You're looking at a spec sheet for security seals, and you see two options: HDPE and PP. They're just plastics, right? You pick the one that's slightly cheaper, thinking it won't make a difference.

This seemingly small choice can be the difference between a seal that reliably protects your cargo and one that can be defeated or fails under stress without a trace. Choosing wrong is a hidden vulnerability that can cost you an entire shipment.

While both High-Density Polyethylene (HDPE) and Polypropylene (PP) are durable, PP is generally stiffer and stronger in tension, while HDPE is more flexible and excels in cold temperatures. Crucially, HDPE's tendency to show stress-whitening gives it a slight edge in providing clearer, more obvious tamper evidence.

Based on my years of experience, starting from quality control and inspecting failed seals, I always advise clients to evaluate seal materials using a two-layer model. The first layer is "Base Physical Performance," which includes strength and durability. This is the basic entry ticket for a seal to even be considered a professional product. The second, and far more decisive layer, is its "Tamper Evidence Presentation"—the material's ability to retain clear, unmistakable evidence of an attack. When we're choosing between HDPE and PP, the real, strategic decision is almost always made on this second layer.

Material Strength: How Do HDPE and PP Affect Security Seal Durability?

You sealed a trailer perfectly, but the seal was found broken on arrival. Was it tampered with, or did it just fail?

This ambiguity is a security nightmare. The base material's strength is what prevents accidental breakage, ensuring that a broken seal is a clear indicator of intentional action, not just a product failure.

Both plastics are tough, but they behave differently under stress. Understanding this is Layer 1 of our evaluation. I was once involved in a case where a client's seals kept breaking on a route with very rough roads. The issue wasn't tampering; it was material fatigue from constant vibration. We switched their seal material, and the problem disappeared. This is why the basics matter.

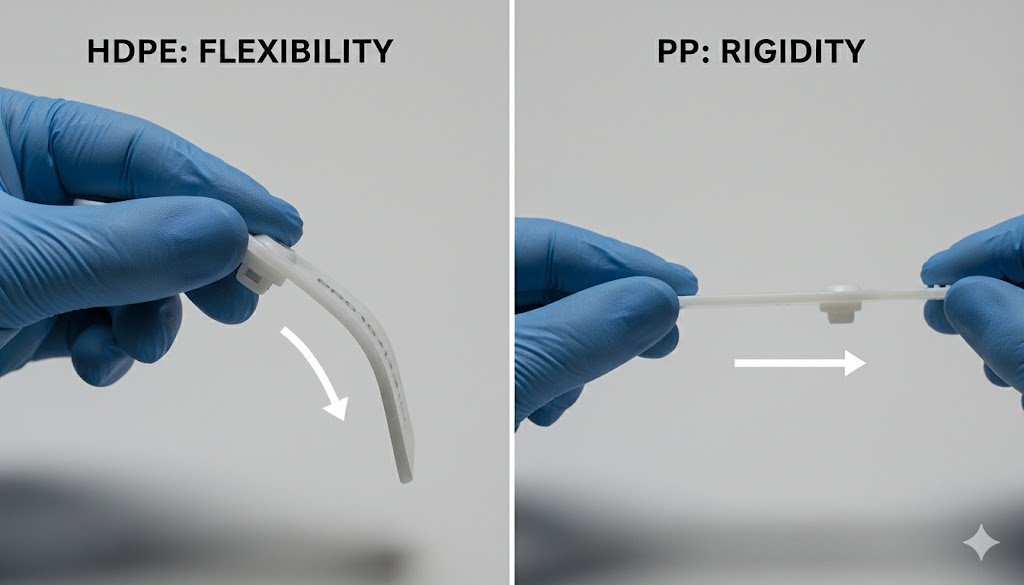

- High-Density Polyethylene (HDPE): HDPE is known for its excellent impact resistance and flexibility. Its long polymer chains can absorb energy without cracking. This makes it ideal for situations where the seal might be bumped, knocked, or subjected to vibration during transit.

- Polypropylene (PP): PP is generally stiffer and has a higher tensile strength than HDPE. This means it's stronger when you pull on it. Its more rigid, crystalline structure makes it very resistant to being stretched or elongated.

| Property | High-Density Polyethylene (HDPE) | Polypropylene (PP) |

|---|---|---|

| Tensile Strength | Good | Excellent |

| Impact Resistance | Excellent | Good |

| Flexibility | High | Medium (More Rigid) |

Climate Adaptability: HDPE vs. PP Security Seals in Extreme Temperatures?

Your seals are applied in a +40°C Dubai port and will be opened in a -20°C warehouse in Moscow. Will the material survive?

A plastic that performs perfectly at room temperature can become brittle and snap in the cold, or soften in extreme heat. This can lead to false tamper alarms or make the seal easier to defeat.

