Choosing the wrong plastic seal seems like a small detail, but this mistake routinely leads to cargo theft, contamination, and costly shipment rejections. This single decision quietly exposes your entire supply chain to catastrophic financial and reputational damage.

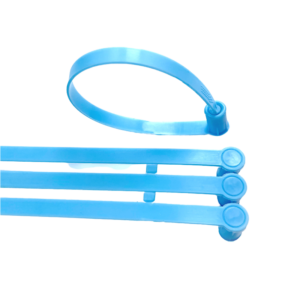

The key difference lies in their design, material, and intended security level. Plastic seals are differentiated by their locking mechanism (variable vs. fixed length), tensile strength, and innate tamper-evident features. Each type is engineered for a specific risk scenario, not as a one-size-fits-all solution.

In my years managing asset protection programs, I've seen companies make costly mistakes by treating all plastic seals as interchangeable commodities. I learned that the real questions sit behind this simple decision. The key isn't just to pick a "type," but to match the seal's design to a specific, real-world risk.

How Do Locking Mechanisms and Materials Define the Seal's Role?

You see a simple plastic strip, but a thief sees an opportunity. Assuming all seals offer the same protection is the most common mistake I encounter, leaving assets exposed to opportunistic tampering and theft.

Plastic seals are primarily defined by their locking mechanism (variable vs. fixed length), material composition (e.g., polypropylene vs. nylon), and structural additions like metal inserts. Each design provides a specific level of tamper evidence and breaking strength, aligning with classifications for indicative seals under international frameworks like the ISO 17712 standard.

Dive Deeper: From Indicative Function to Barrier Function

Fundamentally, a plastic seal is "indicative"—it's not designed to be an unbreakable barrier like a bolt seal. Its main job is to show clear, unambiguous evidence if someone has tried to gain access. The security is in its ability to reveal tampering, not necessarily prevent it entirely.

I saw this principle in action during a project for a major e-commerce retailer battling returns fraud. Customers were purchasing high-end apparel, wearing it, and then returning it for a full refund. The company was losing thousands. Their existing process used no seals.

My solution was to introduce a uniquely numbered, variable-length plastic seal. The process was simple but effective:

- Before shipping, a seal was applied through the garment label and a visible tag.

- It was pulled tight, leaving only a small, non-intrusive loop.

- The returns policy was updated: "Returns are only accepted if this security seal is intact and untampered."

This small operational change made it impossible to "wear and return" without breaking the seal. The result was a nearly 70% reduction in returns fraud within the first quarter. This project taught me a crucial lesson: the "right" seal is the one that directly counters a specific human behavior or vulnerability.

Here’s a practical breakdown I use to classify the main types:

| Seal Category | Primary Use Case | Key Characteristic | My Project Example |

|---|---|---|---|

| Variable-Length | Bags, sacks, fire extinguishers, roll cages | Pull-tight mechanism for a snug, adjustable fit. Highly versatile. | Securing cash-in-transit bags where any slack is a security risk. |

| Fixed-Length | Truck doors, shipping containers, totes | Single locking position with a consistent loop size. Provides clear evidence. | Sealing totes of lab samples to ensure a verifiable chain of custody. |

| Padlock Seals | Airline carts, utility meters, emergency kits | Clicks shut like a padlock. Easy for one-handed use on small hasps. | Locking in-flight service trolleys for a regional airline. |

| Meter Seals | Electric, water, and gas utility meters | Usually a two-part system with a wire. Designed to prevent utility fraud. | A utility client needed to stop meter bypassing that cost over $200,000 annually. |

Material matters. Polypropylene (PP) offers a great balance of flexibility and cost. However, for applications requiring higher heat resistance or durability in cold weather, Nylon is a far superior, albeit more expensive, choice.

Is the Most Common Logistics Seal Always Your Best Choice?

Logistics managers often default to variable-length seals for their versatility. But I've learned that this one-size-fits-all approach can introduce silent vulnerabilities, creating what I call an "illusion of security" where a seal is present but ineffective.

While variable-length (pull-tight) seals are the most common in logistics due to their flexibility, they are only effective when applied correctly. They are perfect for mail sacks, but for trailer doors or containers needing a consistent, verifiable closure, a fixed-length seal often provides better, more unambiguous tamper evidence.

Dive Deeper: Application Defines Security

A pull-tight seal applied too loosely to a trailer door is almost useless. It can often be manipulated or bypassed without breaking it. I learned this the hard way on a beverage distribution project. Drivers were using pull-tight seals but leaving several inches of slack. This allowed for quick tampering at truck stops, leading to a consistent loss of over $10,000 per month in pilfered goods.

My initial thought was to retrain drivers. But human error is a constant. The better solution was to change the tool itself.

My revised approach:

- Switch the entire fleet to fixed-length seals. The length was standardized for their specific truck latches.

- The application process became foolproof: thread the seal and push until it makes a loud, satisfying "click."

- The consistent loop size and audible confirmation created a simple, binary check for integrity that anyone—from the driver to the warehouse receiver—could verify at a glance.

This move required more upfront planning but it virtually eliminated in-transit pilferage on that route. This aligns with principles from industry bodies like the Council of Supply Chain Management Professionals (CSCMP), where procedural simplicity is a cornerstone of effective security.

When Is It Time to Upgrade to a Wire-Reinforced Seal?

You're stuck. A standard plastic indicative seal isn't enough, but a high-security bolt seal is overkill. Ignoring this middle ground means you're either accepting unnecessary risk or wasting money on over-securitization.

You should upgrade to a security seal with a wire component when you need a significant step up in breaking strength without the cost and tooling required for a bolt seal. These seals are ideal for high-value shipments, securing industrial equipment, or any situation where the seal might face significant physical stress during transit.

