Struggling to find affordable security seals that don't fail? You're risking more than just cargo. The true cost of a bad seal can create a massive headache for your business operations.

The key is to look beyond the unit price. To find truly cost-effective seals, you must calculate the total cost of ownership, which includes communication efforts, time, and potential risks. Sourcing directly from a quality-focused factory is the best way to minimize these hidden expenses and secure real value.

It’s a common trap I see many importers fall into: focusing only on the price tag on the seal. But as my decade of experience has shown me, the real story of cost is much bigger than that initial number. A low price today can lead to significant losses tomorrow.

Let's break down what truly matters so you can find genuine, long-term value and protect your bottom line from these unexpected and damaging costs.

What Truly Drives the Cost of a Security Seal?

Wondering why seal prices vary so much between suppliers? It’s not random. The materials, design, and certifications directly impact your security level and, ultimately, your budget.

A seal's cost is driven by raw material quality (like new versus recycled plastic), the complexity of its locking mechanism, and crucial security certifications. These factors determine its strength, reliability, and how well it protects your goods.

When I first started in quality control, my job was to break seals all day long. A pitfall I quickly learned to spot was how some manufacturers cut corners on raw materials. The same way you wouldn't use cheap sand in a house's foundation, using recycled plastic for a seal destined for extreme temperatures is asking for trouble. A small saving on materials can lead to a catastrophic failure down the line, and that's a lesson I've never forgotten. The choices made at the start define the final product's performance and price.

Key Cost Factors in Seal Manufacturing

| Component | Lower Cost Option | Higher Cost (and Higher Security) Option | Impact on You |

|---|---|---|---|

| Plastic Body | Recycled or mixed plastic | 100% new ABS Plastic | Recycled plastic can become brittle in extreme heat or cold, making it easier to break accidentally or intentionally. |

| Steel Pin/Cable | Low-grade steel | High-tensile, aircraft-grade steel | Weaker steel can be cut with simple tools, defeating the purpose of the seal entirely. |

| Marking | Hot-stamping | Laser engraving | Hot-stamped numbers can sometimes be rubbed off or altered. Laser engraving is permanent and clearly shows tampering. |

| Locking System | Simple, single-point mechanism | Complex, anti-spin, double-locking mechanism | A simple lock is easier to bypass. An advanced system provides much higher, more reliable security. |

Understanding these elements helps you ask smarter questions and see why a slightly higher price often means significantly better protection.

The Hidden Costs: Why a "Cheap" Seal Can Be Your Most Expensive Mistake?

Found a seal for a rock-bottom price? Be very careful. That appealingly low price often hides massive risks that can lead to huge financial losses down the road.

A "cheap" seal can lead directly to cargo theft, customs delays, angry customers, and expensive legal disputes. The cost of a single failed shipment will always be far greater than any savings you made on a few thousand seals. This is the most critical lesson in procurement.

I'll never forget a client who switched suppliers to save about $0.10 per seal. He was happy at first. Three months later, he called me in a panic. A container arrived with a broken seal, and a significant portion of the high-value electronics inside was gone. The pitfall he fell into was that his insurance claim was denied because he couldn't prove the seal wasn't defective. The "savings" of a few hundred dollars on seals ended up costing him over $50,000 in lost goods and, worse, a damaged relationship with his biggest customer. This story is not unique. The real cost is never just the price on the invoice.

Calculating Your True Cost

To avoid this trap, my approach now is to always think about the total cost. Here’s a simple way to frame it:

- Purchase Price: The price you pay per seal.

- Communication & Time Costs: How many emails does it take to get a clear answer? Your time is valuable.

- Risk Costs: What is the financial impact if a seal fails? This includes lost goods, fines, and legal fees.

- Reputation Costs: What is the long-term cost of a compromised shipment on your customer relationships?

A slightly more expensive seal from a reliable supplier drastically reduces all costs except the purchase price, making it the truly cost-effective choice.

Quality Markers: 4 Telltale Signs of a Superior Seal (That Don't Always Cost More)?

How can you spot a high-quality seal without being an industry expert? It's easier than you think. There are clear, visible signs that separate a reliable seal from a risky one.

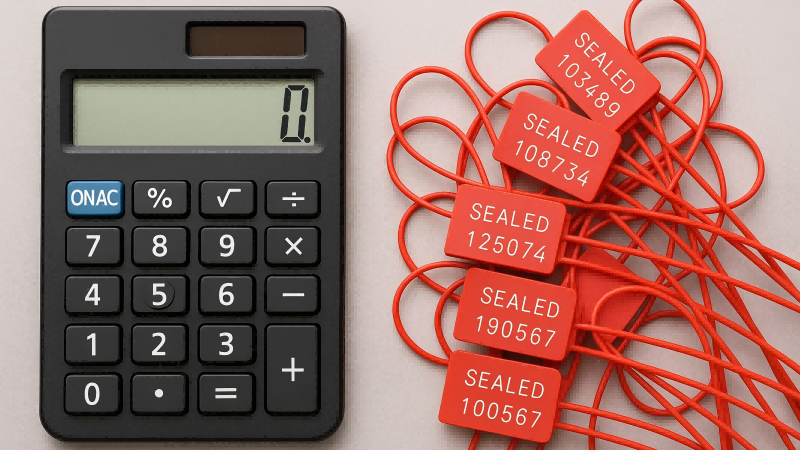

Look for clear, unique serial numbers; high-security certifications like ISO 17712; durable materials that show evidence of tampering; and a strong, non-replicable locking mechanism. These are the hallmarks of a trustworthy seal that will protect your cargo.

