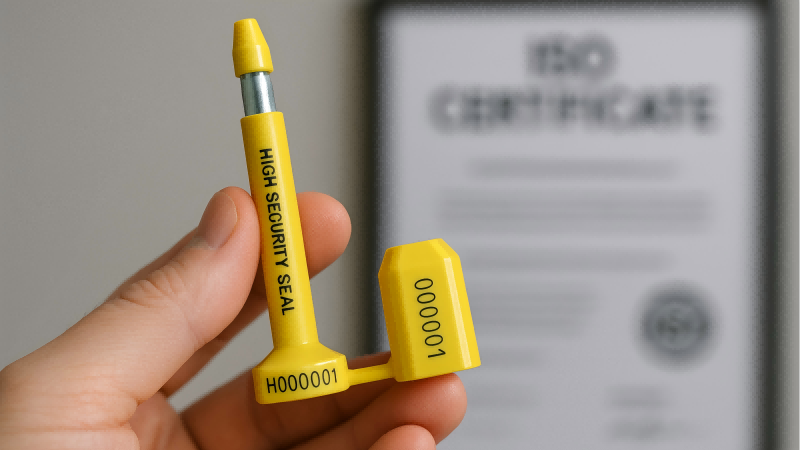

You've been told to buy "ISO 17712 compliant" high-security seals. A supplier sends you a certificate that looks official, but a nagging doubt remains. How do you know it's genuine? A fake seal could get your container impounded by customs, leading to massive delays and financial losses.

True verification is a three-dimensional process. You must scrutinize the paper certificate, interrogate the supplier's security processes, and physically examine the seal itself. Only when all three pieces align can you be confident in their compliance.

Most buyers make a fatal mistake: they treat the ISO 17712 certificate as a finish line. They get the paper, check the name, and assume the job is done. I've learned from 15 years in this business that the certificate is only the starting line. Verifying compliance is like detective work. It's a diagnosis of a supplier’s "operational DNA." This guide is my personal checklist for conducting that investigation.

ISO 17712 Clause 5 vs. Clause 6: Why Is This Distinction Critical for Buyers?

You have a certificate that says "ISO 17712 compliant." But are you aware that this phrase can be dangerously misleading?

The critical distinction is between Clause 5 and Clause 6. A seal compliant only with Clause 5 has passed physical strength tests but lacks audited security protocols in its manufacturing. For true supply chain security and C-TPAT compliance, you absolutely need Clause 6.

This is the most important—and most often missed—detail on a certificate. Think of it this way:

- Clause 5 - Physical Strength: This clause tests the seal's physical toughness. Can it withstand minimum forces for tensile, shear, and impact? This earns the "H" for High Security rating. It proves the lock is strong.

- Clause 6 - Security-Related Practices: This clause requires an independent audit of the manufacturer's own security processes. Are they tracking every serial number? Is access to tooling controlled? Do they have documented procedures to prevent unauthorized production runs? This proves the key maker is trustworthy.

A professional supplier must be compliant with both. A supplier who only emphasizes their seal's physical strength (Clause 5) while avoiding questions about their internal security (Clause 6) is a major risk.

The Paper Trail: A Step-by-Step Guide to Verifying an ISO Certificate?

The supplier sent you a PDF of their certificate. How do you confirm that this "paper evidence" is legitimate and not just a clever forgery?

You must independently verify the document's authenticity. This involves scrutinizing the testing lab's accreditation, contacting the lab dir2025-11-03 16:43:11 Mondayectly, and cross-referencing every detail on the certificate with the actual product you intend to buy.

Treat the certificate like a legal document. Here is my three-step verification process for this "paper evidence":

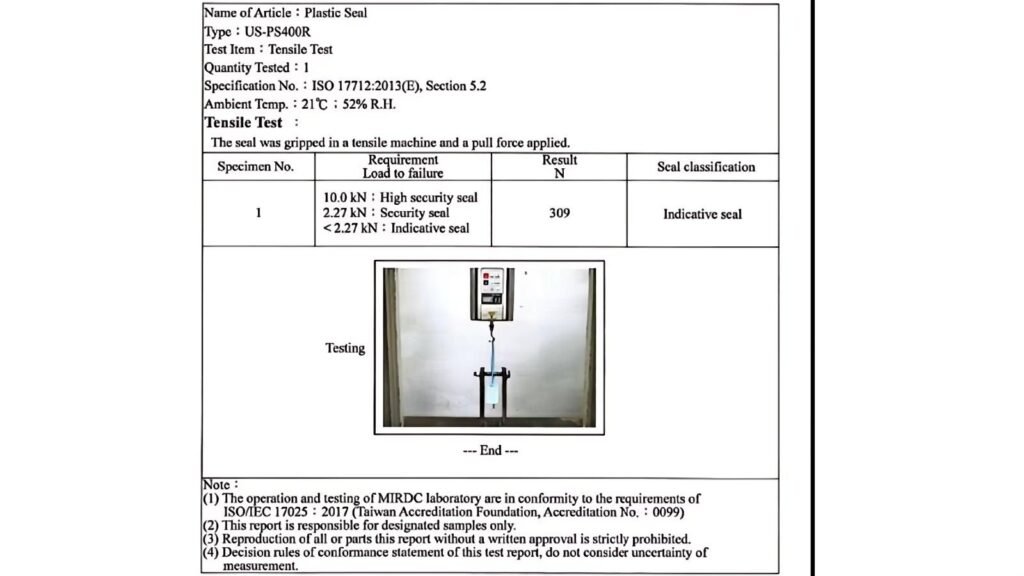

- Check the Lab's Credentials: Look for the name of the testing laboratory on the certificate. This lab must be accredited to ISO/IEC 17025 (General requirements for the competence of testing and calibration laboratories). A quick search for the lab's name plus "ISO 17025 accreditation" should confirm this. If the lab isn't accredited, the test results are not considered valid under the standard.

