Choosing the wrong tamper-evident label for your packaging is a costly mistake. It offers a false sense of security, leaving your products vulnerable and your investment wasted.

To choose the right label, you must match the technology to your packaging material. For cardboard, use aggressive fiber-tearing adhesives. For plastics, use VOID residue or destructible vinyl. For glass and metal, non-residue VOID labels work best to leave a clean surface.

My core piece of advice to all my clients is this: never start by choosing the label; start with your packaging surface. I've seen so many people make the same mistake. They get excited about a technology—like how "VOID" sounds cool and high-tech—and then try to force it onto their packaging. This is completely backward. The correct approach is to let your material—whether it's cardboard, plastic, or glass—dictate the security technology you need. If you get this wrong, you haven't bought security; you've bought a roll of expensive stickers that are waiting to fail.

What Are the Core Mechanisms of Tamper Evidence?

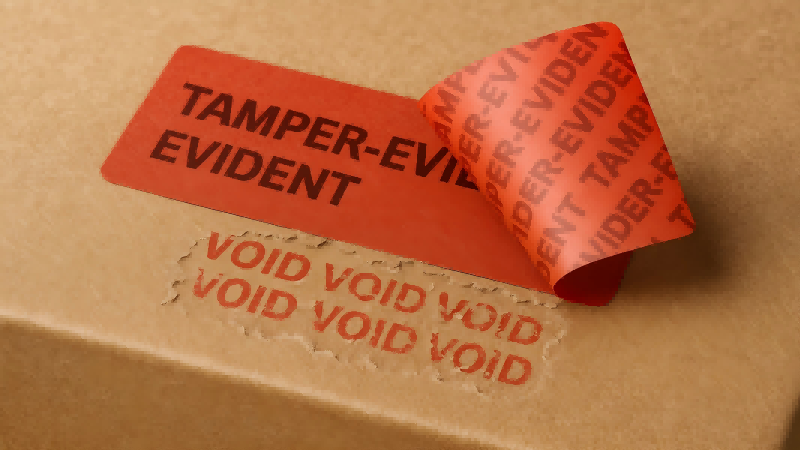

You see a label that says "tamper-evident," but you don't really understand how it works. This makes you doubt if it can truly protect your assets or if it's just a marketing gimmick.

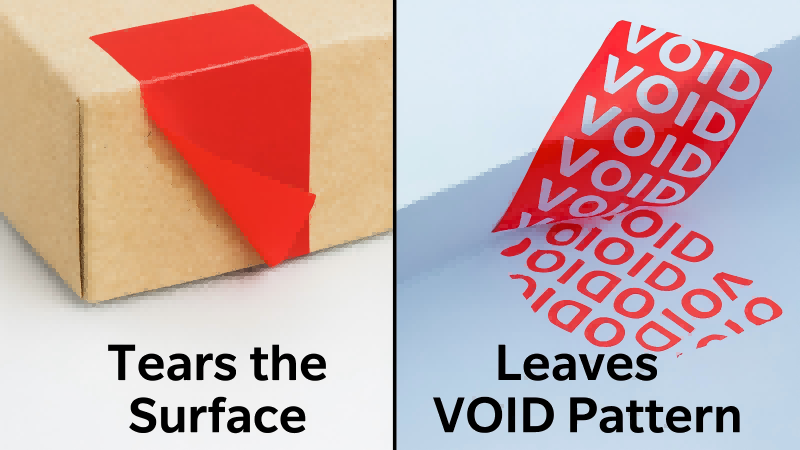

Tamper evidence works through one of two principles: either the label's adhesive is stronger than the packaging surface, causing the package to tear (fiber-tear), or the label itself is designed to self-destruct or split into layers (VOID/destructible) when removed.

In my years, first in quality control and now in sales, I've learned that all these fancy labels boil down to a simple battle of materials. It's about engineering a failure point. The goal is to ensure that something is irreversibly damaged during a removal attempt. Where that damage occurs is the key.

Principle 1: Structural Failure of the Packaging

This is the "brute force" method. The label is made with an extremely aggressive adhesive that bonds so powerfully to the surface that it's impossible to peel off. When someone tries to remove the label, the packaging material underneath—like the top layer of a cardboard box—rips apart. The evidence isn't on the label; it is the visibly destroyed packaging.

Principle 2: Self-Destruction of the Label

This method is more surgical. The label itself is the weak link. It's designed to either break into tiny, impossible-to-reassemble pieces (destructible vinyl) or to separate into distinct layers, revealing a hidden message like "VOID" (VOID labels). This is used when the packaging surface must remain intact.

For Cardboard Packaging: Why Is Fiber-Tear Your Strongest Evidence?

You applied a standard security label to your cardboard boxes, only to find a thief peeled it off cleanly. The label failed, your goods were stolen, and you have no visual proof of tampering.

For porous, fiber-based surfaces like cardboard, a standard label won't work. You need a label with a specialized, high-tack adhesive that bonds so aggressively it fuses with the paper fibers. Attempted removal won't peel the label; it will rip the box itself apart.

This is one of the most common mistakes I see. People try to use a slick VOID label on a raw cardboard box. A thief can often peel it off with minimal effort because the adhesive can't get a good grip on the porous, dusty surface. For cardboard, you don't want the label to be the star of the show—you want the box itself to become the evidence.

