It is hard to imagine the risk of a patient receiving contaminated medication or using a compromised device. In healthcare, "safety" isn't just about labels; it's about physical control.

Mechanical security seals—specifically plastic seals, meter seals, and padlock seals—are the physical guardians of the medical supply chain. Unlike stickers, these devices physically lock containers, crash carts, and valves, ensuring that equipment is sterile, drugs are accounted for, and unauthorized access is physically prevented.

When we talk about "tamper-evident seals" in my industry, people often think of sticky tape. But in the gritty reality of hospital logistics and pharmaceutical transport, tape isn't enough. We are talking about mechanical seals. These are the plastic loops locking a hazardous waste bag, the padlock seals securing a narcotics cabinet, or the meter seals ensuring an oxygen regulator hasn't been tweaked. My insight here is simple: Mechanical seals provide a dual function that labels cannot—they offer both 'evidence' of tampering and a 'physical deterrent' to access. A label can be peeled; a plastic seal must be broken. This intentional act of breaking creates a clear, undeniable "Go/No-Go" signal for medical staff, which is critical when milliseconds count in an emergency.

Types of Mechanical Seals: Beyond the Sticker

In healthcare, different threats require different locks. A seal meant for a heavy shipping crate is useless on a delicate medical kit. Understanding the specific mechanical differences is key to operational safety.

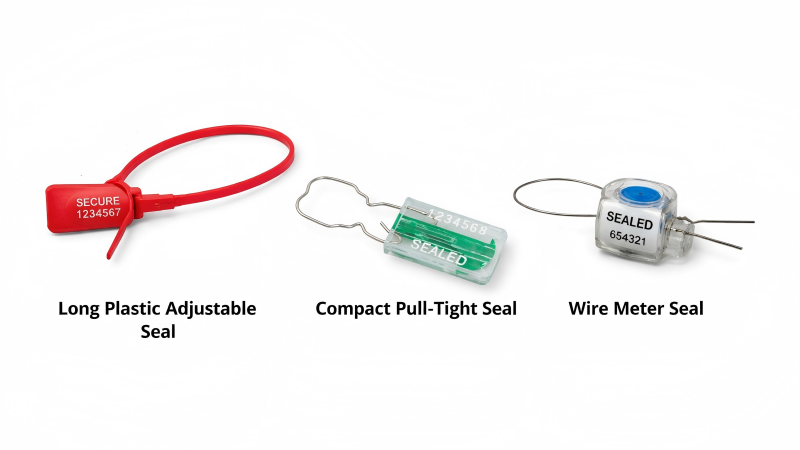

The healthcare industry primarily relies on three mechanical forms: Pull-Tight Plastic Seals for variable-length bagging, Fixed-Length Seals for rigid transport totes, and Twist/Meter Seals for securing thin valves and specialized medical devices.

Let's break down the hardware:

- Pull-Tight Plastic Seals: These are the "cinch-up" seals. You see them on regulated medical waste bags or adjustable neck bags containing laundry or linens. They grip the bag neck tightly, preventing spills and contamination.

- Padlock Seals: These fit through the latch of a cabinet or a plastic tote box. They hang like a lock but are single-use. They are standard for "totes" moving drugs from the warehouse to the pharmacy.

- Meter Seals (Twist Seals): These are often overlooked but vital. They use a wire and a rotating locking mechanism. In hospitals, I've seen these used on medical gas cylinders, water meters, and calibration devices where the opening is too small for a plastic seal.

Securing the "Crash Cart": The Balance of Security and Speed?

In an emergency room, a locked drawer can be a problem if it takes too long to open. Yet, an unlocked drawer is a liability for drug theft. How do you solve this paradox?

For emergency "crash carts," hospitals use low-break-strength plastic seals. These seals keep the contents secure and audited, but are designed to snap open instantly with a firm tug, ensuring life-saving equipment is accessible in seconds.

This is a specific application called "Break-Away" protection. A crash cart is fully stocked with vital drugs and equipment. Once verified by the pharmacy, it is locked with a numbered plastic seal. This seal tells the nurses: "This cart is fully stocked and sterile." If the seal is broken, the cart is considered "used" and must be restocked. However, the mechanical design here is brilliant. Unlike a heavy-duty truck seal, these plastic seals are engineered with a specific weak point. I advise hospital clients to use seals with a break strength of under 3-4 kg. This ensures that in a cardiac arrest situation, a nurse doesn't need scissors; they just rip the drawer open, ensuring patient safety isn't compromised by the security measure protecting it.

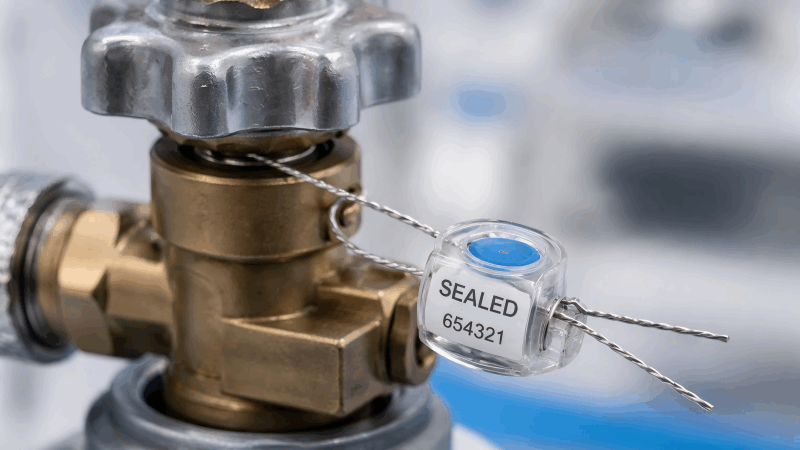

The Role of Meter Seals in Equipment Calibration and Safety?

