When buying security seals in bulk, price is important, but quality is more important. Cutting corners on quality will bring huge losses to the company! Therefore, I also need to have a certain understanding of the materials used by the security seal manufacturer before purchasing.

The material a security seal is made of determines its strength, durability, and resistance to tampering. Whether you are in pharmaceuticals, logistics, or manufacturing, understanding seal materials is the first step to effectively protecting your assets. This blog will focus on the five most commonly used materials and their corresponding impacts and cases.

The five most common security seal materials

1. Polypropylene (PP)

Polypropylene is a lightweight and cost-effective plastic widely used in security seals. It's resistant to chemicals and UV degradation, making it ideal for general logistics, agriculture, and retail packaging.

Pros and Cons of Polypropylene Seals

| Pros | Cons |

|---|---|

| Low cost | Moderate strength |

| UV and chemical resistant | Less tamper-evident than metals |

| Easy to customize | Limited durability in extreme conditions |

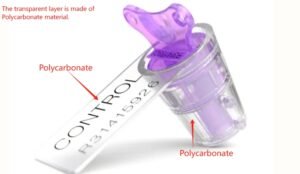

2. Polycarbonate (PC)

Polycarbonate seals are known for their high impact resistance and clarity. They’re ideal for applications needing transparency, such as utility meters, and withstand UV exposure and weathering exceptionally well.

Comparison: Polycarbonate vs Polypropylene

| Property | Polycarbonate | Polypropylene |

|---|---|---|

| Durability | High | Moderate |

| UV Resistance | Excellent | Good |

| Cost | Higher | Lower |

| Tamper Evidence | High | Moderate |

3. Nylon

Nylon offers excellent mechanical strength and flexibility, performing well under low temperatures, making it suitable for food safety and cold chain logistics. According to MaterialDataCenter.com, Nylon 6 has a tensile strength of up to 90 MPa and withstands temperatures as low as -40°C.

4. Metal (Steel, Aluminum)

Metal security seals, particularly steel bolt seals, are commonly used in international shipping and high-security logistics. They are tamper-evident and comply with ISO 17712 high-security standards.

Steel vs. Aluminum Seals

| Feature | Steel | Aluminum |

|---|---|---|

| Strength | Very High | Moderate |

| Corrosion Resistance | Needs Coating | High |

| Weight | Heavy | Light |

| Price | High | Moderate |

5. Biodegradable Plastics (Eco-friendly Options)

Eco-conscious buyers are now considering biodegradable plastics made from starch or PLA. Though they lack the durability of other materials, they’re ideal for short-term, low-risk applications such as event tagging or waste segregation.

Data Source: EPA reports that typical biodegradable plastics degrade within 180 days in composting environments, compared to 500+ years for conventional plastic.

How Materials Influence Seal Performance

The material composition directly affects a seal's tamper resistance, environmental tolerance, and operational cost. Some seals are optimized for extreme temperatures, while others are chosen for their biodegradability or tensile strength. Therefore, aligning material characteristics with intended application is critical.

Comparison table of 5 kinds of materials

| Material | Durability | Cost | Eco-Friendly | Common Applications |

|---|---|---|---|---|

| Polypropylene | Moderate | Low | Low | Logistics, Retail |

| Polycarbonate | High | High | Low | Utilities, Security |

| Nylon | High | Medium | Low | Cold Chain, Food |

| Steel/Aluminum | Very High | High | Low | Cargo, Customs |

| Biodegradable | Low | Moderate | High | Events, Short-Term Use |

Environmental Considerations

Materials like steel and plastic have a significant carbon footprint, while biodegradable alternatives offer greener options. Polypropylene and nylon can be recycled but require specialized facilities. Understanding these factors helps companies align with ESG goals.

Cost Analysis: Upfront vs Lifecycle Cost

Though polypropylene seals have lower upfront costs, materials like nylon or metal may offer better value over time due to reduced failure rates and less frequent replacement. Consider total cost of ownership, including installation, monitoring, and disposal.

Tips for Choosing the Right Material

- Industry: Food & pharma may prioritize hygiene and flexibility (Nylon); cargo logistics may need tamper-evident strength (Metal).

- Environment: For high-humidity or UV exposure, use polycarbonate or coated metals.

- Budget: For bulk, short-term use, polypropylene or biodegradable seals may be ideal.

Case Study: Choosing the Right Material for Cold Chain Logistics

Challenge: A food distributor experienced frequent seal failures in freezing temperatures.

Solution: Switched from polypropylene to nylon seals.

Result: Reported 40% reduction in seal breakage, enhanced product integrity during transport.

Conclusion: Making an Informed Purchase Decision

From polypropylene's cost-effectiveness to metal's unbeatable strength, each material offers unique advantages. Consider your industry, environmental factors, and compliance needs when choosing a seal. A well-chosen seal material ensures not only security but operational efficiency and regulatory peace of mind.

FAQs

- What is the strongest material for security seals?

Steel is the strongest and most tamper-evident option, especially for shipping containers. - Are biodegradable seals reliable?

Yes, for short-term applications. They are less durable but ideal for temporary tagging. - Can one seal type serve all industries?

No. Each industry has unique requirements for strength, compliance, or environmental tolerance. - How do I know if a seal meets compliance standards?

Look for ISO 17712, C-TPAT, or industry-specific certifications from reputable suppliers.

Contact Us

If you're looking for competitive prices with guaranteed quality, contact us! ProtegoSeal has a comprehensive production process and strict quality control, backed by over fourteen years of industry experience, offering you high-quality security seal solutions.