Finding a great security seal supplier in China feels like a huge challenge. A bad choice can lead to delays, poor quality, and lost profits, making the whole process stressful.

To choose the best security seal supplier, first, assess if they are a factory or a trading company. Then, evaluate their factory size, production capabilities in key industrial zones like Guangdong, and responsiveness. A good partner offers quality products and excellent communication.

Over my 15 years in this industry, I've seen many buyers make the same mistakes. They focus only on the price on the quotation sheet. But the real cost of a bad supplier shows up later in production delays and quality issues. The secret isn't just finding the cheapest price; it's finding the right partner. I'm going to walk you through the exact steps I use to vet suppliers, so you can make your next sourcing decision with total confidence.

The First Big Decision: Direct Factory vs. Trading Company?

You get two quotes for the same product, but one is much cheaper. Is it a factory price or just a trader cutting corners? Making the wrong choice here can cost you dearly.

For security seals, always try to work directly with a factory. This gives you better prices, direct communication for customization, and more control over quality. Trading companies add a markup and can create communication delays, especially on technical issues.

This is one of the most fundamental choices you’ll make. A trading company might seem convenient, especially if you want to buy many different products. However, for a specialized product like security seals, the disadvantages are significant. When you have a technical question or need a custom print, the trader has to relay your message to the factory, and the answer comes back through them. Information gets lost, and the process is slow.

Working directly with a factory puts you in control. You can speak with the people who are actually making your product. This is crucial for quality control and getting production updates. The price will also be lower because there is no middleman.

Here’s a quick comparison to help you decide:

| Factor | Direct Factory | Trading Company |

|---|---|---|

| Pricing | Lower, direct pricing | Higher (includes their profit margin) |

| Communication | Direct, faster, more technical | Indirect, slower, risk of miscommunication |

| Customization | Excellent, direct access to engineers | Limited, depends on their factory relationship |

| Quality Control | You have more influence and visibility | You rely on the trader to manage QC |

| Product Range | Specialized in their product line | Wide variety from multiple factories |

Right-Sizing Your Partner: Why Factory Scale Matters for Your Business?

You've found some factories, but one is massive and another is a small workshop. Does a bigger factory mean better quality, or will your order get lost in their huge production schedule?

Factory size directly impacts mold availability, lead times, and flexibility. A large factory offers more mold options, saving you money, but may have long lead times. A medium-sized factory often provides the best balance of speed, flexibility, and quality.

In my experience, blindly choosing the biggest factory is not always the best strategy. The right size depends on your needs.

Large Factories

These giants might have 70 to 100 sets of molds. This is a huge advantage because it means they likely have a design very close to what you need, saving you the high cost of creating a new mold. However, because they have so many large clients, your order will be put in a queue. Waiting for machine time can lead to very long delivery times.

Medium Factories

This is often the sweet spot for many buyers. A medium-sized factory is more flexible. Since they have fewer massive orders to schedule, they can often start production on your order much faster. Their delivery times can be a major competitive advantage. If the factory has strong quality control systems and good service, this is an excellent choice.

Small Factories

I generally advise caution here. Small factories have very few molds, so you'll likely have to pay for a new one. More importantly, their quality control systems may not be as robust, making the final product a bit of a gamble.

Deep Dive: Assessing Core Capabilities from Production to Certification?

A supplier's website looks professional, and they sent you a great-looking catalog. But how can you know if their real production capabilities match their marketing promises?

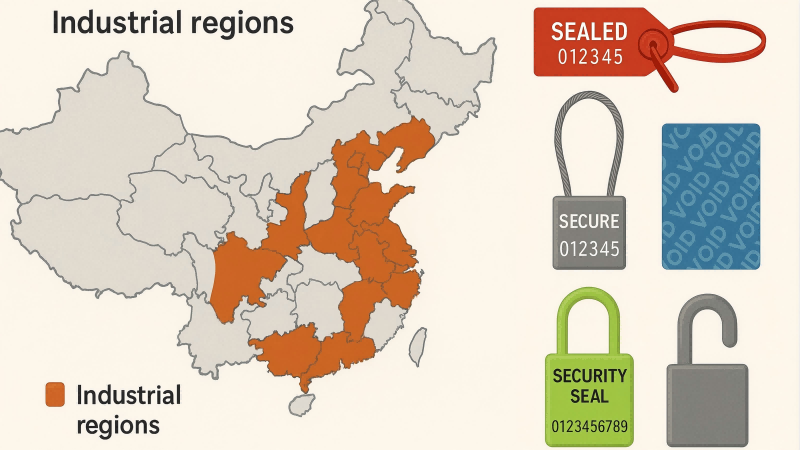

Look for proof of their core capabilities. Check for key certifications like ISO 9001, assess their location within China’s industrial clusters, and ask about their production technology. For example, top plastic seal factories are often in Guangdong province due to its advanced automation.

