Your rail shipments are part of a massive, booming network, making them more vulnerable to theft and tampering than ever. A single compromised container can mean huge losses, customer disputes, and a damaged reputation, but how do you secure assets across thousands of miles of track?

The global railroad boom, projected to hit $781.2 billion by 2030, is massively increasing freight volumes. This directly drives demand for high-strength cable seals, which provide C-TPAT compliant security to provide physical evidence of tampering for shipping containers and railcars, ensuring cargo integrity across long supply chains.

I just read a fascinating industry report predicting massive growth in the global railroad market. But as someone who has spent over a decade focused on asset security, I don't just see bigger numbers; I see bigger risks. The expansion of rail networks means more goods are traveling further and passing through more hands, creating more opportunities for tampering and theft. This report confirms a trend I've been seeing with my clients: the growth in rail is directly tied to a growing demand for robust, reliable security. Let’s break down exactly what this means for security on the ground.

How Does the Growth in Rail Freight Directly Impact Security Needs?

Your cargo is just one of millions of containers moving on the rails. With rail freight projected to grow at a 4.5% CAGR, relying on old, weak seals is like putting a flimsy lock on a bank vault, inviting trouble.

This explosion in volume directly increases the need for high-strength, barrier-class seals. Cable seals are essential for securing high-value goods, preventing pilferage, and maintaining a secure chain of custody from origin to destination, a non-negotiable in today's logistics environment.

The report highlights that rail freight is booming because it's a cost-effective and sustainable solution to highway congestion. For a procurement manager or logistics director, this means more of your company's assets will be sitting on railcars. My experience has shown that when container volume increases, so does opportunistic theft. A weak seal can be cut, tampered with, and sometimes even replaced without leaving obvious evidence. This is where high-strength cable seals become critical.

Why Cable Seals Are the Solution

High-strength cable seals are classified as "barrier seals" for a reason. They provide a physical deterrent that requires specialized tools, like bolt cutters, to remove. This simple fact elevates them far above simple plastic indicative seals.

| Feature of Cable Seals | Security Benefit for Rail Freight |

|---|---|

| Braided Steel Cable | Resists cutting with simple tools, forcing thieves to use heavy-duty cutters which causes a delay and attracts attention. |

| ISO 17712 "H" Classification | Meets the standard for High-Security Seals, a requirement for international shipping and C-TPAT compliance. |

| Laser-Engraved Serial Numbers | Provides a unique identifier that cannot be easily altered, ensuring a verifiable audit trail. |

In short, the more valuable your cargo and the longer its journey on the rails, the more essential a barrier seal becomes.

Why Does Cross-Border Trade Make High-Security Seals Non-Negotiable?

Your shipment is crossing three borders on its way to the customer. Each border crossing and intermodal transfer is a weak point in your supply chain, creating a security blind spot where liability is unclear.

As global trade expands, high-security seals are non-negotiable. They act as a universally understood signal of integrity, simplifying inspections and providing clear evidence if a container is breached between transfer points.

One of the biggest pain points for my clients is assigning liability. If a container arrives with missing goods, who is responsible? The report notes impressive growth forecasts for China and a massive market in the U.S., highlighting the importance of transcontinental trade. This is where a robust sealing protocol is invaluable.

The Role of Seals in Establishing Accountability

A high-security cable seal creates a clear point of responsibility.

- Origin: The seal is applied and its unique number is recorded on the bill of lading. The container is now secure.

- Transfers: At each handover point (e.g., from port to rail yard), the seal's integrity is checked. If the seal is intact, the new carrier accepts responsibility.

- Destination: The consignee verifies the seal number matches the documentation before breaking it.

This simple, physical process provides a powerful legal and operational tool. It replaces ambiguity with certainty. The market's growth, especially in major trading blocs like the US ($115.8 Billion) and China (projected $132.2 Billion), is built on this kind of secure, verifiable logistics.

How Do Seals Protect High-Value Railway Assets Themselves?

You're focused on the cargo, but what about the trains? New technologies like electrification and high-speed rail, as mentioned in the report, mean the railcars and infrastructure are more valuable and complex than ever.

High-strength cable seals aren't just for containers. They are also used to secure sensitive compartments on locomotives, signal boxes along the track, and maintenance equipment. This prevents unauthorized access, vandalism, and theft of critical, high-value components.

When I talk with clients in the rail industry, we often discuss securing more than just the payload. Modern locomotives are packed with expensive electronics and copper wiring—prime targets for theft. The report's focus on "greener technologies such as electrification" points to this trend accelerating. A broken-down train due to a stolen part can halt an entire line, costing thousands of dollars per hour in delays.

