When a client asks me how to choose a cable seal for maximum security, I tell them they’re on the right track, but we need to redefine the question. The real question isn't "Which seal is the strongest?" but rather, "What is my specific security threat?"

Maximum security doesn't come from buying the "strongest" seal; it comes from making the "most matched" choice. The selection process is a Threat Diagnosis. You must first evaluate your adversary and environment, and only then choose your weapon. An unmatched choice, whether too strong or too weak, is a failed security strategy.

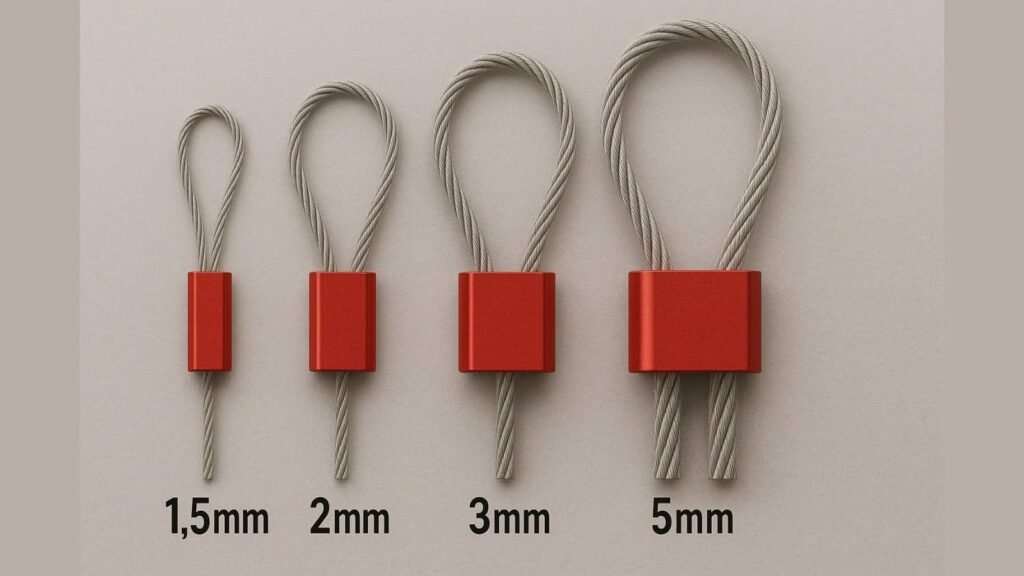

I see people get stuck on cable diameter, thinking a 5mm cable is always better than a 3.5mm one. But a thick cable with a weak lock is useless, as is a high-end seal used incorrectly. My job isn’t to sell you steel wire; it’s to help you diagnose your risks and build a security solution that perfectly matches them.

Cable Diameter and Length: How to Balance Security with Application Flexibility?

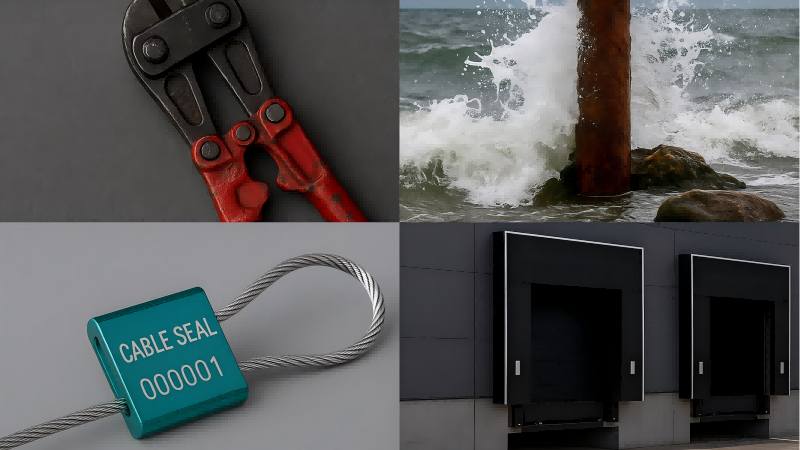

The first step in your Threat Diagnosis is to assess the force and environment. Is your primary threat a casual thief with pliers, or a determined attacker with professional bolt cutters?

