- +86 15322882223

- info@protegoseal.com

Delivering high-quality, tamper-evident plastic seals designed for reliability and precision. Partner with a global manufacturer committed to helping your business succeed.

Protegoseal Custom Plastic Seals offers a secure solution for safeguarding your goods, ensuring that any unauthorized access is immediately visible. Our seals are designed to meet the stringent demands of various industries, providing a reliable tamper-evident mechanism that protects your valuable assets.

With our custom plastic seals, you can enhance your brand’s trustworthiness and strengthen customer loyalty through our proven security solutions. We offer extensive customization services to meet your specific needs.

Create a lasting impression with custom plastic seals designed to reflect your brand. Our solutions ensure security and elevate your identity—sealing trust with every shipment.

Match your brand with a wide range of customizable colour options, ensuring your plastic seals stand out while maintaining security.

You can choose from premium materials, including polypropylene, ABS plastic, and nylon, engineered for durability in any environment.

Enhance traceability and branding with laser-engraved logos, barcodes, or text tailored to your needs.

Add unique serialized numbers to every seal for accountability and security, making tracking seamless and precise.

Incorporate advanced tamper-evident mechanisms like no-spin designs or heat-sensitive coatings for added security.

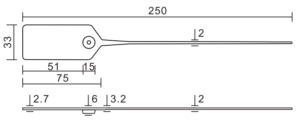

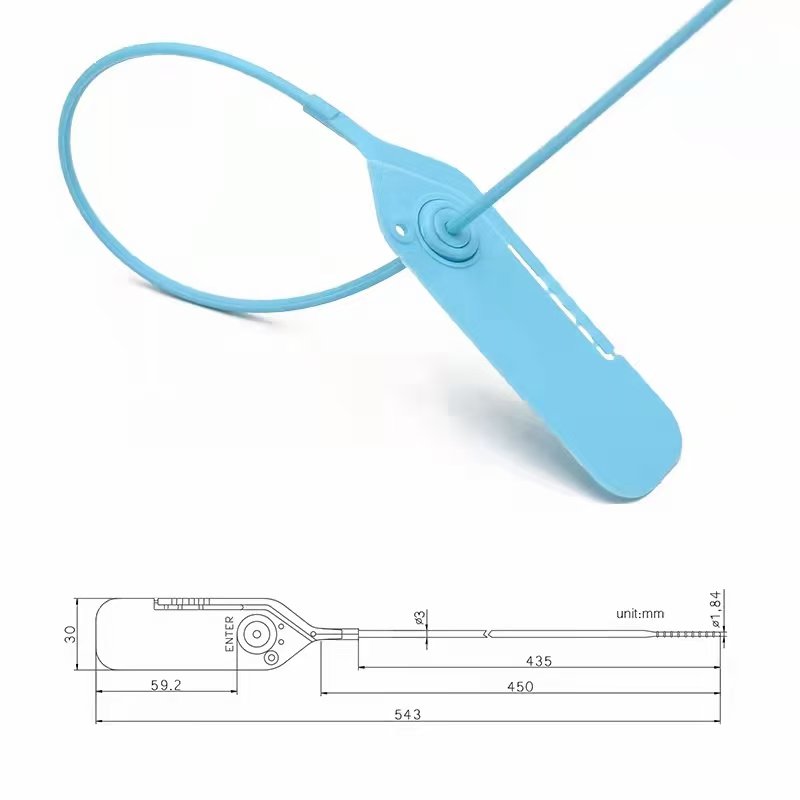

| Product | Structure diagram | Measurements |

|---|---|---|

|  | Flag 51 x 33 mm. Total length 250mm Tensile strength 247N |

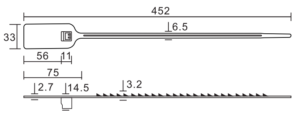

|  | Flag 56x 33 mm. Total length 452mm Tensile strength 256N |

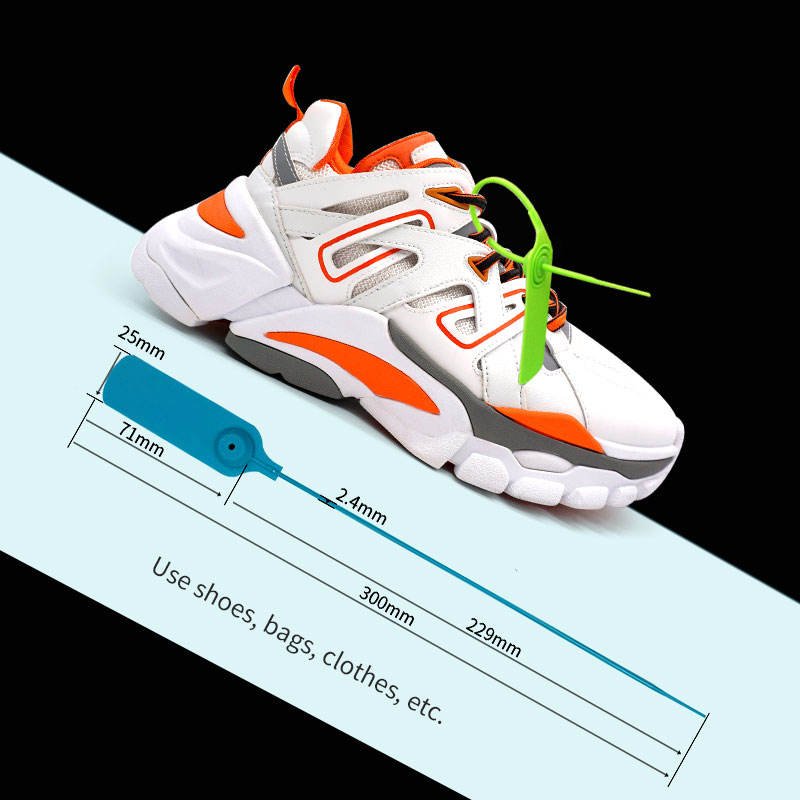

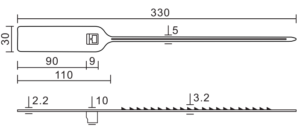

|  | Flag 90x 30 mm. Total length 330mm Tensile strength 229N |

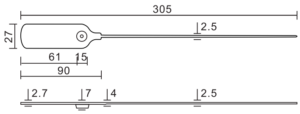

|  | Flag 61x 27 mm. Total length 452mm Tensile strength 259N |

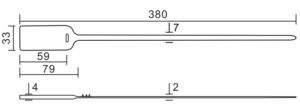

|  | Flag 59x 33 mm. Total length 380mm Tensile strength 283N |

The sizes shown are our most popular, but we couldn’t list them all. If you don’t see the size you need, please inquire, and we’ll help you find the perfect fit.

Select the Appropriate Seal

Choose a plastic seal that fits your application based on size, strength, and environmental conditions.

Insert the Seal

Thread the seal’s tail through the designated locking mechanism on the item you wish to secure.

