Choosing the wrong security seal can leave your valuable cargo exposed. This simple decision can mean the difference between a secure delivery and a significant loss.

The best high-security seal depends on your needs. For standard container doors requiring maximum strength and a foolproof application, a bolt seal is the top choice. For irregular locking points or when flexibility is needed, a cable seal is the better, more versatile solution.

The decision between a bolt seal and a cable seal seems straightforward, but it goes much deeper than it looks. In my experience, I've seen that customers are really choosing between two different security philosophies: rigid, standardized security or flexible, adaptive security. Understanding this key difference is the first step to making the right choice, ensuring your cargo is protected effectively and efficiently. Let's dive into the specifics so you can see which approach is right for your business.

What is the difference between a cable seal and a bolt seal?

It can be confusing to look at these two seals. A bolt seal looks very strong, but a cable seal seems like it can be used anywhere. Choosing the wrong one can be a costly mistake.

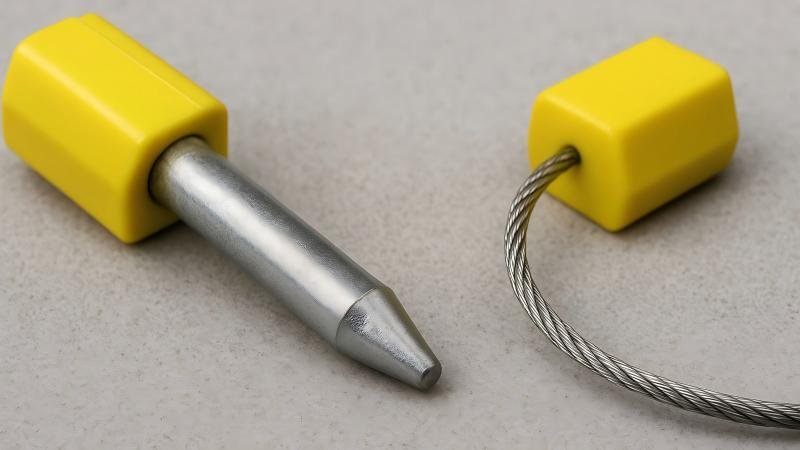

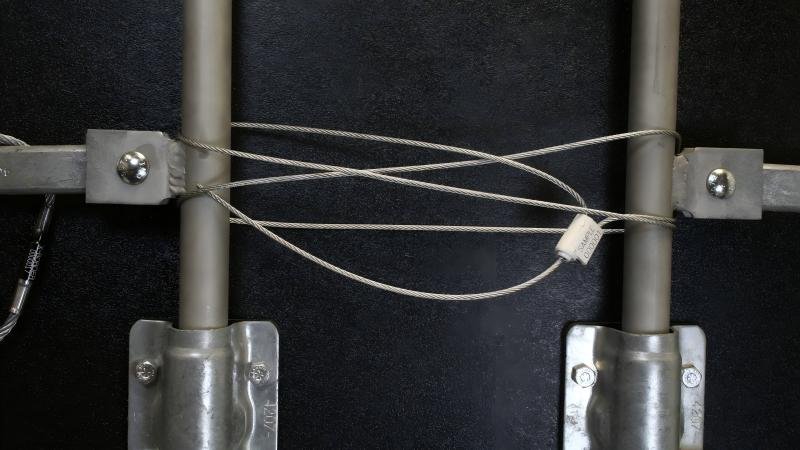

The main difference is rigidity versus flexibility. A bolt seal is a fixed-length, rigid steel pin that locks into a barrel, designed for standard holes. A cable seal uses a variable-length, flexible steel wire that can secure diverse or misaligned locking points. This core design difference dictates their best uses.

When I talk with clients, I often ask them to think about their security process. Do you want something that is impossible to use incorrectly, or do you need something that can solve unusual problems?

A bolt seal represents what I call "unambiguous security." It’s made of a solid steel pin and a locking body. When you push the pin into the body, it makes a loud "click." That sound means it is locked. There is no in-between state. It is either locked or it is not. This removes human error.

A cable seal offers "adaptive security." It has a long, flexible steel aircraft cable. You can pull it tight to any length you need. This flexibility is great, but it requires your team to be trained to pull it tight enough. The security of the seal depends on the person applying it.

Here is a simple breakdown:

| Feature | Bolt Seal | Cable Seal |

|---|---|---|

| Structure | Rigid Pin & Barrel | Flexible Steel Cable |

| Application | Standardized Holes (e.g., ISO Containers) | Irregular or Multiple Locking Points |

| Human Factor | Low (Foolproof) | Medium (Requires User Judgment) |

| Tamper Evidence | Pin must be cut; shows clear marks | Cable frays when cut; very obvious |

| Cost | Generally Higher | Generally More Cost-Effective |

When to Use a Bolt Seal: Top Applications and Scenarios?

Are you worried about brute-force attacks on your shipping containers? A weak seal is an open invitation for thieves. You need a seal that acts as a strong visual and physical deterrent.

Use a bolt seal for high-value cargo in standard shipping containers, especially for cross-border shipments that require ISO 17712 compliance. Its tough, rigid design is perfect for the standard hasps on container doors, offering maximum strength against physical attacks and tampering.

