Thinking the only risk in cutting a high-security seal is a slip of the cutters? This mistake can cause serious personal injury, damage cargo upon opening, or even invalidate your entire shipment legally, leading to huge financial losses.

The safest method is a complete safety protocol built on three pillars: Personal Safety (protecting you), Product Safety (protecting the goods), and Process Safety (protecting your business). This protocol turns a simple action into a controlled, professional procedure.

In my 20-year career, I've seen that true "safety" is an entire system. Newcomers only worry about the moment of the cut. But professionals understand safety as a structure with three pillars: Personal Safety (protecting the operator), Product Safety (protecting the cargo), and Process Safety (protecting the legal and commercial interests). These are equally vital. Any method that ignores one is not safe. This isn't about one action; it's about a complete "Safety Protocol" you must follow every time. This guide is that protocol.

Why Must You Verify a Seal's ID Before Ever Touching a Cutter?

You're in a rush to unload, so you grab the cutters and snip the seal to get the doors open. What could possibly go wrong?

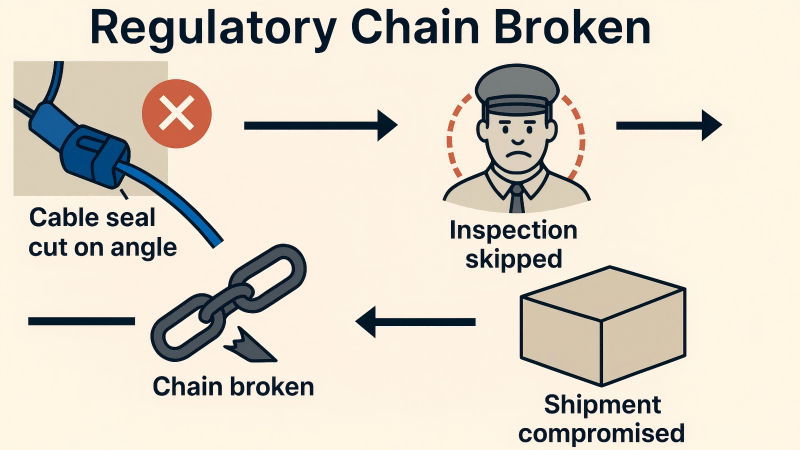

Later, an auditor finds the seal number doesn't match the manifest. Because you've already cut the seal, you have zero proof the cargo wasn't tampered with. This is a catastrophic failure of Process Safety.

This is the most critical and most often-skipped step. A high-security seal is not just a lock; it is a legal instrument. Its unique serial number is the final link in the Chain of Custody, proving the cargo arrived as it was sent. Cutting the seal before verification is like shredding a contract before you've read it—the evidence is gone forever. This single mistake can lead to rejected shipments, insurance claim denials, and severe legal liabilities. The “cut” is the last thing you do, not the first. Professionals know the camera on their phone is a more important first tool than the cutter.

The Verification Protocol (Process Safety)

- Locate: Find the seal number on your Bill of Lading, manifest, or shipping app.

- Inspect: Examine the physical seal for any signs of tampering (scratches, glue, mismatched parts).

- Photograph: Take a clear, close-up photo of the intact seal, ensuring the number is legible.

- Verify: Match the number on the seal to the number in your documentation.

- Record: If all is correct, log the time, date, and your name as the person verifying. If it does not match, STOP. Do not cut the seal and immediately follow your company’s exception protocol.

What Safety Gear and Workspace Prep Are Non-Negotiable?

It’s just one quick snip, so you decide to skip the safety glasses and gloves. You’ve done it a hundred times without a problem.

This complacency is how accidents happen. When a high-tensile steel cable is cut under pressure, it can release metal fragments at high velocity. This is a direct threat to your Personal Safety, and it's completely avoidable.

Protecting yourself is not optional. The forces involved in cutting a high-security seal are significant. A 3.5mm or 5mm seal is designed to resist cutting, meaning you must apply immense force. When it finally gives way, the release of energy is sudden.

Non-Negotiable Safety Checklist (Personal Safety)

- Eye Protection: Always wear ANSI-rated safety glasses with side shields. A fragment of steel in the eye is a life-altering injury.

- Hand Protection: Wear thick leather or cut-resistant gloves. The cut edges of the seal are dagger-sharp, and cutters can slip.

