A generic holographic label is a marketing gimmick, not a security feature. When counterfeiters can buy the same "stock" hologram you use, your investment is wasted and your brand remains exposed.

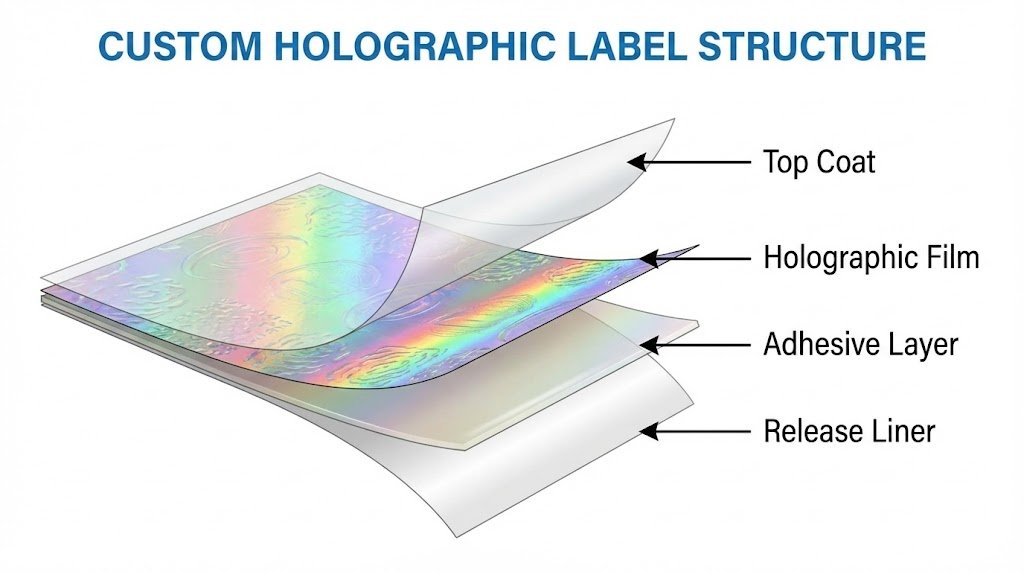

The effectiveness of a custom holographic label depends on the precise calibration of its material chemistry with its optical exclusivity. This guide explains the manufacturer's logic: security is a three-part system of chemical formula (adhesives), optical design (holograms), and industrial standards (durability).

As a manufacturer, I must stress one point: a security label is an engineered system, not just a sticker. The biggest failure I see is a beautiful, expensive hologram applied to a cheap paper substrate with the wrong glue. It looks great until it gets damp and falls off, or a thief peels it away without a trace. The foundation of security is not the shiny image; it is the deep match between the adhesive system and the surface it needs to protect. Without this foundation, the entire structure collapses.

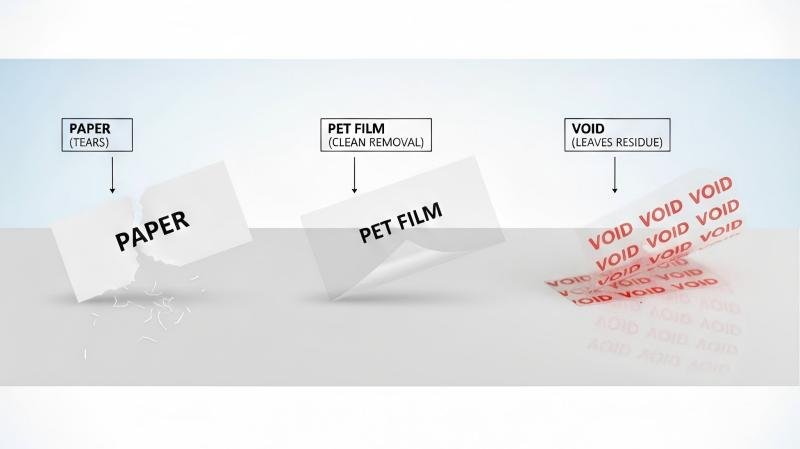

Comparing Security Label Substrates: Paper, PET, and VOID Materials

Choosing the wrong base material for your holographic label guarantees failure. A paper label disintegrates in moisture, while a standard PET label might not show tampering, rendering your security useless.