The number one use for a bolt seal is on an intermodal shipping container. The reasons are simple: standardization and strength. Millions of containers travel the world, and their locking mechanisms are the same. A bolt seal is designed perfectly for them. Anyone, anywhere in the world, can quickly lock it and hear the "click" that confirms it's secure. There is no guesswork.

This "foolproof" design is critical for large logistics operations. It simplifies training and reduces the risk of an employee accidentally leaving a container unlocked. From a security standpoint, a high-security bolt seal requires large, powerful bolt cutters to remove. A thief can't just break it off with a hammer. This strength makes it a powerful deterrent. If you are shipping high-value goods like electronics or pharmaceuticals internationally, a certified bolt seal is the professional standard.

When to Use a Cable Seal: Best for Irregular or Multi-Point Locking?

Do you need to lock a truck with doors that don't line up perfectly? Or maybe secure a valve on a tanker? A rigid bolt seal simply won't work in these cases.

Cable seals are the perfect solution for situations where bolt seals can't be used. This includes trailer doors, rail cars, tanker truck valves, and even securing multiple items together. Their adjustable, flexible cable can navigate odd openings and pull everything tight for a secure fit.

Think about the real-world situations my clients face. One might have a transport truck where the doors have become slightly misaligned over time. A bolt seal won't fit through the hasps. A cable seal can easily loop through and pull them tight. Another client might need to secure the hatches on a liquid tanker. Again, a cable seal is the only practical option.

The key benefit is adaptability. You decide how long or short the loop is. Plus, cable seals offer great tamper evidence. When cut, the aircraft-grade steel cable frays and cannot be glued or pushed back together. It’s immediately obvious that the seal has been compromised. Cable seals also come in various diameters, from a thin 1.8mm cable to a very thick 5.0mm cable. This allows you to choose the right balance of security and cost for your specific shipment.

What Does ISO 17712 Certification Mean for Your Cargo?

You probably see "ISO certified" on products all the time, but what does it really mean for security seals? Shipping internationally without the right certification can cause big problems, including fines and long delays at customs.

ISO 17712 is the international standard that specifies the requirements for mechanical freight container seals. It proves a seal has passed intense tests for strength and tamper evidence. Seals rated as "H" for High Security are mandatory for international shipments under programs like C-TPAT in the USA.

This standard is your assurance of quality and security. It is not just a marketing term. A manufacturer must have their security procedures audited, and the seals themselves are sent to an independent lab for testing. They are pulled, crushed, and sheared to ensure they meet a specific level of strength.

There are three classes:

- "I" for Indicative: Provides tamper evidence but is easy to remove.

- "S" for Security: Offers limited resistance to intrusion.

- "H" for High Security: The toughest category, designed to be removed only with large cutters.

For any business shipping cargo internationally, you should only consider "H" class seals. Using a non-certified seal is a huge risk. A customs agent in the US or Europe might flag your container for a full inspection, simply because the seal is not compliant. This costs you time and money. Both heavy-duty bolt seals and thick cable seals (typically 3.5mm and above) can achieve this high-security rating.

Making the Right Choice: Key Questions to Ask Before You Buy?

Choosing a seal based only on its price is a common but dangerous mistake. On the other hand, overspending on security you don't need is bad for your bottom line. How do you find the right balance?

Before you buy, ask yourself four key questions: 1) What am I sealing? 2) How valuable are the goods inside? 3) Do I need ISO 17712 certification for customs? 4) What does our internal security procedure require? Answering these will point you to the perfect seal.

Let's walk through these questions. Your answers will make the choice clear.

What am I sealing? Is it a standard container door with perfectly aligned ISO-compliant lock holes? A bolt seal is designed for this. Is it a truck trailer, a rail car, or a piece of equipment with awkward locking points? You need the flexibility of a cable seal.

What is the value of the goods? If you are shipping a container of high-value electronics, the small extra cost for a top-of-the-line high-security bolt seal is a wise investment. If you are shipping lower-value bulk materials, a strong, certified cable seal may provide perfectly adequate security for a better price.

Do I need customs certification? If your shipment will cross international borders, especially into the United States, the answer is almost always yes. You need an ISO 17712 "H" rated seal to comply with C-TPAT. Don't take chances here.

What is my security procedure? This is the "philosophy" question. Do you have a large team and need a simple, foolproof locking process? The bolt seal is your best bet. Or do you have specific, varied needs where a trained operator can use a flexible tool effectively? The cable seal is the answer.

Conclusion

Ultimately, choosing between a bolt seal and a cable seal is about matching the right tool to the right job. You are deciding between the rigid, foolproof security of a bolt seal and the adaptive, flexible security of a cable seal.

If you have more questions or need a professional opinion on your specific security needs, don't hesitate to reach out to an industry expert.

Ready to Secure Your Cargo with the Right Seal?

Choosing the right seal is a critical decision, and we understand that every shipment has unique requirements. If you still have questions after reading this guide, or if you'd like expert advice tailored to your specific business, the specialist team at ProtegoSeal is ready to help.

We're more than just a supplier; we're your security partners. We will work with you to analyze your cargo value, shipping routes, and operational procedures to recommend the most robust and cost-effective security seal solution.

Contact us today for a free expert consultation or to request a quote.