- Contact the Lab Directly: Do not rely on the PDF alone. Find the laboratory's official website (do not use contact info from the certificate itself) and email them. Ask them to confirm the validity of the certificate number for the supplier in question. This single step foils almost all fraudulent certificates.

- Cross-Reference the Details: Does the certificate list the exact seal model number you are purchasing? A certificate is issued for specific models. A supplier might have a valid certificate for one seal, but try to pass off a different, non-compliant model as being covered. Check the issue and expiration dates.

Beyond the Certificate: Questions to Ask About a Supplier's Manufacturing Process?

The paper trail checks out. Now you need to collect "oral testimony." How can you probe a supplier's operations to see if their claimed compliance is real?

Ask pointed questions about their security procedures. A truly compliant manufacturer will have immediate, detailed answers. A supplier who is merely "paper compliant" will give vague, evasive responses.

This is where you diagnose their "operational DNA." Here are the questions I always ask:

- "Can you describe your process for ensuring serial number uniqueness and preventing duplicates across your entire production history?" (A good answer involves a centralized, access-controlled database, not just an Excel sheet.)

- "What are your physical and digital access controls for the tooling and dies used to make our high-security seals?" (Look for answers about locked storage, authorized personnel lists, and production logs.)

- "What is your documented procedure for the destruction of rejected, defective, or overrun seals?" (A professional supplier has a shredding/granulating process that is witnessed and logged, to prevent these seals from entering the grey market.)

- "Can you provide a C-TPAT seal compliance letter?" (This is a letter where they formally state their compliance, adding a layer of legal accountability.)

Their ability to answer these questions confidently and with detail is a far better indicator of compliance than the certificate alone.

Warning Signs: 5 Red Flags That Your Supplier Might Not Be Genuinely Compliant?

You're in discussions with a potential supplier. What are the subtle clues that suggest their compliance claims might not be trustworthy?

Look for inconsistencies between their price, promises, and paperwork. Warning signs include abnormally low prices, an unwillingness to answer detailed questions, or offering certificates that are vague, expired, or issued by a non-accredited lab.

Having vetted dozens of suppliers over the years, I've learned that certain patterns emerge. Be extremely cautious if you see any of these:

- The Price is Too Good to Be True: Manufacturing a truly compliant high-security seal costs money (quality steel, audited processes, R&D). If a supplier's price is 50% lower than established competitors, they are almost certainly cutting corners on material quality or security protocols.

- Evasive Answers: When you ask the tough questions from the previous section, they respond with "Don't worry, we are compliant" or change the subject.

- Generic or Expired Certificates: They provide a certificate that doesn't list a specific seal model, or one that expired six months ago.

- No Trace of a Testing Lab: The certificate lists a testing lab that has no website or contact information, or one that is not ISO 17025 accredited.

- Refusal to Provide Samples for Your Own Testing: A confident, compliant manufacturer is proud of their product and will happily provide samples. A supplier who hesitates is hiding something.

Can You Spot the Difference? Physical Characteristics of a Truly High-Security Seal

You have the "paper evidence" and "oral testimony." Now for the final step: examining the "physical evidence." What should you look for in the seal itself?

A genuinely compliant high-security seal has distinct physical traits. These include high-quality, traceable markings, robust construction, and anti-spin features that are clearly visible and functional. A cheap knockoff will have flimsy markings and design flaws.

As a former QC Inspector, this is my favorite part. Get samples and check these things yourself:

- Markings: Are the name/logo and serial number laser-etched and clear, or are they poorly printed and easy to smudge? Laser marking is harder to tamper with.

- Serial Numbers: Do the bolt and the pin have the same matching serial number? This is a fundamental requirement.

- Anti-Spin Mechanism: On a bolt seal, there should be a locking mechanism (often a square or hexagonal shape) that prevents the pin from being spun out with a drill (a "spin attack"). Test it. When locked, can you spin the pin freely? You shouldn't be able to.

- Materials and Build: Does the seal feel substantial? The bolt shaft should be solid steel. The plastic coating should be thick and fully encase the metal components. If you see exposed, low-quality metal or thin plastic, it's a red flag.

- Engagement "Click": When you lock the seal, there should be a solid, audible "click" that confirms the locking mechanism has engaged.

Conclusion

Verifying ISO 17712 compliance is not a simple checkbox; it's a critical investigation. By conducting a "Three-Dimensional Cross-Validation" of the paper, the process, and the product, you can truly vet a supplier and protect your supply chain.

Partner with a Verifiably Compliant Manufacturer

This process might seem daunting, but it's second nature to a true security partner. At ProtegoSeal, we welcome the tough questions because our processes and products are built on a foundation of verifiable compliance. Contact us to experience the confidence that comes from working with a transparent, professional, and genuinely compliant manufacturer.