The dangerous assumption that 'High-Security' bolt and cable seals are interchangeable leads to using the wrong tool for the job, creating a security gap that a thief could exploit or an auditor might miss and putting your entire shipment at risk.

The primary difference is their physical structure: a bolt seal is a rigid, two-part system designed for specific locking points, while a cable seal is a flexible, adjustable wire for versatile applications. This fundamental design difference dictates their security logic, best use cases, and the type of tampering evidence they provide.

I've spent over a decade in this industry, and this is a point I stress constantly with my clients: a bolt seal and a cable seal are designed from first principles to solve completely different physical locking problems. One acts as a "rigid filler," while the other is a "flexible fastener." Their ISO rating only proves they meet a certain strength standard; it absolutely does not mean their functions are interchangeable.

More importantly, they follow completely different logic in how they leave tampering evidence. The bolt seal's evidence is about "fracture," while the cable seal's is about "irreversible damage" and "slack." Choosing the right seal is actually about choosing the type of "criminal evidence" that is easiest for you to find and verify.

Structure and Mechanism: The Difference Between Rigid Locking and Flexible Adjustment?

You've tried to use a bolt seal on a valve, and it won't fit. You've seen a cable seal on a container handle, and it looks loose.

This is because their locking mechanisms are designed for entirely different physical scenarios. A bolt seal fills a defined space with a rigid pin, while a cable seal cinches down to secure irregular shapes.

Let's break this down. The physical form is not just a cosmetic difference; it is the essence of the tool.

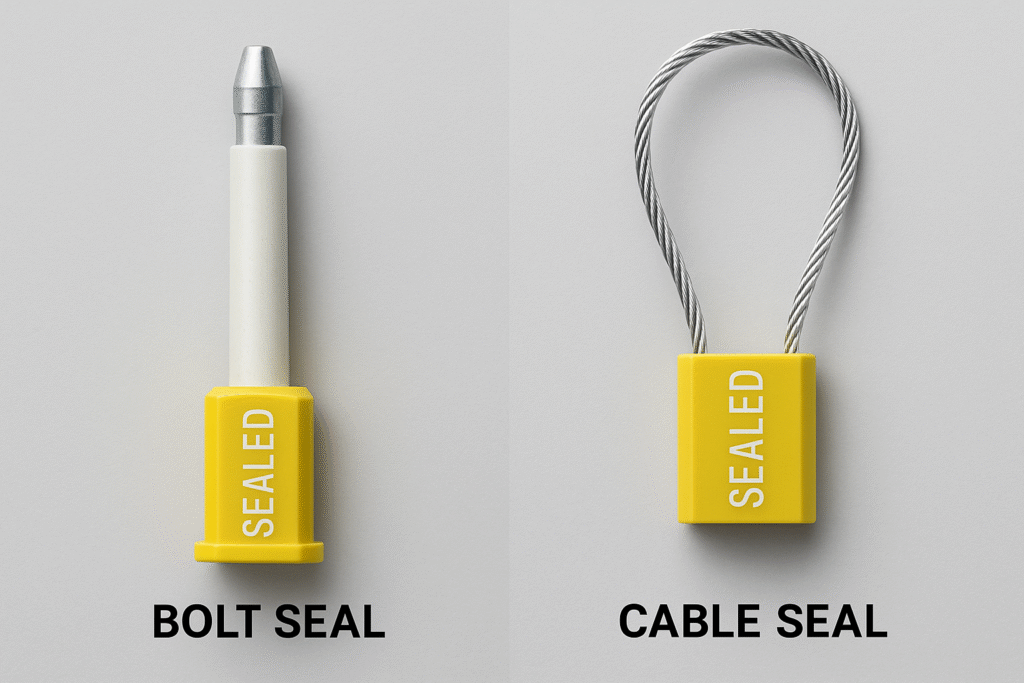

The Bolt Seal: A Rigid Plug

Think of a bolt seal as a specialized, single-use plug. It consists of two parts: a steel pin and a locking body. When you click them together, the pin enters the body and an internal spring-loaded ring snaps into a groove on the pin. It's designed to precisely fit the standardized holes on a shipping container's cam-lock handles. Its job is to be a rigid obstruction. It doesn't tighten; it fills the space, preventing the handles from moving.

The Cable Seal: A Flexible Noose

A cable seal, on the other hand, is like a high-security, self-locking lasso. It's a single unit comprising a length of steel aircraft cable attached to a locking body. You feed the free end of the cable through the opening and into the body's one-way locking mechanism. The mechanism allows the cable to be pulled tighter but never loosened. Its function is to cinch down and secure objects of varying sizes and shapes.

| Feature | Bolt Seal (Rigid Filler) | Cable Seal (Flexible Fastener) |

|---|---|---|

| Form | Two-part; pin and body | One-piece; cable and body |

| Mechanism | Internal ring locks into a pin groove | One-way clutch locks the cable |

| Application Logic | Fills a standardized space | Cinches down on an irregular shape |

Security Level Showdown: Can Both Meet the High-Security Standard?