The substrate choice depends on your product's environment and security risk. Destructible Paper is for low-cost, indoor applications; PET offers durability against weather; and VOID materials provide the highest level of tamper evidence.

Substrate Selection: A Manufacturer's Breakdown

The substrate is the chassis of your security label. Building a high-tech hologram on a weak chassis is a waste of money. Here’s how I advise clients to choose:

Destructible "Egg-Shell" Paper: This is a low-cost option designed to fracture into tiny pieces upon removal. It's excellent for indoor warranty seals on electronics where moisture is not a concern. However, I've seen it fail spectacularly when used on shipping cartons exposed to humidity, where it can weaken and peel off. It is a one-trick pony: great at preventing reuse, but poor in durability.

Polyester (PET): This is the durable workhorse. PET is a plastic film that resists water, oil, and temperature fluctuations. It’s the standard for automotive parts, outdoor equipment, and anything requiring long-term adhesion. Its weakness? A standard PET label can sometimes be peeled off intact if the adhesive isn't aggressive enough.

VOID Polyester: This is PET engineered with a hidden security layer. It offers the same durability as standard PET but leaves a clear "VOID" or custom message if removal is attempted. This is the evidentiary standard, combining durability with undeniable proof of tampering. It's the material specified by most high-value goods manufacturers.

| Substrate | Best For | Key Weakness |

|---|---|---|

| Destructible Paper | Indoor, dry applications | Poor weather/chemical resistance |

| Standard PET | Durability, weather resistance | No built-in tamper evidence |

| VOID PET | High-security applications | Higher cost |

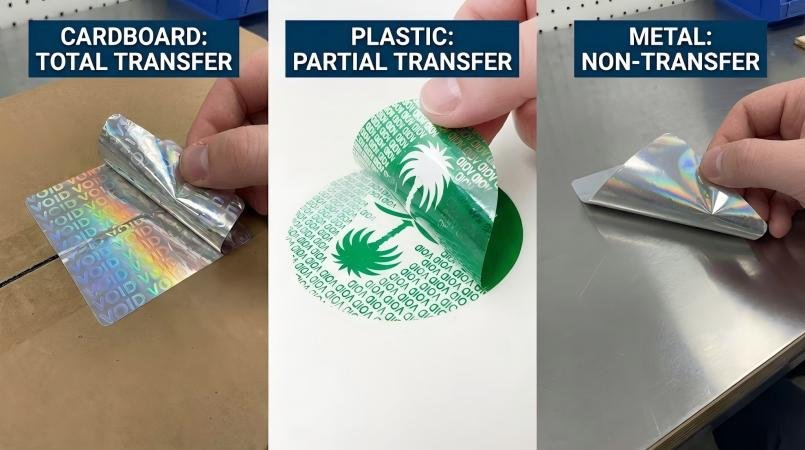

What Are the Best Residue Options for Your Application?

Your holographic label peels off cleanly, leaving no evidence of tampering. A thief simply moves your expensive, authentic label to a fake product, and your security system has failed.

The residue pattern must match the surface energy of your product. Total Transfer for porous cardboard, Partial Transfer for versatile packaging, and Non-Transfer for high-value reusable assets like aircraft parts or server racks.

The Chemistry of Evidence

The "VOID" message is a function of adhesive chemistry. As per standards from the Pressure Sensitive Tape Council (PSTC), the adhesive must be selected based on the surface it will bond to.

Total Transfer: This option dumps the entire adhesive layer onto the surface. It is designed for low-energy, porous surfaces like raw cardboard or wood. The adhesive physically anchors into the fibers, making clean removal impossible. It is maximum evidence, maximum mess.

Partial Transfer: This is the most common and versatile choice. The adhesive layer is designed to split. A "VOID" pattern appears on both the surface and the back of the label. It offers a clean, legible message and works well on most coated paper, plastics, and metals. It is the safest bet for retail packaging.

Non-Transfer (Zero Transfer): This is for protecting the asset itself. The "VOID" message appears only on the label, leaving the surface perfectly clean. This is critical for high-value goods like automotive paint, glass, or electronics that cannot be damaged by sticky residue. However, it requires a clean, high-energy surface to function correctly.