Lock the Seal

Pull the tail through the locking chamber until the desired tightness is achieved. Ensure it is securely fastened but not over-tightened to avoid damage.

Understand the cost structure of plastic seals with precise pricing details. Learn how material selection, design complexity, and order volume influence overall costs

Polypropylene: $0.05–$0.08 per seal – Cost-effective and suitable for standard applications.

Nylon: $0.10–$0.15 per seal – Ideal for high-durability requirements and extreme conditions.

ABS Plastic: $0.12–$0.18 per seal – Offers enhanced strength and tamper resistance for critical security needs.

Standard Seals: $0.05–$0.10 per seal – Basic functionality for general use.

Customized Seals: $0.15–$0.25 per seal – Features like laser-engraved logos, serial numbers, and tamper-evident mechanisms increase security.

1,000–5,000 units: $0.20 per seal – Ideal for small to medium-scale requirements.

10,000–50,000 units: $0.12 per seal – Significant savings with bulk orders.

100,000+ units: $0.08 per seal – Best value for large-scale operations.

Our transparent pricing structure helps you plan effectively, guaranteeing premium-quality seals at competitive rates for every application.

From selecting premium materials to precision manufacturing and rigorous quality checks, every step is designed to deliver durable, tamper-evident seals that meet your unique requirements.

Protect your goods with premium plastic seals designed for versatile applications. From securing shipments to enhancing traceability, our seals offer reliable tamper evidence.

Typically, custom orders are fulfilled within 1-3 weeks.

The lead time depends on the size and customization of the order.

Our customized plastic seals start at 1,000 units, but if you purchase a standard product, there are no MOQ requirements.

Our seals undergo stringent testing, including tensile strength, dimensional accuracy, and environmental durability tests.

Yes, submit your request through the form, and we will respond within 1 business day to arrange the shipment of your free sample.

Our plastic seals are ISO 9001 certified and comply with REACH and RoHS regulations.

We provide full customization options, including laser-engraved logos, barcodes, unique serial numbers, and specific colours to match your branding or operational requirements.

We use high-grade materials like polycarbonate and stainless steel, add UV stabilizers and test for temperature and chemical resistance.

WhatsApp us

Free standard sample can be provided for your evaluation according to your requirements.