You've invested in high-quality hologram stickers to protect your brand, but they're peeling, bubbling, or crooked. This not only looks unprofessional but creates a massive weak point in your anti-counterfeiting strategy.

Applying hologram stickers flawlessly requires a precise, five-step method: Start by meticulously preparing the surface, carefully peel the sticker, position it precisely, apply even pressure from the center out, and finish with a detailed edge inspection. This ensures a permanent bond and activates its full security potential.

When I first started in quality control, I saw companies spend thousands on advanced holograms, only to have their own staff apply them so poorly that they could be peeled off with a fingernail. That's when I realized the truth: applying a hologram sticker is not a decorative task. It is the final, critical step in a technical security deployment. A perfectly applied sticker is an active security feature; a poorly applied one is just a shiny decoration that counterfeiters will easily bypass. This guide will walk you through that professional process.

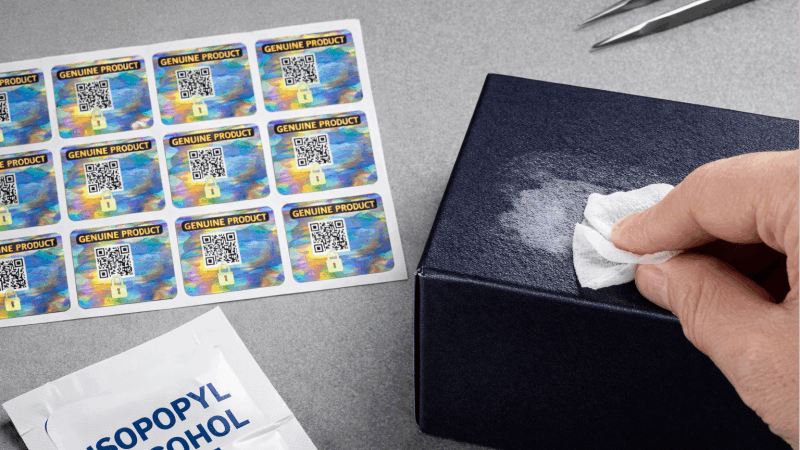

Step 1: Assemble Your Hologram Stickers & Prepare the Surface

You're in a hurry and start slapping stickers on products straight out of the box. A week later, you notice the edges are lifting because of a nearly invisible layer of dust.

Get started by gathering your hologram stickers and the items for application. The most crucial part is to meticulously clean the surface with an isopropyl alcohol wipe or a lint-free cloth to remove all dust, grease, and moisture. A perfectly clean, dry surface is non-negotiable for a permanent bond.

This preparation phase is what separates a professional security application from amateurish sticking. The adhesive on the back of a hologram sticker is engineered to form a powerful, permanent bond, but it can only do so if it makes direct contact with the product surface. Any contaminant, no matter how small, acts as a barrier that drastically weakens the bond.

Why Cleaning is Non-Negotiable

The ability of an adhesive to stick is related to a concept called surface energy. High surface energy means the adhesive can spread out and "grip" the surface effectively. Contaminants like dust, oil from fingerprints, or residual moisture lower this energy and lead to adhesive failure.

Recommended Surfaces and Preparation

| Surface Type | Is it Suitable? | Preparation Method |

|---|---|---|

| Glass, Metal, Hard Plastics | Ideal | Clean with Isopropyl alcohol, dry completely. |

| Coated Paper/Cardboard | Good | Wipe with a dry, lint-free cloth. |

| Porous Wood/Fabric | Poor | Not recommended; adhesive cannot bond evenly. |

| Waxy or Oily Surfaces | No | Adhesive will not stick. |

Taking 30 seconds to clean the surface is the single best investment you can make to ensure the sticker's security features perform for the lifetime of the product.

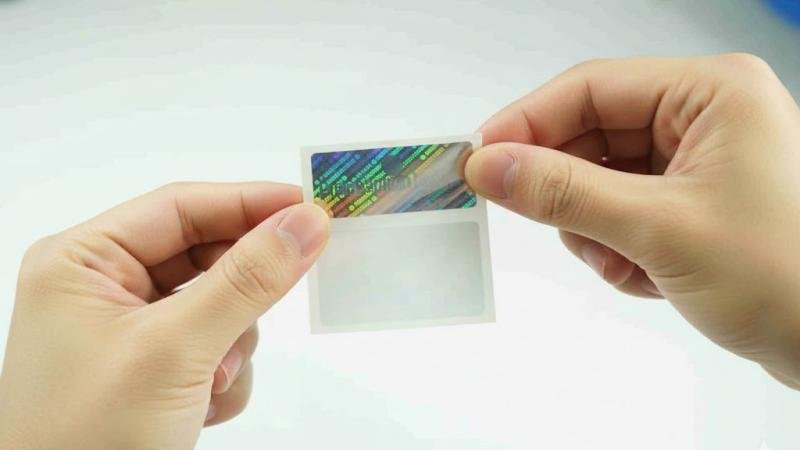

Step 2: Carefully Peel Away the Backing Paper

You quickly rip the sticker off the sheet, your thumb touching the sticky side. You've just contaminated the adhesive, guaranteeing a weaker bond before you even apply it.

Gently fold a corner of the backing paper away from the sticker until an edge of the hologram lifts up. Grip the sticker by its very edges between your thumb and forefinger. Avoid touching the adhesive at all costs, as oils from your skin will compromise its integrity.

