You're managing a busy warehouse. You need to secure canvas bags, roll cages, tanker valves, and everything in between. Stocking a different fixed-length seal for each job is a nightmare.

This creates inventory chaos, drives up costs, and worse, leads to staff using the wrong seal for the job, creating dangerous security gaps that leave your assets vulnerable.

An adjustable length plastic seal is the most versatile option because it is designed to eliminate variables. By being pulled tight to a "zero-gap" state, it transforms countless different locking applications into a single, uniform, and highly secure standard.

For years, I believed the magic of an adjustable seal was its flexibility. But after handling thousands of logistics cases, I saw the deeper truth. Its core design isn't about adapting to diversity; it's about eliminating the security risks that diversity creates. Logistics is a business of managing variables—different sizes, shapes, and locking points. An adjustable seal, through the simple act of pulling it tight, neutralizes these variables and forces a standardized, "zero-gap" state of security on everything it touches. It's a truly brilliant concept.

What Are the Limitations of Fixed-Length Plastic Seals for Logistics Operations?

You try to use a fixed-length padlock seal on a mail sack. The seal clicks shut, but there's a huge loop of plastic left hanging. Is that really secure?

Of course not. That gap is a massive vulnerability. This is the fundamental problem when you try to apply a fixed "constant" (the seal) to a world of variables (your cargo).

Fixed-length seals are excellent for standardized applications like truck trailer latches. But in general logistics, they quickly become a liability. Their rigid length is their biggest weakness. If the locking points are closer together than the seal's length, you are left with a dangerous gap. This slack can allow a thief to manipulate the contents, or in some cases, even slip the seal off without breaking it. To solve this, you'd have to stock 5 or 6 different lengths, creating a complex and expensive inventory management problem. It's an inefficient solution that often fails in the real world. A fixed-length seal is a specialist; a modern logistics operation needs a generalist.

How Does an Adjustable Length Plastic Seal Provide Tamper-Evident Protection for Different Cargo?

How can one single product secure both a tiny valve handle and a bulky roll cage door effectively?

The secret is in its two-part design: a flexible, serrated tail and a one-way locking mechanism. This system is designed to achieve a "zero-gap" state on demand.

This is where the design brilliantly neutralizes variables. You loop the tail of the seal through the locking points and feed it into the locking head. As you pull, an internal metal or plastic jaw allows the serrated tail to move in only one direction. You continue pulling until the seal is absolutely snug against the locking points, leaving no slack. This is the "zero-gap" state. At this point, the seal is permanently locked. The only way to remove it is to cut it. It doesn't matter if you pulled through 5cm of the tail or 30cm; the locking principle remains the same. It forces a custom fit every time, creating a consistent level of tamper-evident security across an infinite variety of applications.

What Are the Key Applications of Adjustable Plastic Seals Within the Supply Chain?

You understand the principle, but where does this versatility deliver the most value in your day-to-day operations?

From the warehouse floor to final delivery, these seals are the problem-solvers for non-standard security points. They are the true workhorses of the logistics industry.

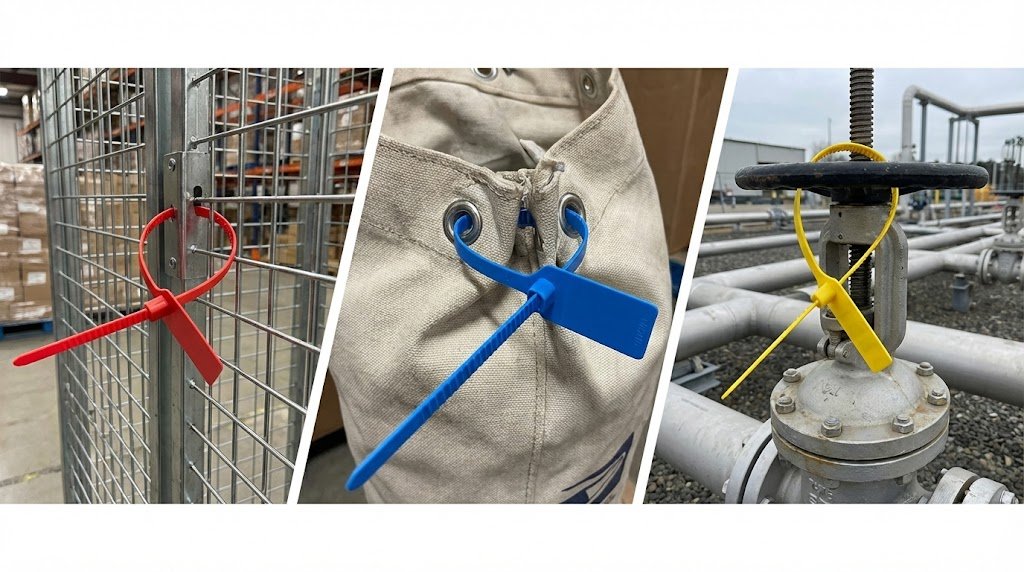

I've seen these seals deployed in dozens of industries, but their value shines brightest in these common logistics applications, all of which feature variable locking points:

- Roll Cages & Totes: Securing the doors of wire mesh roll cages used in supermarkets and distribution centers.

