Ever wonder what goes into making a hologram sticker? Many think it's just shiny printing, completely underestimating its security. The complex industrial process is the real secret behind its power.

Hologram stickers are made through a multi-stage industrial process, not simple printing. It involves optical engineering to create a master, micro-embossing this design onto film, and then finishing with adhesives and printing. This complexity is its core security feature.

Your insight is the key. Early in my career, I visited a hologram production facility for the first time. I expected to see fancy printers. Instead, I saw a cleanroom environment, optical tables stabilized with lasers, and technicians in lab coats. It was more like an advanced physics lab than a print shop. That's when it clicked for me: a hologram's security isn't just in the final product; it's embedded in the monumental difficulty of the process itself. You can't fake it because you can't replicate the industrial chain required to create it.

From Concept to Design: What's the Purpose of Your Hologram Sticker?

A client often says, "I need a hologram sticker." But without a clear goal, the project is already at risk. The most beautiful hologram is useless if it doesn't solve a specific security problem effectively.

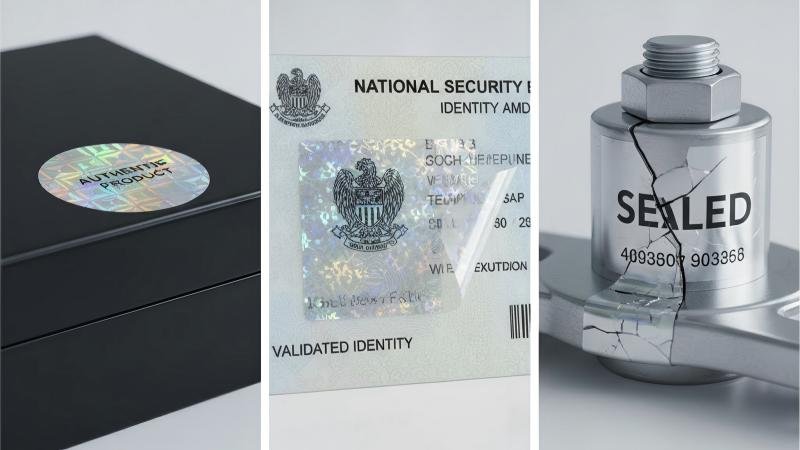

The purpose of your hologram dictates its entire design. Is it for brand protection, quick visual authentication, or as a tamper-evident seal? Answering this question is the first and most critical step in creating a sticker that provides real value.

I always start a client consultation here. The conversation shouldn't be about colors or logos initially. It needs to be about the threat model. What are you trying to stop? Who are you trying to stop? A street-level counterfeiter requires a different level of security than a state-sponsored entity. For example, a simple 2D/3D hologram might be enough to deter casual counterfeiters for a cosmetic product. But for a pharmaceutical product, we need to embed covert features like microtext that require a magnifying glass to see. The design isn't about aesthetics; it's a strategic response to a specific risk.

Defining the Security Goal

The sticker's function is the bedrock of its design. The purpose directly influences the technical specifications.

| Purpose | Key Design Considerations | Example |

|---|---|---|

| Brand Protection | Visually attractive, complex 3D effects, brand logo integration. | A shimmering logo on a high-end electronics box. |

| Authentication | Easy to verify, difficult to copy, kinematic (moving) effects. | A floating eagle on a government-issued ID card. |

| Tamper-Evidence | Frangible material, "VOID" pattern release adhesive. | A seal over a medicine bottle cap that fractures on removal. |

| Track and Trace | Integration of a QR code or serial number with the hologram. | A unique QR code surrounded by a holographic border on a wine bottle. |

The most effective hologram stickers often combine several of these purposes, creating a multi-layered defense.

Preparing for Production: What Artwork is Needed for Your Hologram Sticker?

Once the purpose is clear, we move to the artwork. But this isn't like designing a business card. The artwork for a hologram must be prepared in a specific way that translates into a multi-layered, three-dimensional optical effect.

At a minimum, high-resolution vector files are required. This artwork needs to be separated into different layers, each corresponding to a different depth or visual effect in the final hologram. This is a technical design process, not just a graphic one.

I've had clients send a simple JPEG file and ask, "Can you make this a hologram?" The answer is yes, but it will be a flat, unimpressive one. The magic comes from the separation. We have to deconstruct their 2D logo into a 3D space. I'll explain that we'll put their company name on the back plane, make their logo float in the middle, and have kinetic lines of text move in the foreground. This process requires a designer who understands the language of holography, not just graphic design. They need to think in terms of depth (Z-axis), not just width and height (X and Y-axes).

Artwork Checklist for Hologram Production

To ensure a smooth transition from screen to physical product, the artwork must be impeccable.

- File Format: Vector formats like Adobe Illustrator (.AI) or .EPS are mandatory. They allow for infinite scaling without losing resolution, which is critical for creating the microscopic patterns.

- Layer Separation: The design must be broken into layers. Each layer will be recorded at a different depth or with a different optical effect. A typical separation might include:

- Layer 1: Background (e.g., guilloché patterns)

- Layer 2: Main Subject (e.g., company logo)

- Layer 3: Foreground Elements (e.g., floating text, kinetic effects)

- Color Mode: Artwork should be in grayscale or black and white. The colors in a hologram are created by the diffraction of light, not by ink. The artwork simply defines the structure that creates these colors.