You need to investigate a few key areas to understand a supplier's true strength.

First, location matters. The security seal industry in China is concentrated in a few regions. For plastic seals, the best suppliers are in the south, in Guangdong province (cities like Guangzhou, Shenzhen, and Dongguan). This area has highly automated factories and skilled labor. Dongguan is a world-famous hub for precision molds, which means suppliers there produce higher-quality products.

Second, understand the product type. Plastic seals benefit from automation and advanced molding, found in the south. Metal seals, like bolt seals and cable seals, are more labor-intensive because they require manual assembly. This makes them more expensive.

Third, ask for certifications. At a minimum, a professional factory should have an ISO 9001 certificate, which shows they have a quality management system in place. If you are buying high-security seals for international shipping, they absolutely must have an ISO 17712 certificate for those specific products. Don't just take their word for it; ask to see the certificate.

Beyond the Product: Spotting Red Flags in Communication and Service?

You sent a detailed inquiry three days ago, and all you got back was a one-line email with a price. Is this a sign of how they'll handle your actual order?

Yes, it is. Early communication is the best indicator of future service. A good partner responds quickly, answers your questions professionally, and offers helpful advice. Slow, unprofessional, or vague communication before you have even paid is a massive red flag.

The product itself is only half of the equation. The service you receive is just as important. A cheap price means nothing if your shipment is delayed because the sales representative forgot to confirm a detail with you.

Here’s a personal tip that has saved my clients a lot of trouble: the quality of the salesperson matters. I have seen great factories with terrible salespeople who are unresponsive and unhelpful. If you are trying to work with a factory but the salesperson assigned to you is not meeting your needs, do not give up on the factory. Ask to speak to their manager and request a different sales contact.

A good salesperson should feel like a partner. They should be:

- Responsive: Answering your emails within 24 hours.

- Knowledgeable: Able to answer technical questions or quickly find the answer.

- Proactive: Offering suggestions to improve your product or save you money.

- Clear: Communicating in clear, direct language.

If your contact shows none of these qualities, you are likely heading for problems.

Your Final Vetting Tool: The Ultimate Pre-Contract Question Checklist?

You've narrowed your choice down to one or two suppliers. They seem perfect, but you want to be 100% sure before signing a contract and sending money.

Before you commit, use a final checklist to get critical details in writing. Ask specific questions about quality control for your batch, production lead times, mold ownership, and how they handle potential problems. This eliminates ambiguity and protects your investment.

Getting clear, written answers to these final questions will prevent major headaches later on. Here is the checklist I always recommend my clients use before they sign a purchase order:

- Quality Control: "What specific quality checks will you perform on my batch of seals, and can I get a copy of the QC report before shipment?"

- Lead Time: "What is the confirmed production lead time after my artwork is approved and the deposit is paid?"

- Molds & Tooling: "Is there an existing mold for my design? If a new mold is needed, who owns it after I pay the fee?"

- Communication: "Who will be my single point of contact during the entire production process?"

- Problem Resolution: "What is your process if we discover a quality defect after the goods arrive?"

- Samples: "Can you send a few pre-production samples from my actual batch for final approval before you start mass production?"

A professional and confident supplier will have no problem answering these questions clearly.

Conclusion

Choosing a Chinese supplier requires checking their core capabilities, size, and service, not just the price. Use this guide to find a true partner who will help secure your supply chain.

Contact ProtegoSeal for Chinese Supplier Expertise

Looking for reliable Chinese suppliers? ProtegoSeal offers expert guidance based on our established relationships with verified Chinese security seal manufacturers. Our team's local experience ensures smooth supplier selection and quality procurement.

Contact us at +86 15322882223 or info@protegoseal.com to leverage our Chinese sourcing expertise for your business needs.