This is another critical part of Layer 1 analysis. The material's behavior at temperature extremes is a fundamental aspect of its reliability. Choosing the wrong plastic for your shipping route is setting yourself up for failure.

Cold Weather Performance

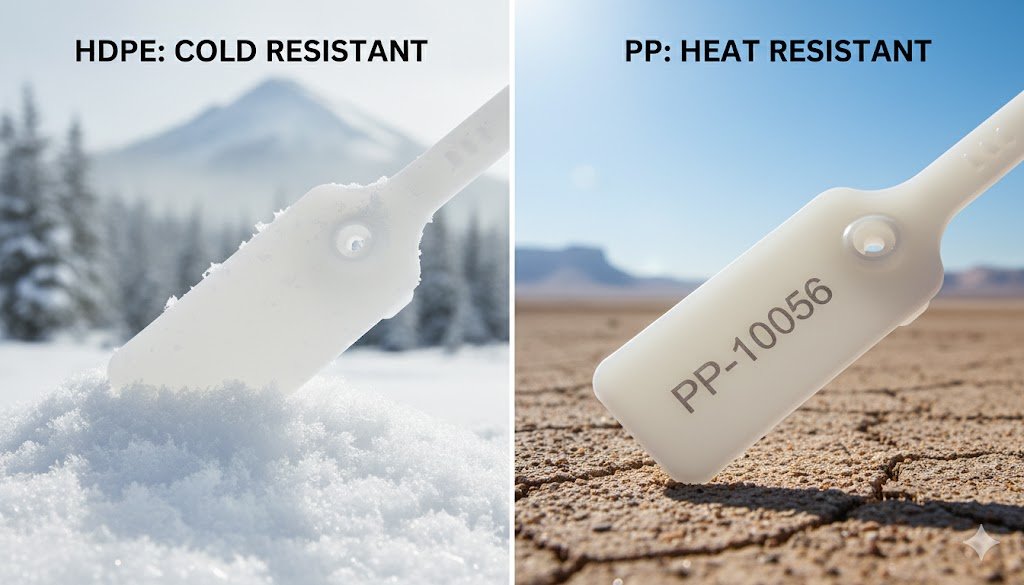

HDPE is the clear winner in cold environments. It has a much lower "glass transition temperature," which is the point where a polymer becomes hard and brittle. HDPE maintains its flexibility and impact resistance even in freezing conditions, making it the superior choice for refrigerated transport or shipments to cold climates. PP, in contrast, can become brittle and may crack if stressed at low temperatures.

Hot Weather Performance

PP stands out in hot conditions. It has a higher melting point (around 160°C) compared to HDPE (around 130°C). This makes it more stable and rigid in high-temperature environments, such as containers sitting under the sun in the Middle East or Southeast Asia. It's less likely to soften or deform.

Tamper Evidence: Which Plastic Makes Tampering on a Security Seal More Obvious?

A thief tries to pry the seal open just enough to access the goods and then presses it back together. How do you spot this?

This is the most important question. This is Layer 2 of our model—the seal's ability to be a good "witness." The best material isn't just strong; it's one that screams "I've been touched!"

This is where the subtle differences between the two plastics become a major strategic factor. In my Quality Control days, we would actively try to defeat seals to see how they would react. This is what we found.

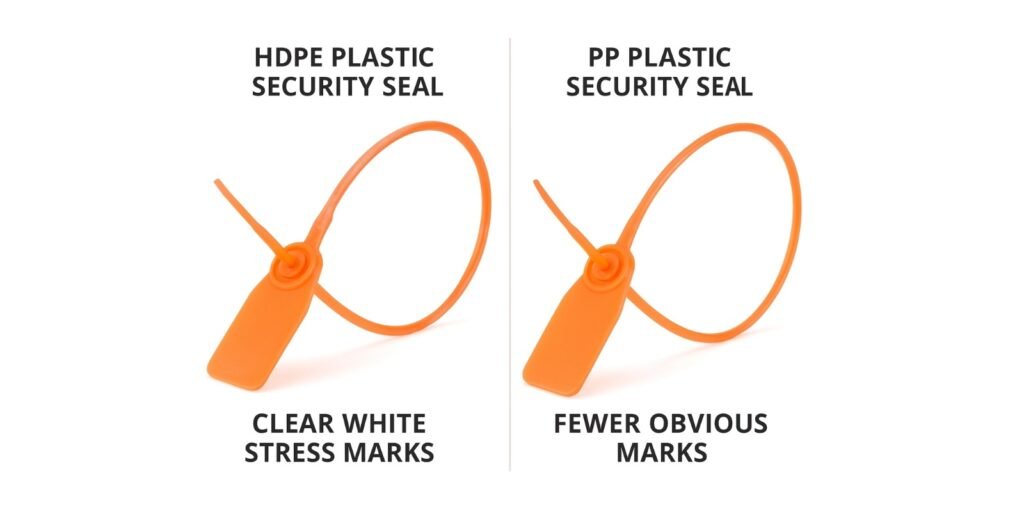

HDPE often has a distinct advantage in showing evidence of physical manipulation. When you bend, stretch, or try to pry open an HDPE seal, it exhibits a phenomenon known as "stress whitening" or "blushing." The plastic in the stressed area turns a milky white color. This is a permanent, highly visible scar that is incredibly difficult to hide, providing a clear and immediate visual cue that tampering has occurred.