Good preparation at this stage saves weeks of delays and ensures the final hologram is as secure and visually dynamic as intended.

The Heart of the Process: Creating the Hologram Master

This is the step that separates real holography from simple shiny printing. It's where we translate digital artwork into a physical, microscopic landscape on a piece of glass. This is the "industrial chain" link that creates the real security barrier.

Creating the master, or "mastering," is an optical-physical process done in a laboratory environment. Using high-powered lasers, we record the separated artwork layers onto a photosensitive glass plate. Each layer is recorded at a different angle and depth to create the 3D parallax and movement.

This is pure optical engineering. The cost of this equipment runs into the hundreds of thousands, if not millions, of dollars. It requires vibration-dampened tables because a movement of even a fraction of a wavelength of light can ruin the recording. This is not something a counterfeiter can set up in their garage. After the optical recording, the image is developed, and through an electroforming process, we create a nickel shim. This metal shim is the "master plate"—a durable, microscopic inverse of the hologram that will be used for mass production. This mastering process is the heart of the security.

From Light to Metal: The Mastering Steps

- Laser Recording: The multiple 2D artwork layers are recorded one by one onto the photosensitive plate using a split-laser beam. The interference pattern between the two halves of the beam creates the holographic information.

- Developing: The plate is chemically developed, revealing a microscopic surface relief pattern—a landscape of tiny grooves and ridges.

- Electroforming: The glass master is coated with silver and then placed in an electroforming tank. Nickel is deposited onto the surface, creating a "father" plate that is an exact metallic inverse of the glass master.

- Shim Generation: For large-scale production, additional "mother" and "son" shims are generated from the father plate to avoid wearing out the original master.

This entire sequence is a high-tech, high-cost process that forms the primary barrier against counterfeiting.

Mass Production: The Embossing, Printing, and Finishing Stages

With the master shim created, we are ready for mass production. However, this still isn't "printing." It's a high-pressure, high-temperature physical replication process called embossing, followed by several finishing steps.

The master shim is mounted onto a roller. A roll of specialized multi-layer film is then fed through the machine. Intense heat and pressure are applied, physically pressing the microscopic pattern from the shim into the surface of the film.

This is another critical link in the chain. The embossing machine itself is a piece of specialized industrial equipment. The film we use isn't simple plastic; it's a composite material often with a PET base, a release coat, and an embossing lacquer layer designed to receive the impression perfectly. After embossing the holographic image, the process continues:

- Metallizing: The embossed film is placed in a vacuum chamber where a micro-thin layer of aluminum is deposited, giving the hologram its characteristic metallic shine and reflectivity.

- Adhesive Coating: The appropriate adhesive is applied. This could be a standard pressure-sensitive adhesive or a special tamper-evident one that leaves a "VOID" pattern.

- Die-Cutting: Finally, the rolls are run through a die-cutting machine that cuts the stickers into their final shape and size, whether square, round, or custom.

Each of these steps requires precision machinery and expertise, adding further layers of difficulty for any potential counterfeiter.

Final Approval: How Are Your Hologram Stickers Inspected and Packaged?

The final step is often overlooked but is crucial for security: rigorous quality control and secure packaging. A flaw in a sticker can compromise its security, and insecure packaging can lead to theft before the stickers even reach the client.

Every batch of stickers undergoes both automated and manual inspection. We check for defects in the hologram, issues with the adhesive, and accuracy of the die-cut. We also verify any variable data, like serial numbers, to ensure 100% accuracy.

I insist on this step being airtight. What's the point of creating a high-security hologram if the serial numbers are duplicated or if a sheet of stickers has a flaw that makes it easy to peel? After inspection, the stickers are shrink-wrapped, boxed, and often sealed with their own security tape. This ensures a proper Chain of Custody right to the client's door. We treat the finished stickers with the same security as the process that created them. It completes the industrial chain, ensuring the integrity of the product from concept all the way to application.

The QC Checklist

- Holographic Quality: Is the image bright, clear, and free from spots or cloudiness?

- Variable Data Check: Are all serial numbers, QR codes, or other unique identifiers correct and sequential?

- Adhesive Performance: Does the adhesive meet the specified performance for the application (e.g., tamper-evidence works correctly)?

- Finishing Accuracy: Are the die-cuts clean and centered? Is the sticker size within tolerance?

- Secure Packaging: Are the finished goods counted, logged, and packaged securely to prevent in-transit theft?

This final step ensures that the security engineered into the hologram is delivered intact to the end-user.

Conclusion

Hologram manufacturing is an industrial process, not just printing. This complex chain, from optical engineering to precision embossing, is the very foundation of its anti-counterfeiting strength.

From Your Concept to a Secure Reality with ProtegoSeal

Understanding the hologram manufacturing process is key to creating an effective security solution. At ProtegoSeal, we master this entire industrial chain to produce hologram stickers that provide uncompromising security. Contact us to turn your security concept into a physical, counterfeit-proof reality.