You see "ISO 17712 'H' Certified" on both seals. Doesn't this mean they offer the same level of security?

Yes, both can achieve the "H" rating, but it only certifies their physical strength against brute-force attacks. It does not mean they provide security in the same way or that they are equally secure in every application.

This is one of the biggest points of confusion I see. The ISO 17712 "H" classification is a laboratory benchmark for physical resilience. To earn it, both seal types must withstand formidable tensile, shear, and impact forces. It proves the material is strong. However, how that strength is applied in the real world is completely different.

As I mentioned earlier, their core security logic diverges. A bolt seal relies on its "fracture evidence." The only way to remove it is to cut the pin, providing obvious, undeniable proof of entry. A cable seal relies on "irreversible damage." When the cable is cut, the ends fray in a way that is impossible to fuse back together perfectly. Any attempt to tamper with the lock body also leaves clear signs. The strength is comparable, but the type of evidence you are looking for during an inspection is completely different. Ultimately, the application dictates which form of security is truly more effective.

Core Advantages: The Absolute Strength of Bolt Seals vs. The Versatility of Cable Seals

So, if strength is similar, what is the clear advantage of one over the other?

The bolt seal's advantage is its absolute, unambiguous security when used on a container. The cable seal's advantage is its incredible versatility to secure almost anything else.

This is where you choose your tool for the job. I've seen customers try to force a cable seal to do a bolt seal's job and vice-versa, creating unseen vulnerabilities.

The Bolt Seal's Advantage: Optimized Security

For a standard shipping container, the bolt seal is superior. Its rigid pin perfectly fits the hardware, leaving no slack or room for manipulation. A thief cannot wiggle it, shim it, or try to bypass it. Its security is binary: it is either fully intact, or it is broken. This simplicity is its greatest strength in the standardized world of intermodal freight.

The Cable Seal's Advantage: Adaptable Versatility

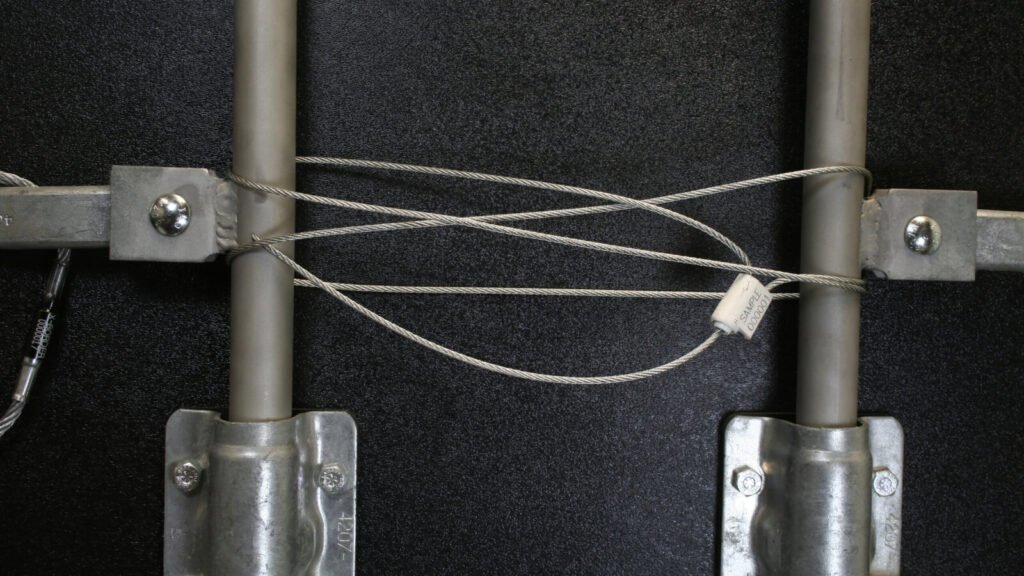

The cable seal's superpower is its ability to adapt. Think of securing a tanker truck's hatch, a set of valves on a chemical tote, or the roll-up door on a delivery truck. These have irregular shapes and non-standard locking points. A bolt seal would be useless here. The cable seal can be looped through, around, and over these obstacles and cinched down tight, providing a secure fit where no other seal can. Its flexibility is its defining advantage for a wide range of asset protection scenarios.