PP is a very strong plastic, but it is generally less forthcoming with evidence. While it will certainly break if enough force is used, it tends to be more resilient to minor bending and may not show the same obvious stress-whitening as HDPE. A subtle, low-force attack might leave less of a mark, requiring a more careful inspection to detect. Both materials show evidence of heat-based attacks (like melting or discoloration), but for physical prying and bending, HDPE is often the better informant.

Cost-Benefit Analysis: Price vs. Value When Choosing a Security Seal Material

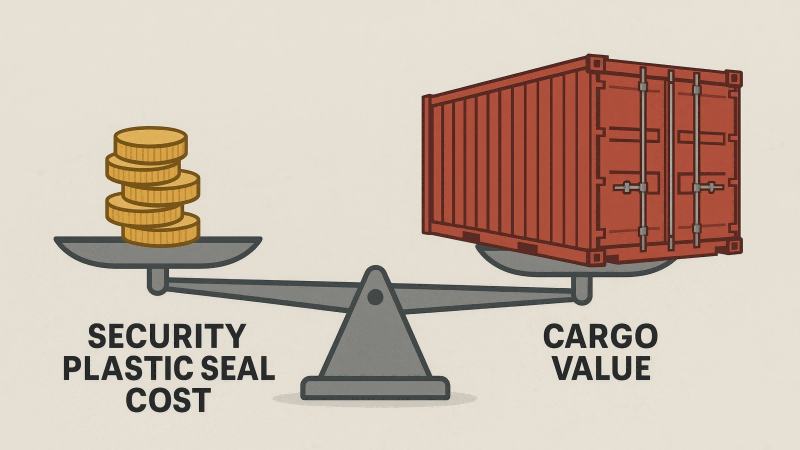

PP is often slightly cheaper than HDPE. Does this mean it's the more cost-effective choice?

Absolutely not. The unit price of the seal is almost irrelevant compared to the value of the cargo it protects. The true "cost-benefit analysis" comes from selecting the material that provides the highest level of reliable security for your specific needs.

Thinking about cost per seal is the wrong metric. Think about the cost of a single lost or compromised shipment. That can run into the tens of thousands, or even hundreds of thousands, of dollars. If spending an extra cent per seal on a material like HDPE gives you a more reliable and easily verifiable "tamper witness," the return on investment is immense.

A purchasing decision based solely on minimizing the upfront cost of the seal, without considering the application, climate, and tamper-evidence properties, is a classic example of "penny wise, pound foolish." The most cost-effective seal is the one that works flawlessly and removes all doubt during inspection.

Application-Based Decision: Selecting the Right Security Seal Material for Your Cargo

So, how do I apply all this to make a final decision for my specific shipment?

You need to map your primary risks to the material's strengths. Match the seal to the journey and the inspection process.

Let's put the two-layer model into a practical decision-making framework. I guide my clients through these questions:

- What is your primary route?

- Cold Climate / Reefer Truck: The choice is simple. HDPE is the only reliable option due to its superior cold-weather performance.

- Hot Climate / Desert Route: PP's high heat resistance makes it a very strong contender here.

- What is your primary inspection method?

- Quick Visual Check: If your receivers will only give the seal a quick glance, you need the most obvious tamper evidence possible. HDPE's stress-whitening is a major advantage here.

- Detailed Forensic Inspection: If you have a detailed security protocol, both materials can work, but you need to train your team on what to look for with each.

- What type of seal are you using?

- Fixed-Length / Padlock Seals: These are often subject to pulling and twisting. PP's tensile strength is an advantage.

- Adjustable Pull-Tight Seals: These are often bent and manipulated. HDPE's flexibility and tamper evidence are key here.

In most general-purpose scenarios, HDPE provides a slightly more balanced profile with a significant edge in tamper evidence, making it an excellent default choice.

Conclusion

The choice between HDPE and PP is not about which plastic is "better," but which is better for your specific security needs. By evaluating both their physical performance and, more importantly, their ability to provide clear tamper evidence, you can make a strategic choice that enhances your cargo's security.

Make a Strategic Choice with ProtegoSeal

Don't guess on material selection. At ProtegoSeal, we help you analyze your shipping routes and security needs to select the material—HDPE or PP—that offers the most robust protection for your cargo. Contact us to ensure your security seal is a reliable witness.