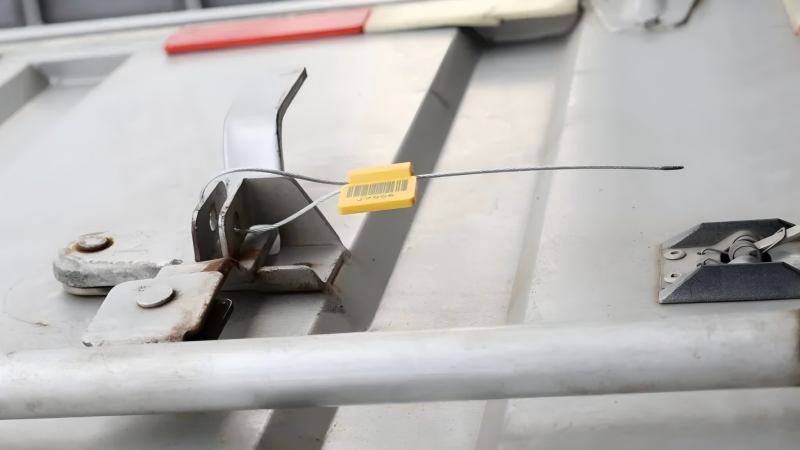

We use adjustable cable seals for these applications. Unlike fixed-length bolt seals, their variable-length cable can be cinched tight on various access panels, cabinets, and equipment levers. This prevents casual tampering and ensures that only authorized maintenance personnel, who have the authority and tools to cut the seal, can gain access. It's a simple, cost-effective way to protect multi-million dollar assets.

How Do Modern Seals Integrate with Digital Tracking Systems?

You track your shipments with GPS and RFID, but this digital data can't prove if a door was physically opened. You're left with a digital "ping" but no physical proof of tampering, creating a critical security gap.

Modern cable seals close this gap by integrating with digital systems. Seals with barcodes or QR codes link the physical seal to the digital manifest. This allows drivers and yard staff to scan the seal with a smartphone, instantly verifying its number against a central database and time-stamping the inspection.

The report highlights the "integration of digital technologies, including the Internet of Things (IoT)." This is where I see the most exciting evolution in security. A physical seal is no longer just a dumb piece of metal. It's the physical anchor for a digital system. Think of it this way:

- GPS/IoT tells you WHERE the container is.

- The cable seal tells you IF the container is secure.

When a driver scans a QR-coded seal upon arrival, the system can automatically update the status to "Arrived - Seal Intact." If they arrive and the seal is broken, they can take a picture and upload it directly into the system, creating an immediate, geolocated, time-stamped incident report. This provides a complete security picture, satisfying the need for both a robust physical barrier and the data-rich environment that modern logistics demands.

What Features Should You Look For in a Rail-Specific Cable Seal?

You know you need cable seals, but the market is flooded with options. Choosing a sub-par seal that fails under stress or doesn't meet compliance standards is just as bad as using no seal at all.

For rail applications, you must choose a seal that is at least 3.5mm in diameter and ISO 17712:2013 "H"-certified. It should have a non-preformed steel cable that splays upon cutting and a body made of durable aluminum alloy to withstand harsh weather and yard conditions.

After inspecting thousands of seals in my QC days and solving client problems in sales, I've learned that not all cable seals are created equal, especially for the high-stakes rail environment. Here is my checklist for procurement managers.

My Go-To Checklist for Rail Cable Seals:

- ISO 17712:2013 "H" Certification: This is non-negotiable. It certifies the seal as a high-security barrier. You can read the standard's scope here.

- Cable Diameter and Type: For railcars, I recommend a minimum of 3.5mm. Crucially, the cable must be non-preformed, meaning it unravels when cut, making re-sealing impossible.

- Durable Body Construction: Look for anodized aluminum. Plastic bodies can become brittle in extreme cold and are not suitable for the physical abuse of a rail yard.

- Permanent Markings: Serial numbers and logos must be laser-engraved, not just printed. Laser engraving physically etches the marking into the metal.

- Tamper-Evident Locking: The internal locking mechanism should be designed to show clear signs of tampering if someone tries to pick or disable it.

Choosing a seal with these features ensures you are deploying a true security device, not just security theater.

Conclusion

The railroad industry's impressive growth is creating more opportunities but also more security risks. High-strength cable seals are essential tools for protecting assets, ensuring cargo integrity, and providing the clear evidence needed in today's complex global supply chain.

Secure Your Rail Cargo with ProtegoSeal's Proven Solutions

Don't let your cargo become another statistic in transit theft. As rail volumes increase, so should your security measures. At ProtegoSeal, we provide ISO 17712 compliant high-strength cable seals designed for the demands of the railroad industry. Contact us to secure your supply chain today.