The goal here is what we call fiber-tear. The label's adhesive permeates the top paper layer and creates a permanent bond.

- The Action: A thief tries to peel the label to discreetly open the box.

- The Result: The label's bond is stronger than the cardboard's internal strength. Instead of the label lifting off, a chunk of the box's surface rips away with it.

- The Proof: The box is visibly and irreparably damaged. There's no way to hide the tampering. The thief can't just slap the label back on and walk away.

This is the only way to truly secure corrugated or paperboard packaging. Don't let anyone sell you a standard VOID label for this job; demand a security label specifically engineered for fiber-tear.

For Plastic Containers: How Do You Select Between VOID Residue and Destructible Vinyl?

Your plastic containers are being tampered with, but you don't know which label is best. A VOID label seems good, but so does a destructible one, and choosing wrong could mean wasted money on an ineffective solution.

The choice depends on the plastic's surface energy and your desired outcome. For high-energy plastics like PET, a VOID label that leaves a clear residue works well. For low-energy plastics like PE or PP, a brittle, destructible vinyl label is often more reliable.

Plastic is tricky because there are many different types. Some are easy to stick to (High Surface Energy), while others are slick and repel adhesives (Low Surface Energy). This is where you need to match the technology carefully.

Option 1: VOID Residue Labels

These labels split into layers to leave an "OPENED" or "VOID" message. They are fantastic for showing clear evidence, but their adhesive needs a good surface to bond to. They work best on smoother, higher-energy plastics where the adhesive can really "wet out" or spread. A Total-Transfer VOID is a great deterrent, leaving a sticky, impossible-to-clean message on the container.

Option 2: Destructible Vinyl Labels

Think of an eggshell. These labels are made from an ultra-brittle material paired with an aggressive adhesive. The moment someone tries to peel it, the label shatters into tiny fragments. It is physically impossible to remove it in one piece. This is an excellent choice for textured plastics or those tricky low-energy surfaces (like squeezable bottles) where a VOID label's residue might not transfer perfectly.

| Feature | VOID Residue Label | Destructible Vinyl Label |

|---|---|---|

| Best For | Smooth, high-energy plastics (PET, PVC). | Textured or low-energy plastics (PE, PP). |

| Evidence Type | A clear message ("VOID") is left on the surface. | The label itself shatters into tiny pieces. |

| Main Advantage | Unambiguous "VOID" message. | Works on difficult surfaces; highly deterrent. |

For Glass and Metal: How Do You Achieve a Clean and Clear "VOID" Message?

You need to seal a metal cabinet or a glass jar, but you're worried about damaging the surface. A label that leaves a sticky, hard-to-clean residue would create a new problem for your customers or staff.

For non-porous, high-energy surfaces like glass and metal, a Non-Residue VOID label is the ideal solution. It provides clear tamper evidence by revealing a "VOID" message on the label itself upon removal, while leaving the pristine surface of your asset completely clean.

Glass and metal are perfect surfaces for adhesives. The bond is strong and predictable. But this is where I see a different kind of mistake: using a Full-Residue label when it's not needed. I had a client in the medical field who used them on stainless steel equipment cabinets. The security was great, but the staff spent hours scraping off sticky residue after every inspection. It was a logistical nightmare.

The solution was simple: switch to a Non-Transfer (or Non-Residue) VOID label.

Here’s how it elegantly solves the problem:

- The Technology: The label is engineered so that the "VOID" message appears on the face of the label when it's peeled away. The color or metallic layer that forms the letters separates internally.

- The Result: The surface of your glass or metal product remains perfectly clean. There is no adhesive mess to scrape off.

- The Proof: The removed label clearly displays the "VOID" message, making it impossible to re-apply. It provides undeniable evidence of tampering without creating a cleanup job.

What is a Quick-Reference Chart for Matching Labels to Packaging?

You're busy and need a simple way to remember which label to use. You can't afford to re-read a long article every time you need to make a purchasing decision for a new product line.

To make things easy, I've summarized my recommendations into a simple table. Find your packaging material, and it will point you to the right technology. This is the same logic I use when advising my own clients every day. Always start with the surface material.

| Packaging Material | Recommended Technology | How It Provides Evidence |

|---|---|---|

| Corrugated Cardboard | High-Tack Adhesive Label | Fiber-Tear: The box surface itself is ripped apart upon removal. |

| Paper / Paperboard | High-Tack Adhesive Label | Fiber-Tear: The paper surface is visibly damaged. |

| High-Energy Plastics (PET, PVC) | Full or Partial Residue VOID Label | Residue: An "OPENED" message is left on the plastic surface. |

| Low-Energy Plastics (PE, PP) | Destructible Vinyl Label | Fracturing: The label shatters into tiny pieces upon attempted removal. |

| Glass / Bare Metal | Non-Residue VOID Label | Clean Separation: "VOID" shows on the label, leaving the surface clean. |

Remember my golden rule: Always test samples on your actual product before placing a large order.

Conclusion

Choosing the right tamper-evident label starts with your packaging, not the label itself. By matching the technology to the surface, you ensure genuine security and avoid costly, ineffective solutions.

Find Your Perfect Packaging Match with ProtegoSeal

Stop guessing which security label is right for you. At ProtegoSeal, we help you select the precise tamper-evident technology for your specific cardboard, plastic, or glass packaging. Contact us for expert guidance and free samples to test on your products.