Your cargo is worth thousands, even millions. Yet, it's locked in a simple steel box crossing the ocean, vulnerable to theft, tampering, and contamination. A single weak link in your process can lead to catastrophic losses.

The solution isn't just a better lock; it's a systematic, end-to-end security process. True container security relies on a series of verified checks, from the container's structural integrity to the documented application of a high-security seal, forming an unbroken "Chain of Integrity."

True container security is an unbroken "Chain of Integrity." In my 15+ years in this industry, the costliest mistakes I've seen didn't happen because of a faulty seal. They happened because a high-security seal—the strongest link—was placed on a chain with rusty, broken links elsewhere. A $10 bolt seal is useless if there's a hole in the container wall or if the sealing process itself is flawed. This guide is the exact process I walk my clients through, link by link, to forge a truly secure supply chain.

Is Your Container Structurally Sound? The Pre-Loading Inspection Checklist

You found a container, and it looks fine from a distance. But are you sure it's a secure steel box and not a collection of hidden vulnerabilities?

A compromised container structure makes any high-security seal worthless. Before loading, you must perform a thorough inspection to ensure the container itself isn't the weakest link in your security chain. A proper check involves more than a quick glance.

In my early days as a QC inspector, I learned this lesson the hard way. A client lost a shipment of electronics, yet their expensive bolt seal was intact. The thieves had simply pushed through a poorly repaired patch on the container wall. That expensive lesson is why the "box" itself is always the first link to check. This isn't just about looking for obvious holes; it's a systematic process known as the 11-point inspection.

The Essential 11-Point Container Inspection

Before a single item is loaded, your team on the ground should verify these points:

| Area | Key Inspection Point | What to Look For |

|---|---|---|

| Walls (Interior) | Are there any patches, non-standard repairs, or dents? | Mismatched paint, recent welding, or light showing through. |

| Walls (Exterior) | Check for protrusions or unusual structural elements. | Fake panels or hidden compartments. |

| Floor | Is the flooring uniform and solid? Does it seem unusually thick? | A false floor or loose boards. |

| Ceiling/Roof | Inspect from the inside and outside for patches or damage. | Cracks, rust, or signs of repair. |

| Doors (Interior) | Are the locking bars and mechanisms secure and operational from the inside? | Bypassed mechanics or damaged locking rods. |

| Doors (Exterior) | Do they close tightly and flush? | Gaps, bent hinges, or difficulty closing. |

| Locking Mechanisms | Are the handles, hasps, and retainers free of tampering? | New welds, tool marks, or excessive rust. |

| Vents | Are vent covers secure and not tampered with? | Loosened bolts or damaged mesh. |

| Beams & Supports | Check all structural beams for integrity. | Bends, cracks, or signs of stress. |

| Container Number | Does the number match your shipping documents? | Altered or painted-over numbers. |

| Light Test | Close both doors and stand inside. Is any light visible? (aka "Flashlight Test") | Any pinpoint of light indicates a hole or gap. |

This inspection must be a non-negotiable part of your SOP (Standard Operating Procedure).

Are You Using the Right Seal? A Guide to ISO 17712 and C-TPAT Compliance in 2025?

Your container is sound. You grab a seal and lock it. But is that seal just a plastic tag, or is it a recognized barrier to entry that customs officials will trust?

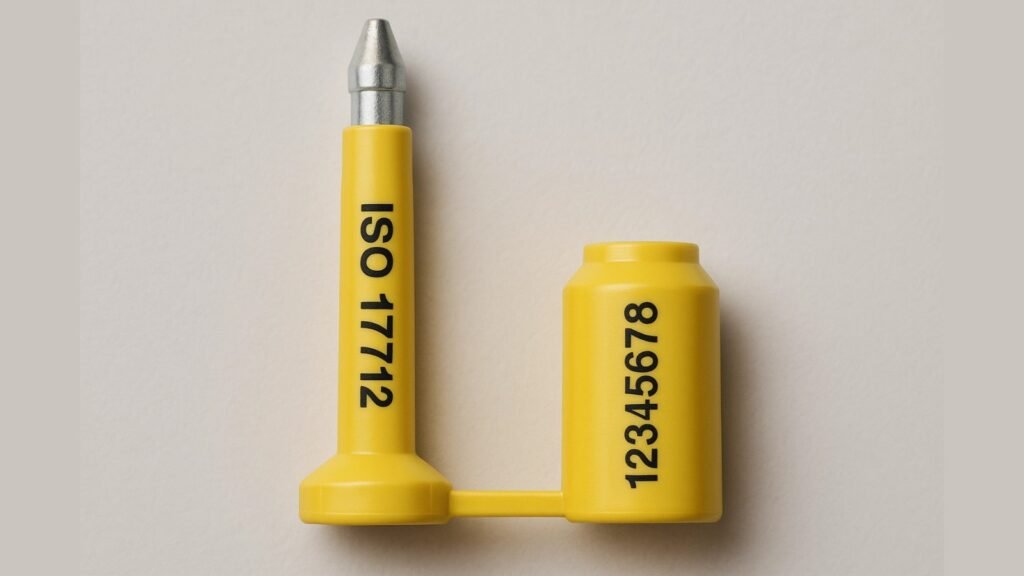

Using a non-compliant seal is like locking your house with a paperclip. For true security and frictionless customs clearance, you must use a High Security Seal that meets ISO 17712:2013 standards. This is a mandatory requirement for secure trade programs like C-TPAT.