- Cash-in-Transit: Locking canvas or PVC bags used for moving cash and valuable documents, where the pull-tight action is essential.

- Airline & Catering Carts: Ensuring that in-flight service carts have not been tampered with before reaching the aircraft.

- Fire & Safety Equipment: Placing a seal on fire extinguisher pins shows that the device is fully charged and hasn't been accidentally discharged.

- Valves & Sprinklers: Securing valves in the "open" or "closed" position in industrial settings to prevent unauthorized operation, which is a critical safety lockout procedure.

In every case, the adjustable seal's ability to conform perfectly provides the security that a fixed-length seal simply cannot.

Is the Strength and Security of an Adjustable Security Seal Reliable?

You pull the seal tight. It feels secure, but it's just a thin strap of plastic. Can you really trust its strength?

This is a valid question I often get from clients moving from metal seals. The answer is yes, because its security isn't just about brute strength; it's about its tamper-evident design.

From my time in quality control, I can tell you that a well-made adjustable seal is surprisingly robust. Here's why you can trust its security:

| Feature | Security Implication |

|---|---|

| Material Choice | Made from high-grade polypropylene (PP) or nylon, offering a typical tensile strength of 15-50 kg. This is more than enough to prevent accidental breakage or casual tampering by hand. |

| Locking Jaw | A metal locking jaw insert provides a much stronger bite on the seal's tail, significantly increasing the force needed to defeat it. |

| Tamper-Evidence | The key is that it cannot be opened without being cut. Any attempt to defeat it will leave clear, irreversible evidence—a broken strap or a damaged locking head. |

While a plastic seal can be cut with a simple tool, its purpose is not to be an unbreakable barrier like a bolt seal. Its purpose is to provide immediate, undeniable evidence of tampering, a job it performs perfectly.

How Does a Versatile Plastic Seal Reduce Costs for a Logistics Company?

Beyond preventing theft, how does standardizing on a single, versatile seal actually save my company money?

The cost savings are significant and come from multiple areas of your operation. It's one of the easiest ways to improve your bottom line and efficiency simultaneously.

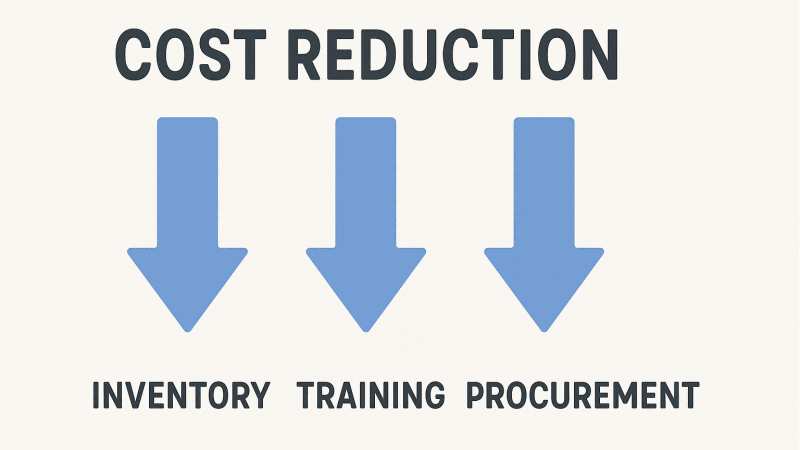

When I help a client switch from multiple fixed-length seals to a single adjustable model, we consistently see cost reductions in three key areas:

- Reduced Inventory Costs: Instead of stocking five or six different types of seals (SKUs), you now only need to stock one. This frees up warehouse space, reduces the capital tied up in inventory, and simplifies reordering. This is a core principle of lean inventory management.

- Simplified Procurement: Managing one supplier and one product is far simpler than juggling multiple. You can often get better volume pricing by consolidating all your purchases into a single, larger order.

- Lower Training & Error Costs: You only need to train your staff on how to properly use one type of seal. This reduces the chance of an employee using the wrong seal for the job, a mistake that can lead to a costly security breach. The simplicity of "pull it tight" is universal and hard to get wrong.

Conclusion

The adjustable length plastic seal is the most versatile logistics tool because it's designed to eliminate variables. It replaces inventory chaos and security gaps with a single, cost-effective, and uniformly secure solution for countless applications.

Eliminate Variables and Reduce Costs with ProtegoSeal

Stop managing a complex inventory of seals. At ProtegoSeal, our adjustable length plastic seals are engineered to provide maximum versatility and security for your logistics operations. Contact us to standardize your security and simplify your costs.