As a former QC inspector, my job was to find weaknesses. This taught me to spot quality—or the lack of it—very quickly. You don't need a lab; you just need to know what to look for. Paying attention to these four areas can save you from making an expensive mistake, and these features are often standard with any serious manufacturer, so they don't always add a huge premium.

- Unique & Legible Markings: A good seal has a unique serial number that is clearly laser-engraved. Laser engraving is permanent and cannot be altered without leaving obvious damage.

- International Standards Compliance: A serious supplier will have their high-security seals certified to ISO 17712. This standard proves the seal passed tough tests for strength and tamper-evidence. Always ask for the certificate.

- Material Integrity: Feel the seal. Does it feel solid or flimsy? A quality seal made from virgin ABS plastic feels robust. The steel pin on a bolt seal should be thick and strong. If it feels light, it's a red flag.

- Advanced Locking Design: When you click a bolt seal shut, it should make a solid sound. The pin should lock firmly. Some better seals have anti-spin features, meaning a thief can't just spin the seal with a drill to break it.

Strategic Sourcing: Unlocking Value by Working Directly with Factories?

Tired of dealing with middlemen who don't understand your security needs? Sourcing directly from the factory floor can completely change your experience, giving you more control and better value.

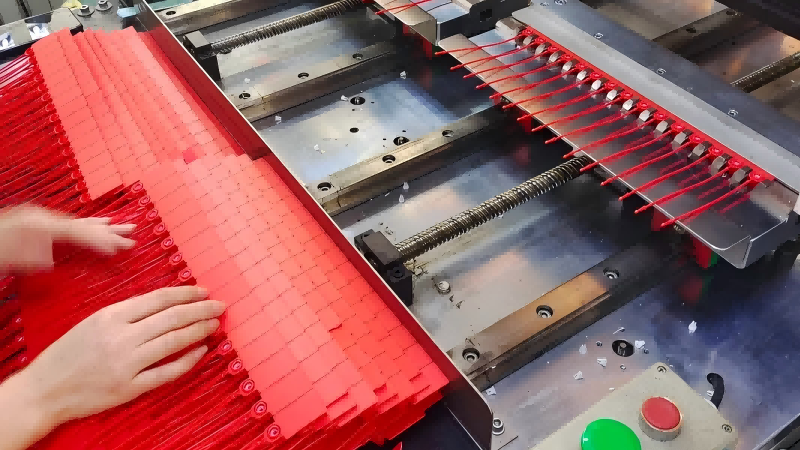

Working directly with a factory cuts out trader markups, massively improves communication, and allows for deep customization. This direct line ensures you get the right product, reducing errors, delays, and long-term costs.

I've seen the procurement process from both sides. A common frustration for importers is when communication is filtered through a trading company. Details get lost, and delays happen. My approach now is to always build a direct line of communication. When a client speaks with the people who actually make the product, they get clear answers. A request for a custom color or barcode format goes straight to the technical team. This eliminates the misunderstandings that cost time and money. It is a faster, safer, and more cost-effective way to buy.

Sourcing via Trader vs. Direct from Factory

| Aspect | Sourcing via Trader | Sourcing Direct from Factory |

|---|---|---|

| Price | Includes trader's markup. | Factory price, no middleman cost. |

| Communication | Indirect and often slow. | Direct, fast, and clear. |

| Customization | Limited and prone to errors. | Flexible, with expert guidance. |

| Problem Solving | Slow; trader is a go-between. | Fast; you talk to the source. |

| Expertise | General trading knowledge. | Deep product and security expertise. |

The table makes it clear: if you want value and reliability, building a relationship with a factory is the strategic choice.

Is Your Supplier a Partner or Just a Vendor?

Does your supplier just take your order? Or do they actively work to solve your security problems? This difference is critical for your success.

A true partner understands your business, offers expert advice, communicates proactively, and takes responsibility. They focus on minimizing your total cost, not just on making a single sale.

In my career, I've learned the most successful importers don't just look for suppliers; they build partnerships. A vendor sells you a product. A partner invests in your success. A vendor disappears after payment. A partner checks in to ensure the shipment arrived safely. This proactive service is what truly defines value. It’s the difference between buying a commodity and investing in a security solution that strengthens your chain of custody and gives you peace of mind.

Your Partner-Vendor Checklist

Ask yourself these questions about your current supplier:

- Do they ask about my cargo and shipping routes before recommending a seal?

- Can they clearly explain why one seal type is better for my needs?

- Do they provide ISO certificates without me having to chase them?

- When there is a problem, are they responsive and helpful?

- Do they offer advice on best practices for seal application and inspection?

If you answered "no" to most of these, you have a vendor. And that is likely costing you money in hidden ways.

Conclusion

True cost-effectiveness isn't about the lowest price tag. It's about minimizing your total cost and risk by choosing a quality product and a reliable, expert partner.

Get a Strategic Security Solution from ProtegoSeal

To protect your business from costly disputes and hidden risks, ProtegoSeal offers more than just seals—we provide strategic security solutions. Our approach focuses on lowering your total cost of ownership, giving you the reliable products and expert partnership needed to secure your supply chain. Contact us for a strategic consultation or to request a free sample.