Not all security is about theft; some of it is about precision. If a valve on a dialysis machine or gas tank is tampered with, the result could be fatal.

Meter seals, typically using wire and a plastic body, are used to secure small, irregularly shaped apertures on medical equipment. They ensure that calibration settings, gas valves, and diagnostic devices have not been altered since their last inspection.

This is a niche but critical area. Think about the metrology and calibration of sensitive medical devices. Once a technician certifies a machine, they need to ensure no one tweaks the settings. A standard plastic seal is too thick for these tiny holes. This is where the meter seal shines. A thin wire is threaded through the screw head or valve handle and twisted into the seal body. If that wire is cut, the technician knows the machine's calibration is void. I've worked with biomedical engineering departments that use color-coded meter seals to track inspection cycles (e.g., Red for 2023, Blue for 2024). It’s a simple mechanical solution to a complex compliance problem.

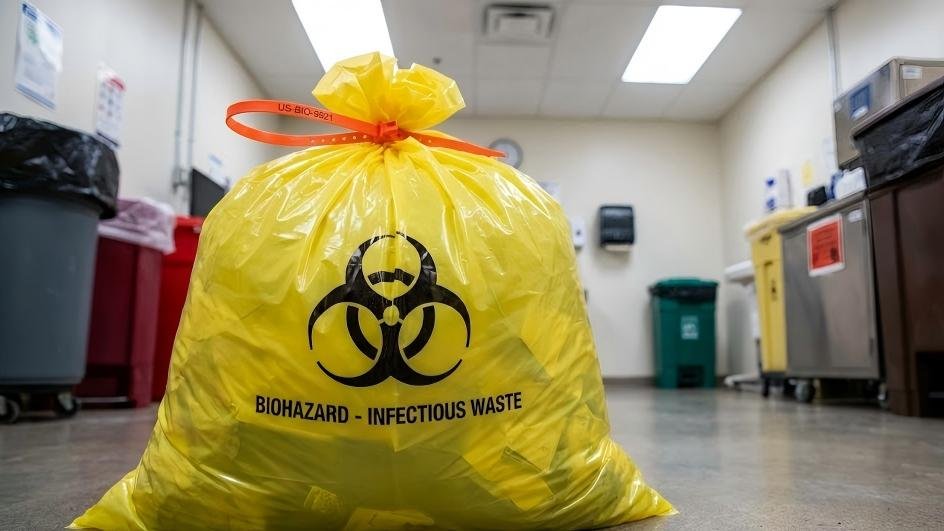

Preventing Cross-Contamination: Why Seals are Vital for Medical Waste?

Patient safety isn't just about successful treatment; it's about controlling what leaves the room. A loose knot on a biohazard bag is a health hazard waiting to leak.

Plastic pull-tight seals are the industry standard for securing clinical waste bags. They allow staff to perform the "swan-neck" sealing method, creating a liquid-tight closure that prevents the spread of pathogens and protects hospital porters from accidental exposure.

This application is crucial for environmental infection control. In many hospitals, "tying a knot" in a bag is no longer sufficient compliance. The risk of air or fluid escaping is too high. By twisting the bag neck and applying a spiked plastic seal, materials regulated under OSHA bloodborne pathogens standards are effectively quarantined. These seals often carry a unique number or barcode. This adds a layer of accountability that is often overlooked: if a waste bag is found dumped illegally or handled improperly, the barcode on the seal can trace it back to the specific ward or department responsible. This ensures that safety protocols are followed not just at the bedside, but all the way to the incinerator.

Supply Chain Integrity: From Warehouse to Hospital Ward?

Drugs don't magically appear in the hospital pharmacy; they travel through a complex supply chain. Every handover is a risk of diversion or contamination.

High-strength plastic seals and bolt seals secure the distribution aspect of healthcare. They lock the roll cages, plastic tote boxes, and truck doors that transport pharmaceuticals, providing a "chain of custody" that links the manufacturer to the patient.

This is where we combat diversion and ensure compliance with the Drug Supply Chain Security Act (DSCSA). Opioids and high-value medicines are targets. When a tote leaves the distribution center, it is sealed with a unique serial-numbered plastic seal. That number is logged on the manifest. When the tote arrives at the hospital dock, the receiving clerk checks the number. If the mechanical seal is intact and the number matches, the chain of custody is unbroken. If the seal is cut, or replaced with a different one, the shipment is rejected immediately. This mechanical barrier forces a thief to physically destroy the lock to get in, making covert theft nearly impossible and protecting the hospital from liability.

Conclusion

Mechanical security seals—from plastic pull-tight loops to delicate wire meter seals—are the hardware of healthcare safety. They provide the physical resistance and visual evidence necessary to prevent contamination and theft.

Secure Your Medical Operations with ProtegoSeal

Don't rely on stickers when you need a lock. At ProtegoSeal, we specialize in mechanical security solutions tailored for the medical industry, from low-break-strength crash cart seals to precision meter seals. Contact us today to find the right physical barrier for your patient safety protocols.