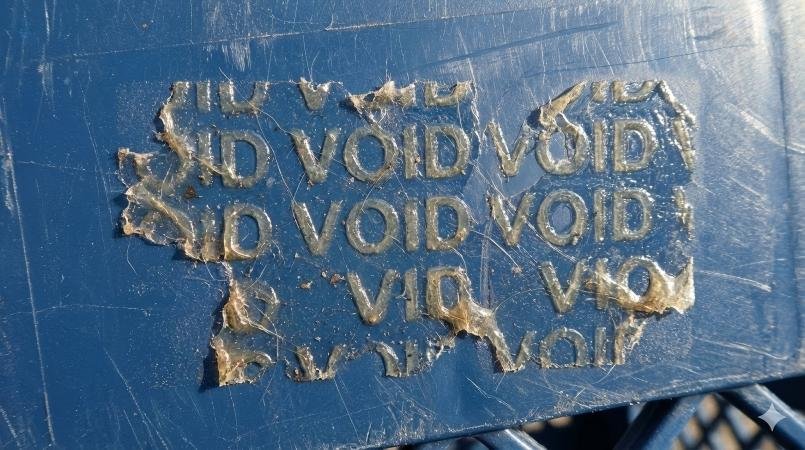

Are your warehouse crates covering in sticky, ugly "VOID" residue? Trying to scrape off old security labels by hand is a time-wasting nightmare that damages your expensive logistic assets.

To remove security stickers in under 5 minutes, you must stop scraping. The proven method combines thermal softening with a chemical soak. Use a heat gun to relax the adhesive first. Then, apply a limonene-based solvent to dissolve the bond safely without damaging the plastic surface.

I have watched countless warehouse staff struggle with scrapers. They spend twenty minutes on a single box only to leave it looking worse than before. This inefficiency kills your turnover speed. By understanding the chemistry of the glue, we can turn a twenty-minute struggle into a five-minute process.

Why Are Security Stickers Harder to Remove Than Standard Labels?

Do you wonder why a shipping label peels off significantly easier than a security seal? The answer lies in the intentional engineering designed to create a permanent bond.

Security stickers use aggressive acrylic adhesives designed for "substrate tear." Unlike standard labels meant to stay whole, security labels function differently. They are chemically formulated to fracture. If removed, they leave a permanent "VOID" message behind. This residue is a feature, not a bug.

The Engineering of Frustration

To solve the cleaning problem, you must respect the opponent. Standard logistical labels use rubber-based adhesives. They hold the paper but release cleanly. Security labels are the opposite. They utilize high-tack acrylic adhesives. These adhesives cure and harden upon contact with oxygen.

Key Differences in Adhesion

Here is why your fingernail test fails on security labels but works on shipping labels:

- Total Transfer Design: The label has multiple layers. The bottom layer separates from the top. When you pull, the top lifts, but the "VOID" message is supposed to stay stuck.

- Oxidation Hardening: Unlike rubber glues that dry out, acrylics get harder as they age. A six-month-old sticker is twice as hard to remove as a new one.

- Substrate Bonding: The adhesive flows into the texture of the plastic crate. It creates a mechanical lock, not just a surface stick.

What Solvents Effectively Dissolve the Stubborn "VOID" Residue?

Is water and soap useless against this residue? You need a chemical agent capable of breaking the molecular chain of the acrylic polymer without melting your plastic crate.

Water cannot tackle hydrophobic acrylics. The most effective solvents are Limonene (Citrus-based) and Isopropyl Alcohol (99%). These agents penetrate the adhesive matrix. They cause the hardened glue to swell and turn into a wipeable gel.

The Chemistry of Dissolution

I have seen operators ruin expensive polycarbonate containers by using acetone. While acetone dissolves glue, it also dissolves the plastic box itself. The surface becomes cloudy and brittle. You must use a solvent that targets the adhesive specifically. Based on my testing, D-Limonene is the champion. It is found in citrus peels and acts as a solvent for resins. It chemically breaks the chain of the "VOID" message.

Solvent Selection Guide

Choosing the right liquid is the difference between a clean box and a ruined one.

| Solvent Type | Effectiveness | Safety for Plastic Boxes | Best Used For |

|---|---|---|---|

| Citrus (Limonene) | High | Excellent | Heavy, thick sticky residue. |

| Isopropyl Alcohol (99%) | Medium | Excellent | Light cleaning and final finish. |

| Acetone / Thinner | High | Dangerous | Do not use. Will melt plastic. |

| Soapy Water | Zero | Excellent | Dust only, useless for glue. |

Heat vs. Scraping: Which Method Best Protects the Container Surface?

Does your team reach for a metal scraper the moment they see a barcode? This instinct causes permanent damage that ruins the future usability of the container.

Physical scraping creates micro-scratches that trap dirt. The superior method is thermal softening. Using a heat gun relaxes the adhesive's grip. This allows you to peel the bulk of the label off gently before cleaning the rest.

The Science of Thermal Softening

Adhesives have a specific temperature range where they change state. They transition from a hard solid to a soft gum. This is simple physics. By applying controlled heat using a heat gun, you raise the adhesive temperature. This happens above its glass transition point. The bond "relaxes." You can then lift 90% of the glue off with the label, rather than leaving it on the box.

The Hidden Cost of Mechanical Scraping

I strictly advise against using metal scrapers or razor blades.

- Surface Gouging: Scraping creates deep scratches in the plastic.