You diagnose the threat level to determine the cable diameter, and you diagnose the physical environment to determine the length. For high-security shipments, an ISO 17712 compliant seal with at least a 3.5mm diameter isn't a choice; it's the mandatory starting point.

Let’s diagnose this methodically.

Step 1: Diagnose the Brute Force Threat (Diameter)

Your threat level dictates the cable's required resistance to cutting.

- Low Threat (Indicative): Your goal is simple tamper-evidence (e.g., first-aid kits, utility meters). 1.5mm - 2.5mm cables are sufficient. They won't stop a determined attacker but will clearly show that a seal has been broken.

- High Threat (Barrier): Your goal is to resist a physical attack for a period of time (e.g., cross-border shipments, high-value goods). Here, you need a high-security "H" class seal, typically with a 3.5mm or thicker, non-preformed steel cable to meet standards like C-TPAT.

Step 2: Diagnose the Physical Environment (Length)

Length has nothing to do with strength; it's about a proper fit.

- The Problem with Mismatch: A cable that is too short is unusable. A cable that is too long creates a loose loop—a major vulnerability that a thief can exploit without even breaking the seal.

- The Diagnosis: Before you order, measure what you need to secure. Is it a truck door latch or a large, complex valve? Choose the length that allows you to pull the seal completely tight.

Does the Lock Body Material Matter? Aluminum, Zinc, or Steel?

Your diagnosis has identified the right cable. But what about the lock body protecting the mechanism?

Yes, the material is critical. Your diagnosis must include the threat of impact or manipulation. A thick cable is useless if the lock body shatters with a hammer blow or corrodes in a harsh environment.

As a former QC Inspector, I've seen countless locks fail under stress tests. The body's job is to shield the internal locking clutch. Here's how to match the material to the threat:

| Threat Diagnosis | Recommended Material | Rationale |

|---|---|---|

| Tamper-Evidence in a Controlled Environment (e.g., indoor logistics) | Aluminum | Lightweight and ideal for clear laser marking. The threat of physical impact is low. |

| General Outdoor Use with Moderate Risk (e.g., domestic freight) | Zinc Alloy | A good balance of hardness and cost-effectiveness. Resists moderate impacts. |

| High-Impact or Corrosive Environments (e.g., maritime, heavy industry) | Steel | Maximum resistance to crushing, cutting, and severe physical attacks. |

Choosing steel for a low-risk indoor tote is over-engineering and wasted budget. Choosing aluminum for a sea container is a critical failure in your threat diagnosis.

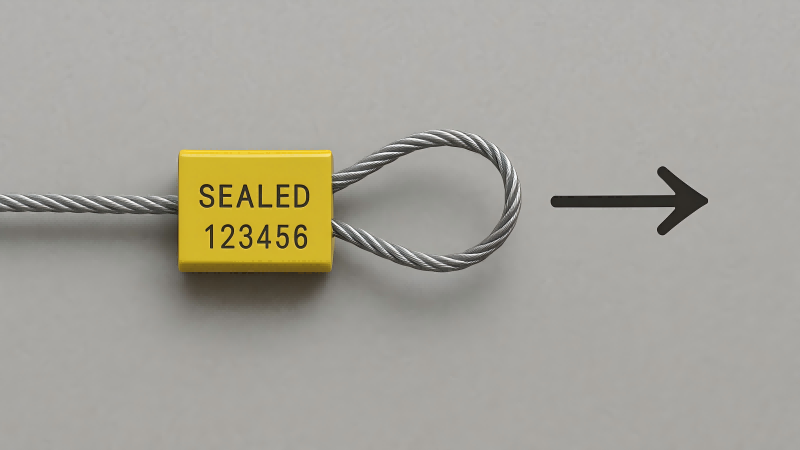

Is Your Cable Seal Truly Locked? The One Critical Check You Must Perform.

You’ve completed your diagnosis and selected the perfect seal. But a diagnosis is useless without a proper procedure.