- Stable Footing: Ensure you are standing on dry, level ground. Never stand on a wet or unstable surface, or on a ladder.

- Clear Workspace: Remove all obstacles and personnel from the immediate area, especially from the swing path of the container doors.

This preparation takes less than 60 seconds and prevents 99% of all physical injuries related to seal removal.

How Do You Perform the Cut to Prevent Both Injury and Cargo Damage?

You've done the prep work. Now you just need to snip the cable as fast as possible, right?

No. An uncontrolled cut can still lead to injury or damage. If a seal is cut carelessly, the heavy container door can swing open unexpectedly, either striking you or allowing unsecured cargo to fall out. This is where Personal Safety and Product Safety intersect.

The cut itself must be a controlled, deliberate action. The goal is to sever the cable cleanly while maintaining control of both the tool and the container door. Use a high-quality, professional-grade bolt cutter of at least 24 inches (600mm) for proper leverage.

The Professional Cutting Technique (Personal & Product Safety)

- Grip the Seal: With your gloved hand, hold the body of the seal firmly. This prevents it from flying off when cut.

- Position the Cutter: Place the cutter jaws as close to the locking body as possible for a clean cut. Ensure your knuckles and fingers are clear.

- Position Your Body: Stand to the side of the container door latch, never directly in front of the doors. This keeps you out of the swing path.

- Execute the Cut: Apply steady, even pressure. Do not use a jerky, wrenching motion. The cut should be a smooth "squeeze."

- Control the Doors: Brace yourself for the doors to shift. Be prepared to control the door opening, preventing it from swinging open violently.

What Overlooked and Hidden Risks Can Improper Removal Trigger?

The seal is cut, the doors are open. The job is done, right?

Not yet. The cut seal itself now becomes a hazard. A discarded piece of sharp steel cable left on the ground is a puncture risk for tires and a trip or cut hazard for personnel. This is an often-overlooked aspect of Personal Safety.

Beyond the physical risks, there are hidden process risks as well. Forgetting to retain the cut seal can cause problems later. Some internal audits or insurance claims may require the physical seal as corroborating evidence.

Post-Removal Risk Mitigation (Personal & Process Safety)

- Immediate Disposal: Immediately collect both pieces of the cut seal. Do not leave them on the ground or in the container.

- Designated Scrap Bin: Place the sharp metal pieces in a designated metal scrap bin. This prevents injuries and tire damage.

- Retention Protocol: Check if your company policy requires you to retain the cut seal. If so, place it in an evidence bag, label it with the date, time, and manifest number, and store it securely.

A professional finishes the job completely, and that includes cleaning up the hazards they create.

How Does an Unprofessional Removal Process Invalidate the Chain of Custody?

So you skipped a few steps. The cargo got delivered. What's the real harm?

The real harm comes when something goes wrong. If the recipient claims items are missing or if illicit goods are found, the first thing investigators will scrutinize is the supply chain security records. Your sloppy removal process has just created a giant, un-defendable hole in that record.

The Process Safety you protect is your company's legal defense. A documented, professional seal management protocol is your proof that you acted responsibly. Skipping steps implies that your entire operation might be careless.

| Professional Protocol (Defensible) | Unprofessional Process (Indefensible) |

|---|---|

| Seal number photographed & verified before cut. | Seal cut immediately upon arrival. |

| Cut is documented by a trained operator. | Anyone with cutters can remove the seal. |

| Cut seal is retained as evidence per policy. | Seal is lost or discarded on-site. |

| A complete log exists from origin to destination. | "We don't know" is the answer to auditors. |

When you face a multi-million dollar lawsuit over a compromised shipment, your "defensible" record is worth far more than the few minutes you saved by taking shortcuts. Every step in the protocol is a link in a legal chain armor for your business.

Conclusion

The safest way to remove a cable seal is not a single action but a complete protocol. By embracing the three pillars—Personal, Product, and Process Safety—you protect yourself, your cargo, and your company from harm and liability.

Implement a Professional Seal Safety Protocol Today

Don't wait for an accident or a lawsuit to expose flaws in your process. At ProtegoSeal, we provide the tools and expertise to build a complete safety protocol for your supply chain. Contact us to ensure every seal removal is safe, secure, and professionally documented.