Security and integrity are critical to the logistics, food and pharmaceutical industries. Any tampering, contamination or theft can result in significant financial losses, regulatory non-compliance and reputational damage. One of the simplest but most effective solutions to these challenges is the use of plastic seals. These cost-effective security devices help organizations prevent unauthorized access, enhance traceability, and ensure regulatory compliance

However, some companies overlook the importance of tamper-proof solutions, leading to disastrous consequences. In this article, we explore how plastic seals provide critical benefits to three major industries and what happens when they are not used effectively.

What Are Plastic Seals and How Do They Work?

Plastic seals are single-use security devices designed to prevent unauthorized access and provide evidence of tampering. They are commonly used to seal cargo containers, food packages, and pharmaceutical products.

Types of Plastic Seals

- Pull-tight seals: Adjustable-length seals for securing different container sizes.

- Fixed-length seals: Seals with a pre-determined length, often used for standardized security applications.

- Breakaway seals: Easily broken by hand, used for quick-access applications.

- Cable seals: Stronger seals that provide high security for valuable goods.

These seals offer a unique identification number, making it easy to track shipments and detect tampering.

How Plastic Seals Benefit the Logistics Industry

Ensuring Cargo Security and Preventing Theft

One of the biggest concerns in logistics is cargo theft. Plastic seals act as a deterrent against unauthorized access and provide visible evidence if someone attempts to tamper with a shipment. This helps reduce losses and ensures customers receive goods in their original condition.

Enhancing Regulatory Compliance

Governments and international organizations enforce strict transportation security regulations. Many customs agencies require cargo shipments to be sealed with ISO-certified plastic seals to ensure goods are not tampered with before reaching their destination.

✅ Success Example: Compliance with Customs Regulations

A global logistics provider successfully reduced customs clearance delays by using high-security plastic seals with unique serial numbers. This not only sped up border crossings but also reduced unnecessary inspections, saving time and operational costs.

Cost-Effectiveness and Operational Efficiency

Plastic seals are lightweight, easy to apply, and cost-effective compared to metal seals or electronic tracking systems. They streamline logistics operations by ensuring shipments remain secure from origin to destination without requiring expensive security solutions.

⚠️ Pitfall: Over-Reliance on Paper-Based Security

Some companies still rely on manual documentation instead of using plastic seals. However, paper logs can be forged or misplaced, leading to security breaches. Implementing plastic seals with digital tracking enhances security while reducing paperwork errors.

How Plastic Seals Ensure Food Safety and Quality

Preventing Contamination and Tampering

Food products must be transported and stored under strict hygiene conditions. Plastic seals help prevent contamination by ensuring that food containers, storage units, and delivery trucks remain sealed until they reach their intended recipient.

Failure Case: Food Theft During Delivery

Plastic seals are crucial in the takeaway food delivery industry to ensure food remains secure during transit. However, food theft by delivery drivers is a common issue, with nearly 30% of drivers admitting to snacking on the food they deliver (US Foods study).

Food theft occurs due to two main reasons:

Tempting Smells: Hungry drivers or those poorly paid may be tempted to steal food.

Insecure Packaging: Poorly sealed packaging makes it easier for drivers to take food without detection.

Meeting Food Safety Regulations

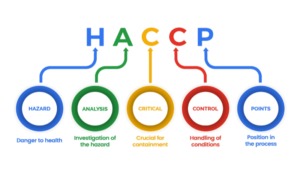

Regulatory bodies such as the FDA, HACCP, and ISO 22000 require strict measures to prevent food adulteration. Plastic seals ensure compliance by providing evidence that food packaging and storage remain intact throughout the supply chain.

✅ Success Example: Using Seals to Comply with HACCP Standards

A frozen food supplier successfully passed an international food safety audit by implementing plastic seals on all cold storage units and delivery trucks. These seals ensured that products were kept at the required temperatures, reducing the risk of spoilage and bacterial growth.

Enhancing Supply Chain Transparency

Plastic seals with serial numbers or QR codes enable better tracking and traceability. If an issue arises, companies can quickly identify the affected batch and take corrective actions.

⚠️ Pitfall: Lack of Traceability Leading to Widespread Product Recalls

In a recent foodborne illness outbreak, a fast-food chain had to recall contaminated vegetables but struggled to track the affected shipments. Without proper seals and tracking systems, the company spent weeks identifying the source, leading to extended financial and reputational damage.

With food safety covered, let’s now examine how plastic seals benefit the pharmaceutical sector.

How plastic seals ensure the safety of medicines

The safety of medicines is of utmost importance, especially vaccines, prescription drugs and other sensitive drugs. During production, raw materials to finished products need to be strictly controlled to ensure that the products remain intact. Plastic seals can be used at key steps to ensure the safety of the pharmaceutical process. The following examples perfectly illustrate the benefits of plastic seals.

1. Compliance with Regulations

Pharmaceutical companies must follow strict regulations from bodies like the FDA and EMA. Plastic seals help maintain packaging integrity and prevent tampering, ensuring products meet safety and legal standards while reducing the risk of violations.

2. Brand Integrity

A good brand reputation is vital to pharmaceutical companies. Any tampering that results in contamination of the drug will damage the brand. Plastic seals protect the integrity of the product, ensuring that it reaches the consumer in the same condition as when it left the factory, thereby earning the consumer's trust.

3. Reducing the Risk of Counterfeiting

Counterfeit medicines are a global problem. Plastic seals with unique identifiers, barcodes or serial numbers can be an effective anti-counterfeiting measure, allowing consumers to verify authenticity and prevent counterfeit medicines from entering the market and harming public health.

Contact Us

ProtegoSeal is a trusted manufacturer specializing in the design and production of high-quality security seal solutions to protect goods and prevent tampering, with top-tier manufacturing in China. If you’re looking for convenient and secure plastic seals, feel free to contact us today.