To confirm your locking mechanism is engaged, you must perform a "pull-back" test. After pulling the cable tight, give the cable end a sharp tug away from the lock. If it’s truly locked, it will not move.

This is the final, practical step of your security application. I have seen seals that looked secure but could be slid open because the internal ball bearings never engaged. This is a complete failure of the security system.

- Insert & Cinch: Thread the cable and pull it tight.

- Verify: Yank the cable backward.

- Confirm or Replace: If it doesn't move, you are secure. If it gives way even slightly, the seal is faulty. Cut it off immediately, document the failure, and use a new seal. This check verifies that your entire "locking solution" is active.

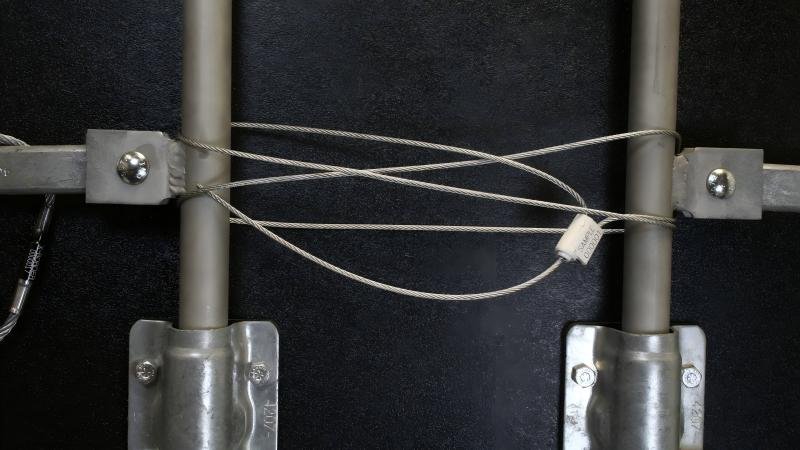

How Should the Cable Be Looped and Pulled for Maximum Security?

A verified lock is great, but is the application itself secure?

The cable must be pulled as tight as possible, leaving zero slack. Any extra loop is a vulnerability you are handing to a thief. A tight seal immobilizes the hardware; a loose seal merely decorates it.

Think of it this way: a loose cable fails to account for a manipulation threat. I've consulted on cases where thieves cut the hasp—not the seal—slipped it out of a loose cable loop, emptied the container, and then put the broken hasp back in the loop. The seal was intact, but the cargo was gone. An absolute disaster that could have been prevented.

- The Rule: Pull the cable hand-tight until it is completely taut.

- The Test: You should not be able to fit a finger or a tool inside any loop.

Beyond Containers: What Other Assets Can a Cable Seal Protect?

Does this "Threat Diagnosis" methodology only apply to containers?

No. This method is universal. The flexibility of a cable seal makes it the perfect tool for diagnosing and securing almost any asset that lacks a standard locking point.

The diagnosis process works for any asset.

- Asset: Rail car tanker valve. Threat: Unauthorized operation. Diagnosis: Need for a lockout-tagout device. Solution: A mid-range cable seal wrapped tightly around the valve handle.

- Asset: High-value air cargo cage. Threat: Theft during transit. Diagnosis: Need for a high-security, tamper-evident barrier. Solution: A 3.5mm ISO-compliant cable seal on the latches.

- Asset: In-plant chemical totes. Threat: Contamination or unauthorized access. Diagnosis: Need for clear tamper-evidence. Solution: A brightly colored, uniquely numbered 2.5mm cable seal.

The principle is the same: diagnose the threat, match the solution.

Conclusion

True security is not about buying the "strongest" cable seal. It's about performing an accurate Threat Diagnosis to select the solution that perfectly matches your specific risk. By analyzing the threat, environment, and application, you create a complete and effective security system.

Get an Expert Diagnosis for Your Security Needs

Stop guessing and start diagnosing. A mismatched seal is a liability. At ProtegoSeal, we help you analyze your specific threats to create a risk-matched security solution that works. Contact us for a professional security consultation.