Dive Deeper: My Checklist for Upgrading Seal Strength

A wire-reinforced seal is a specific tool for a specific job. In one project securing high-value electronics, my client was using heavy-duty plastic seals. They suffered a series of targeted attacks where seals were simply snapped off with brute force. Their losses were exceeding $50,000 per incident.

Switching to a high-security bolt seal was an option, but it meant equipping every receiving dock with bolt cutters and creating new procedures. The operational overhead was too high. Instead, I introduced a plastic-body seal with a 1.5mm braided steel wire. This small change was transformative. The wire was too strong to be broken by hand and required a dedicated cutter to defeat—a tool far less common than pliers. This elevated the effort just enough to deter opportunistic thieves.

Here is the simple checklist I now use with clients to decide if an upgrade to a wire seal is justified:

- Is the asset value significant? If a single loss event exceeds a predefined threshold (e.g., $1,000), a stronger seal is warranted.

- Is the route high-risk? Does the shipment pass through areas known for cargo theft? You can identify these by leveraging data from industry reports, like those from the Transported Asset Protection Association (TAPA).

- Have you found evidence of prior tampering? If your team is finding stretched, glued, or heat-manipulated plastic seals, it's a clear signal to escalate security.

- Is the seal exposed to physical stress? For securing equipment or tarps that flap in the wind, a standard plastic seal can fail. A wire seal's durability is far superior.

If the answer to two or more of these is "yes," a wire-reinforced seal is my standard recommendation.

How Does Customization Go Beyond Just a Logo?

Many clients think customizing a seal is about picking a color and adding their logo. This view is dangerously simplistic. True customization embeds security and operational data onto the seal, transforming it from a passive tag into an active component of your tracking system.

Effective customization begins with defining security level, application environment, and tracking needs. This process determines the seal type, material, and unique identifiers like laser-engraved serial numbers or QR codes. These features turn the seal into a unique data point in your supply chain, not just a piece of plastic.

Dive Deeper: My Framework for Strategic Seal Customization

In a project for a pharmaceutical distributor, we moved far beyond basic aesthetics. The client was concerned about counterfeit drugs entering their supply chain and also needed to verify cold chain integrity.

My framework for them involved a multi-layered customization process:

- Security Level Definition: The high value of the product demanded a seal that showed clear evidence of tampering. We chose a fixed-length seal with a metal locking clip insert, making it significantly harder to defeat.

- Environmental Assessment: The seals had to withstand refrigerated transport. We specified nylon material instead of polypropylene, as nylon stays ductile at lower temperatures where other plastics can become brittle—a well-documented principle in polymer science.

- Data and Tracking Integration: This was the critical step.

- Unique Serial Numbers: For basic chain-of-custody.

- 2D Barcodes (Data Matrix): These were encoded with the serial number, batch number, and expiration date. Warehouse staff could scan the seal upon arrival to instantly verify the shipment's contents against the manifest in their ERP. This helps meet traceability requirements from bodies like the FDA.

- Thermochromic Ink: We added a small, printed spot on the seal that permanently changed color if the shipment's temperature exceeded a critical threshold. This provided an immediate visual cue of a potential cold chain breach.

This level of customization turned a simple plastic seal into a powerful tool for ensuring product integrity, security, and regulatory compliance.

Which Plastic Seal Type Is Actually the Safest?

I'm often asked, "What is the single safest plastic seal?" This question, while well-intentioned, is flawed. It’s like asking a mechanic for the "best" tool. The best tool depends entirely on the job.

The "safest" plastic seal is the one whose design and material properties are perfectly matched to the specific risks of your application. While a wire-reinforced seal offers the highest tensile strength, it may be the wrong choice for a first-aid kit, where a low-break-strength padlock seal is superior because it allows for quick emergency access.

Dive Deeper: Context Defines Security, Not Just Strength

Security is not an absolute; it's a measure of resistance against a specific threat. A high-security meter seal is designed to prevent utility fraud and may require several minutes and specific tools to remove—making it "safe" in that context. But using that same seal on a fire extinguisher would be dangerously unsafe, as it would delay access in an emergency.

My process rejects the idea of a single "safest" seal and instead uses a risk-based model. Here’s how I frame the decision for my clients:

| If your primary risk is... | Then your "safest" seal is one that... | Example Seal Type |

|---|---|---|

| Opportunistic, low-level theft | Is inexpensive, easy to apply, and provides immediate visual evidence of being opened. | Standard Pull-Tight Seal |

| Unauthorized access to controlled items | Can be applied and removed quickly, but clearly breaks upon opening. | Padlock Seal |

| Covert tampering or substitution | Includes unique, laser-engraved identifiers (barcodes, serials) that are difficult to replicate. | Any type with advanced customization |

| Brute-force attacks or physical stress | Has a reinforced structure, like a metal wire, offering high tensile strength. | Wire-Reinforced Seal |

The safest choice is never just about physical strength. It's about a holistic strategy where the seal, your procedures, and your team's training all work together to mitigate your most probable threats.

Conclusion

Choosing a plastic seal is a critical risk management decision, not a simple purchase. A strategic approach focuses on the specific application, risk level, and operational reality to provide genuine security.

How ProtegoSeal Can Fit Into Your Next Seal Program Decision

Navigating the nuances of tensile strength, tamper evidence, and operational fit is a complex task. I've seen firsthand how a well-chosen seal program can protect a company from significant loss, while a poor choice creates constant, costly problems.

If you are struggling to define the risks in your supply chain or need to develop a comprehensive security protocol, the expert team at ProtegoSeal can help. We go beyond just selling products; we partner with you to analyze your specific challenges and design an integrated solution. For a detailed consultation to match the right seal to your application, please contact us.