- Adhesion Failure: These scratches act like "canyons." When you apply a new seal next month, air pockets in these scratches prevent full contact.

- Security Risk: A new seal applied to a scraped surface falls off easily during transit. This creates a false security alert.

- Hygiene Issues: Scratches trap dirt and bacteria. This is a major compliance issue for food or pharma crates.

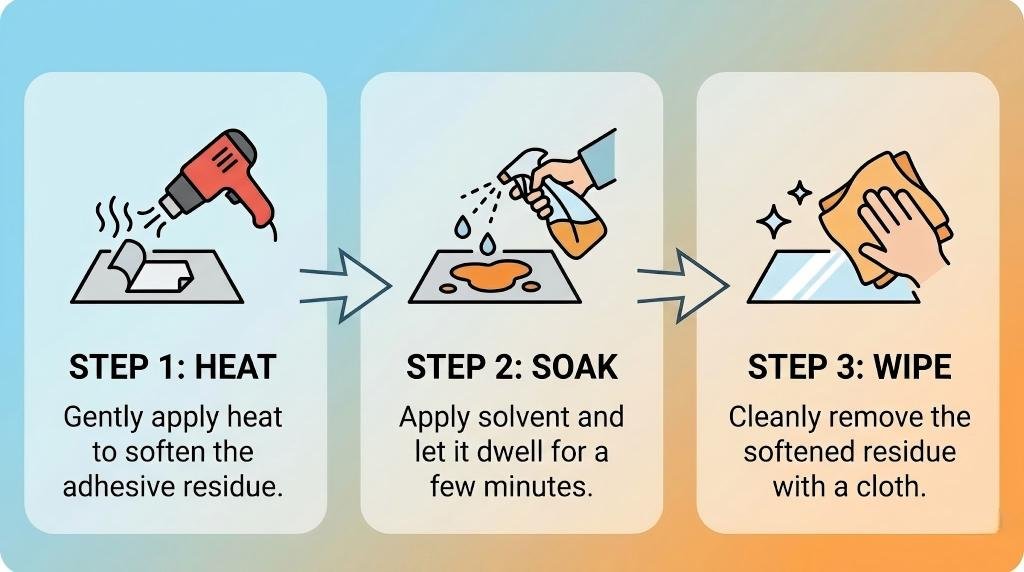

The 3-Step Cleaning Protocol: Peel, Soak, and Wipe

Do you want a standardized process that any employee can follow? This simple three-step protocol ensures consistency and speed. It removes the guesswork from container preparation.

The "Peel, Soak, Wipe" protocol is the industry standard for efficiency. First, heat and peel the bulk label material. Second, soak the remaining "VOID" message in solvent for 60 seconds. Finally, wipe clean with a microfiber cloth.

A Standard Operating Procedure (SOP)

To get the cleaning time under 5 minutes, follow this strict sequence. Do not skip the "Soak" step. Patience here saves scrubbing later.

- Thermal Peel (30 Seconds): Aim a heat gun at the label. Move it back and forth; do not hold it in one spot. Once the label is hot to the touch, lift the corner with your fingernail. Pull slowly at a 45-degree angle. Remove as much material as possible.

- Chemical Soak (60 Seconds): You will see the "VOID" pattern left behind. Spray your citrus solvent or IPA directly onto it. Stop. Do not wipe immediately. Let the chemical sit for one full minute. It needs time to penetrate and swell the hardened acrylic.

- The Wipe Down (30 Seconds): After the soak, use a microfiber cloth. The residue should turn into a soft gel. It wipes away easily. Apply firm pressure. If spots remain, spray again and wipe.

A Smarter Alternative: Switching to Non-Transfer Labels for Frequent Reuse

Is cleaning taking up more labor hours than the shipping itself? If you reuse containers daily, the best cleaning method is to eliminate the need for cleaning altogether.

For high-frequency logistics, switching to Non-Transfer Security Labels is the ultimate efficiency hack. These labels reveal a "VOID" message on the label itself when peeled. They leave zero residue on the container, completely eliminating the cleaning step.

The Zero-Residue Technology

If your business model involves "Returnable Transport Items" (RTIs), residue labels are a bottleneck. Non-Transfer Labels (often called Non-Residue labels) utilize a different layer mechanics. The "VOID" message is printed on a dry-peel layer. It sits between the adhesive and the face stock.

ROI Analysis: Why Pay More to Save More?

Although a non-transfer label costs slightly more per unit, the operational savings are massive. You eliminate the cost of solvents, scrapers, and most importantly—labor time.

| Cost Factor | Standard Residue Label | Non-Transfer (Zero Residue) Label |

|---|---|---|

| Label Cost | Low | Medium |

| Cleaning Labor | 5 Minutes per box | 0 Minutes |

| Consumables | Solvents & Rags required | None |

| Container Life | Short (damaged by scraping) | Long (no damage) |

| Total Cost/Trip | Higher (due to labor) | Lower (due to speed) |

Conclusion

Cleaning security residue requires "thermal softening" and chemical action, not brute force. By using heat and solvents—or upgrading to non-transfer labels—you protect your assets and prepare containers in minutes.

Optimize Your Turnaround with ProtegoSeal

Stop wasting hours scraping sticky clean messy residue. At ProtegoSeal, we offer premium Non-Transfer Security Labels specifically designed for reusable logistics containers. Our labels provide maximum security with zero cleanup required. Contact us today to request a free sample kit and test the "peel-and-go" difference for yourself.