Application Guide: When to Choose a Bolt Seal, and When a Cable Seal is Better

How do you make the right call in a real-world shipping scenario?

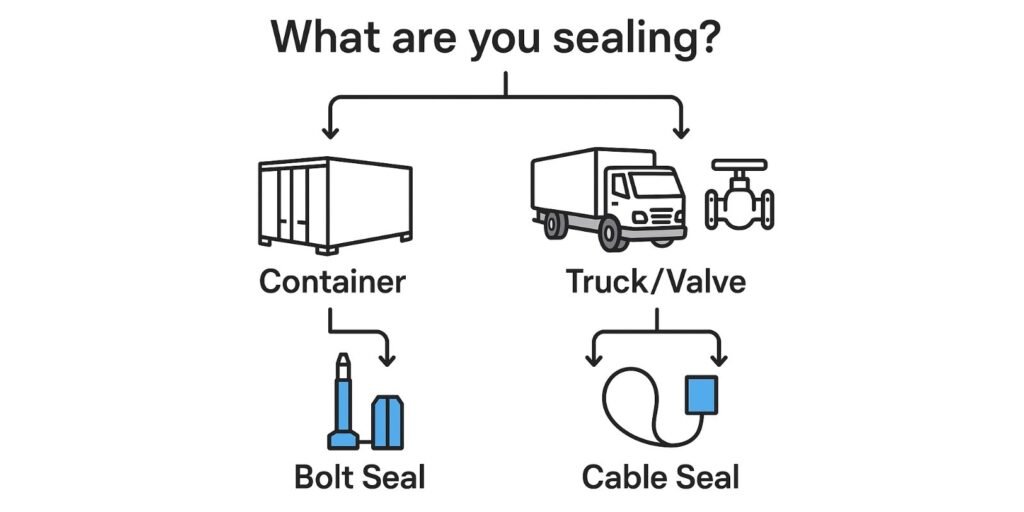

The choice is dictated by the locking hardware. If you are sealing a standard ISO container for international shipping, always use a bolt seal. For almost everything else, a cable seal is likely the better choice.

To avoid making a costly mistake, I give my clients this simple rule of thumb. This isn't just about best practice; in the case of container shipping, it's often a regulatory requirement for programs like C-TPAT.

Use a Bolt Seal for:

- All ISO Shipping Containers: The hardware is specifically designed for bolt seals.

- Trailer Door Swing Handles: Where the two handles have aligned holes designed for a rigid pin.

Use a Cable Seal for:

- Truck Roll-Up Doors: The cable can be looped through the door hasp and latch.

- Tanker Trucks: Securing hatches, valves, and outlets.

- Railcars: Locking various types of hasps and levers.

- Air Cargo Containers: Securing zippers or hasps on unit load devices (ULDs).

- High-Value Totes and Drums: Where you need to secure a lid or valve system.

Choosing the wrong one is a major security failure. Using a cable seal on a container can leave dangerous slack; trying to use a bolt seal where it doesn't fit means the asset isn't sealed at all.

Cost and Handling: Making the Most Cost-Effective Purchasing Decision

Is there a significant difference in price or handling that should influence my decision?

While prices can be similar, the real cost lies in handling and risk. The most cost-effective decision comes from choosing the seal that is fastest to apply correctly and provides the clearest audit trail for your specific application.

In purchasing, don't just look at the unit price. Consider the "total cost of security." I've seen companies choose the "cheaper" seal only to suffer from application errors that cost them dearly.

- Handling Speed: For a container, a bolt seal is faster. You simply click it into place. A cable seal requires threading and pulling, which can take slightly longer, especially at scale.

- Error Rate: A bolt seal application is almost foolproof. It either clicks or it doesn't. A cable seal must be cinched down tightly; if an operator leaves it loose, it creates a significant security vulnerability. The risk of human error is slightly higher.

- Inspection Clarity: The "broken" evidence of a bolt seal is instant and obvious. The "cut/frayed" evidence of a cable seal is also clear, but requires a closer look.

The most cost-effective choice is the one that minimizes risk and maximizes efficiency. For a container, that is the bolt seal. For a valve, it is the cable seal. Matching the tool to the task is always the cheapest option in the long run.

Conclusion

A bolt seal is a rigid plug for a standard hole; a cable seal is a flexible rope for a custom fit. While both can be high-security, they are not interchangeable. They are different tools that provide different types of evidence for different security scenarios.

Choose the Right Tool for the Job with ProtegoSeal

Don't guess which seal is right for your shipment. At ProtegoSeal, we help you select the correctly certified seal—bolt or cable—that provides the most effective security for your specific application. Contact us to ensure your security is optimized, not compromised.