Selling security seals means I have to be an expert in these global regulations. The "H" classification for High Security is not a marketing term. It means the seal has been independently tested by an ISO 17025 accredited lab to withstand specific shearing, tensile, and impact forces. In 2025, customs authorities are stricter than ever. If your container arrives with a flimsy, uncertified seal, it's a major red flag for inspection, causing costly delays. This seal is the strongest link in your chain, so its quality is paramount.

Understanding ISO 17712 Classifications

- "I" for Indicative Seals: Simple plastic or thin cable seals. They only show if tampering has occurred and offer no physical barrier.

- "S" for Security Seals: More robust than indicative seals, offering a limited physical barrier.

- "H" for High Security Seals: The gold standard. This includes bolt seals and thick cable seals (1/8-inch or 3.5mm+). They require specialized tools like bolt cutters for removal and are mandatory for C-TPAT shipments.

Always demand a certificate from your supplier confirming their seals meet both Clause 5 (physical testing) and Clause 6 (security-related practices).

How Can a Documented Sealing Process Prevent Insider Threats and Errors?

You have a sound container and the right seal. But who puts it on, and how? An undocumented process creates gaps for costly mistakes and, worse, internal theft.

A documented sealing process, often called the “VVTT Procedure,” forges a strong link of accountability. It requires staff to Verify, View, Tug, and Twist the seal, then record the details, creating a clear chain of custody.

The biggest operational headaches I help clients solve are often related to human error. A seal number is written down incorrectly. A seal isn't clicked in place and falls off in transit. A documented process mitigates this. I once worked with a large retailer whose shrinkage from one distribution center was cut by over 30% simply by enforcing a strict VVTT process with photos. It eliminates plausible deniability; someone is always accountable.

The VVTT Sealing Protocol

- V - View: A designated loader and a witness (e.g., driver) view the seal together.

- V - Verify: They verify the container number and seal number match the shipping documents before application.

- T - Tug: After applying the seal, they physically tug on it hard to ensure it is properly locked.

- T - Twist: They then twist and turn the seal to confirm it doesn't rattle or come apart.

- Record & Photograph: The seal number is recorded and signed off in a log and on the Bill of Lading. A clear photo of the locked seal is taken as final proof.

What Does a Layered Security Strategy Look Like in 2025?

You've sealed the container door, but modern thieves are sophisticated. Is a single bolt seal enough to protect high-value cargo like electronics or pharmaceuticals?

In 2025, a single seal is just one part of a layered security strategy. This means combining the high-security seal with other technologies like barrier locks and GPS trackers to create multiple obstacles that increase the time and effort needed to breach the container.

The goal of a layered approach is to buy time and create evidence. A criminal might be able to cut one bolt seal in 30 seconds. But can they also cut a hardened steel barrier lock and disable a GPS tracker before an alert is sent? Probably not. I advise my clients with high-value goods that the extra $100 - $200 spent on layered security is the cheapest insurance they can buy against a six-figure loss. It adds more strong links to the chain.

Components of a Modern Layered Strategy

- Primary Seal: An ISO 17712 "H" class bolt or cable seal on the door hasp. This is the non-negotiable baseline.

- Barrier Seal/Lock: A heavy-duty lock that clamps across the container's locking bars. It requires power tools and significant time to defeat.

- GPS/IoT Device: A covert tracker providing real-time location and alerts for unauthorized door openings or route deviations.

- Tamper-Evident Labels: Used to seal individual pallets inside, proving if cargo was disturbed even if the main door seal is intact.

Your Container Arrived: What Are the Key Steps to Verify Its Integrity?

Your container has finally arrived. The journey is over, but the final link in your security chain—verification—is still waiting to be forged.

At the destination, you must inspect the container and the seal before breaking it. This closing of the security loop involves verifying the seal and container numbers against your documentation to ensure what you sealed is what you received.

This final check is where the entire chain of integrity is proven. A client once called me in a panic; their container arrived, but the seal number was different. They immediately followed their protocol and refused the container. It turned out the shipment had been breached and a fraudulent seal applied. Their rigorous receiving protocol prevented them from unknowingly accepting a container full of worthless goods.

The 5-Step Receiving Protocol:

- Verify Container Number: Before anything else, check that the physical container number matches your Bill of Lading.

- Verify Seal Number: Carefully check the seal's serial number. Does it exactly match the number recorded at the origin, with no discrepancies?

- Inspect the Seal: Is the seal intact? Look for signs of tampering, like glue, tool marks, or mismatched parts. A genuine seal should show wear consistent with its journey.

- Photograph Evidence: Take a clear photo of the intact seal on the container before removal. This is crucial proof if a claim needs to be filed.

- Document Removal: After verification, cut the seal with proper tools (e.g., 36" bolt cutters). Record the date, time, and personnel who opened the container.

Conclusion

A secure supply chain depends on a rigorous, consistent process that forms an unbroken "Chain of Integrity." By treating container security as an end-to-end checklist, from structural inspection to final verification, you build a truly resilient defense.

Forge Your "Chain of Integrity" with an Expert

Feeling overwhelmed by ISO standards and security protocols? You don't have to be. At ProtegoSeal, we provide more than just seals; we provide the expertise to help you forge every link in your security chain. We can help you build a robust, compliant, and cost-effective security process. Contact us for a consultation.