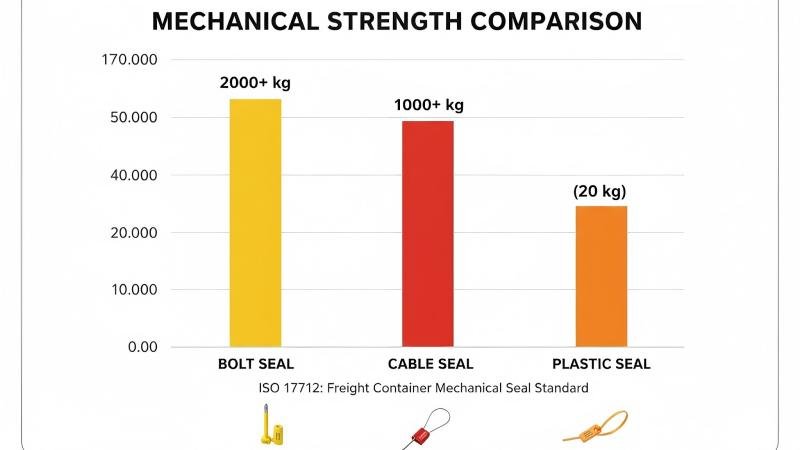

Direct Comparison: Tamper Resistance Levels Across Material Types?

To make an informed purchasing decision, you need to see the raw data. The manufacturing specifications reveal the massive gap in protection capability between these three categories.

The following table compares the Physical Defense, Tensile Strength, and Best Application for each seal type, establishing a clear hierarchy of security performance.

Material Performance Hierarchy

Here is the engineering breakdown of what you are actually buying:

| Seal Type | Material Composition | Approx. Tensile Strength | ISO 17712 Rating | Primary Function |

|---|---|---|---|---|

| Bolt Seal | Hardened Carbon Steel + ABS | > 1,000 kg | High Security (H) | Physical Lock & C-TPAT Compliance |

| Cable Seal (3.5mm) | Galvanized Braided Steel | > 1,000 kg | High Security (H) | Adaptable Lock for Deformed Latches |

| Cable Seal (1.5mm) | Galvanized Braided Steel | > 300 kg | Security (S) | Securing Valves & Drums |

| Plastic Seal | Polypropylene (PP) | < 40 kg | Indicative (I) | Visual Check / Empty Status |

Deciphering the Data

The data shows a clear divide. Bolt and heavy Cable seals are in the "Defense" category. They require tools to remove. Plastic seals are in the "Administration" category. They require only intent to remove. When you select a seal, you are selecting a position on this force-resistance curve. A security manager must match the tensile strength of the seal to the potential value loss of the cargo.

How to Balance Security Budgets with Cargo Protection?

Every purchaser wants to save money, but saving $0.50 on a seal to lose a $100,000 shipment is poor math. How do you allocate your budget efficiently?

A strategic budget balances the cost of the seal against the "Risk Profile" of the route and cargo. Use expensive High Security seals for long-haul, high-value trips, and low-cost Indicative seals for short-haul, empty returns.

The "Cost vs. Loss" Equation

I advise clients to categorize their endpoints. For a cross-border shipment prone to organized hijacking, the price of a High-Security Bolt Seal (let's say $0.50 - $1.00) is negligible insurance. The "physical defense" it provides buys time—and time is the enemy of theft.

Optimization Strategy

However, you waste money if you put a Bolt Seal on a tote box of office supplies moving between floors. Here is my "Smart Tiering" strategy:

- High Value / International: Use Bolt Seals. The cost is mandatory for compliance and physical security.

- Irregular Hardware / Tankers: Use Cable Seals. You pay slightly more for the flexibility, but you ensure the seal actually fits.

- Empty Returns / Inter-Depot: Use Plastic Seals. Here, you are just verifying the asset hasn't been used. You can save 80% of your budget here to reinvest in better seals for the high-risk routes. This is how you maximize protection without inflating the procurement budget.

Conclusion

The hierarchy is dictated by physics: Bolt seals are rigid fortresses for high-risk cargo, Cable seals offer steel-strength flexibility for difficult latches, and Plastic seals are visual indicators for inventory control.

Fortify Your Supply Chain with ProtegoSeal

Don't secure a fortress with a piece of plastic. At ProtegoSeal, we manufacture seals that meet the strictest ISO 17712 standards. Whether you need the shearing resistance of a bolt or the flexibility of a cable, we have the manufacturing expertise to secure your load. Contact us today for a consultation on matching the right seal to your specific fleet requirements.