The Role of Custom Branding in Enhancing Label Security

Using a generic "stock" hologram is like using the key "1234" for your bank account. Counterfeiters can buy the same stock patterns, making your security label worthless.

Custom branding embeds your unique identity directly into the hologram, transforming it from a commodity sticker into a feature that is exclusively yours. This requires custom tooling, making it exponentially harder for counterfeiters to replicate.

Turning a Label into a Fingerprint

A stock hologram offers zero exclusivity. True security comes from proprietary optical features linked directly to your brand.

Custom Holographic Image: The foundation is a hologram created from your artwork. But we go deeper. We can embed covert images or text that are only visible at a specific viewing angle—something impossible to see head-on.

Branded Micro-text: Within what appears to be a solid line in the hologram, we can embed your company name in text less than 0.2mm high. This requires a microscope to see and is far beyond the resolution of a scanner. As defined by ISO 12931, such forensic features provide a high level of authentication.

Serialized Numbering: We can laser-etch a unique serial number onto each holographic label. When linked to a database, this allows for track-and-trace capabilities, turning your security label into a smart-label for fighting diversion in your supply chain.

How Advanced Holographic Features Prevent Counterfeiting

Basic rainbow holograms are easy to fake. If your hologram relies on a simple 2D rainbow effect, it provides a false sense of security. Fraudsters can easily mimic this look with cheap foils.

Advanced holograms use multi-channel and multi-level optical effects that cannot be reproduced without access to the original master plate. Features like 3D depth, kinetic animation, and guilloche patterns act as optical locks.

The Science of Optical Security

The International Hologram Manufacturers Association (IHMA) registers security holograms to prevent duplication. But the technology itself is the best defense.

2D/3D and 3D Effects: This creates true parallax and depth. As you tilt the label, you can "look around" the foreground object to see the background. A fake hologram is a flat image that simply shifts color.

Kinetic Effects (Animation): We can embed images that appear to move, expand, or radiate as the viewing angle changes. Think of zooming lines or rotating globes. These dynamic effects are extremely difficult to replicate because they are encoded at a nanoscopic level in the master hologram.

Guilloche Patterns: These are complex, fine-line patterns similar to those on banknotes. They are mathematically generated and nearly impossible to scan or physically copy with precision. When integrated into a hologram, they provide an immediate red flag if the lines appear blurry or broken on a counterfeit.

5 Essential Factors for Manufacturer-Grade Security Design

Your label looks secure in the lab, but fails in the real world. It peels off in the cold, fades in the sun, or can be removed with a common solvent, leaving your product vulnerable during shipping and storage.

A true security solution is a three-way calibration of optical design, chemical formulation, and industrial durability. You must verify these five factors with your manufacturer before placing an order.

Master Exclusivity: Does the manufacturer guarantee that your holographic master plate is exclusive to you and will be securely stored or destroyed after production? Ask for this in writing.

Adhesive Match: Have you tested the specific adhesive on your product's actual surface? A label for a cardboard box needs a different glue than one for a powder-coated metal part. Demand samples.

Durability Specs: Does the label meet industrial standards for abrasion, chemical, and UV resistance? Ask for the technical data sheet (TDS). A label that fades in six months is a total waste of money.

Application Process: Will the labels be applied by hand or by machine at high speeds? The label's liner and stiffness must be designed for your application process to avoid costly downtime.

Supplier Security: Is the manufacturing facility itself secure? A supplier with poor access control could be the source of leaks, with your genuine labels being sold out the back door. Verify their security protocols.

Conclusion

A custom holographic tamper-evident label is a system, not a sticker. Success depends on calibrating optical exclusivity with the right chemical foundation (substrate and adhesive) to match your product's surface and environment.

Engineer Your Security with ProtegoSeal

Stop using generic labels that offer a false sense of security. At ProtegoSeal, we are manufacturers who understand that security is an engineering discipline. We build custom holographic solutions from the ground up, starting with the right materials. Contact us today to get a technical consultation and test samples for your specific application.