I cannot stress this enough: the adhesive is the heart of the sticker's tamper-evident function. Many security holograms are designed with a "void" feature or a fragile, patterned material. This technology depends on a bond that is stronger than the sticker itself, so any attempt to remove it causes the sticker to self-destruct, leaving behind clear evidence of tampering.

The Science of Contamination

Your skin is naturally coated in oils and microscopic particles. When you touch the adhesive, you are essentially creating a non-stick zone. This is a primary cause of adhesive failure. I've seen inspection reports where a perfectly shaped fingerprint was the exact point of failure on a peeled sticker.

Handling Best Practices

- Hold by the Edges: Treat the sticker like a delicate photograph. Never flat-palm it or press your thumb into the middle of the adhesive.

- Minimize Airtime: Once peeled, apply the sticker promptly. Don't wave it around where it can collect airborne dust.

- Use Tweezers (for experts): For very small stickers or high-precision jobs, using a pair of flat-nosed tweezers can be a great way to avoid contact altogether.

Proper handling preserves 100% of the adhesive's engineered bonding power.

Step 3: Precisely Position and Place the Sticker

You try to "eyeball" the placement and the sticker ends up crooked. It looks sloppy and instantly devalues the perceived quality and security of your product.

Position the sticker over the target area without letting it touch down. Use a guiding mark if needed. Anchor one edge of the sticker to the surface first. This "hinge" technique gives you ultimate control for laying the rest of the sticker down perfectly straight.

Consistency is a hallmark of authenticity. When all your products feature a hologram sticker placed in the exact same spot, it creates a powerful brand standard. In my experience, counterfeit products often get this detail wrong. A crooked or randomly placed hologram can be a subtle but immediate red flag for educated consumers and supply chain partners.

Creating a System for Consistency

For applying hundreds or thousands of stickers, freehanding is not an option. You need to create a simple system.

- Create a Jig: If you are applying stickers to boxes, create a simple cardboard or plastic jig. This is a frame with a cut-out where the sticker should go. You place the jig, drop the sticker in, and it's in the perfect spot every time.

- Use Guiding Marks: On your application surface or workbench, use a non-permanent marker or a piece of tape to mark the alignment corners where the product should sit and where the sticker should be applied.

- One Motion Application: Once the leading edge is anchored, use a smooth, single motion to lay the rest of the sticker down. Hesitating mid-application can trap air.

This systematic approach reinforces the idea that you are not just decorating; you are executing a crucial step in your brand protection strategy.

Step 4: Apply Even Pressure to Eliminate Air Bubbles

You've placed the sticker and just press down in the middle with your thumb. This traps small pockets of air, creating ugly bubbles and weak spots in the bond.

Use a plastic squeegee, a credit card, or your thumb covered with a microfiber cloth. Start from the center and press outwards towards the edges with firm, overlapping strokes. This method systematically pushes all trapped air out, ensuring full contact.

An air bubble is more than just a cosmetic flaw; it is a point of zero adhesion. It's an entry point for moisture and a leverage point for anyone trying to peel the sticker off. Eliminating every single bubble is vital for activating the sticker's tamper-evident and security features. A flawless, glass-like finish is the goal.

The Outward Pressure Technique

Imagine you are smoothing a new screen protector onto a smartphone. The principle is identical.

- Center-Out: This is the golden rule. Never start from an edge and press inwards, as this will trap air in the middle.

- Firm, Not Hard: The goal is to apply enough pressure to force the air out and activate the pressure-sensitive adhesive. You don't need to press so hard that you damage the product underneath.

- Overlapping Strokes: Make sure each stroke with your squeegee overlaps the last one by about 25%. This ensures you don't miss any spots and create a uniform bond across the entire surface.

After a few applications, you will develop a feel for the right amount of pressure. The result is a sticker that looks like it's printed directly onto the product.

Step 5: Make a Final Inspection and Secure the Edges

You've applied the sticker and moved on. You didn't realize one corner wasn't fully pressed down. This tiny flaw is now a "start here" invitation for anyone trying to tamper with your product.

Visually inspect the sticker under good light, tilting it to catch reflections. Look for any remaining air bubbles or lifted edges. Run your fingertip firmly around all four edges of the sticker one last time to ensure they are completely sealed against the surface.

This final "edge seal" is your last chance to guarantee the sticker's integrity. The corners and edges are the most vulnerable points. If a bad actor wants to try and remove a sticker, they will almost always start by picking at a corner. A perfectly sealed edge offers no starting point. This minor action can be the difference between a secure product and a compromised one. This process is a fundamental part of a good Quality Management System.

Curing Time

Most pressure-sensitive adhesives continue to strengthen over time, a process called "curing." While the initial bond is strong, the adhesive typically reaches its maximum bonding strength within 24 to 72 hours. Informing your team about this helps prevent accidental peeling or stress on newly applied stickers. For mission-critical applications, letting the products sit for a day before heavy handling is a wise precaution. This final inspection and patience ensures the security deployment is a complete success.

Conclusion

Applying a hologram sticker is a technical security procedure. By following these five steps—prepare, peel, position, press, and inspect—you ensure a flawless application that activates the sticker's full protective power.

Deploy Your Security Strategy with ProtegoSeal

A perfect hologram is only as good as its application. If you need hologram stickers designed for maximum security and ease of use, ProtegoSeal's custom solutions can help. Contact us to design a sticker that protects your brand and empowers your team to apply it perfectly every time.