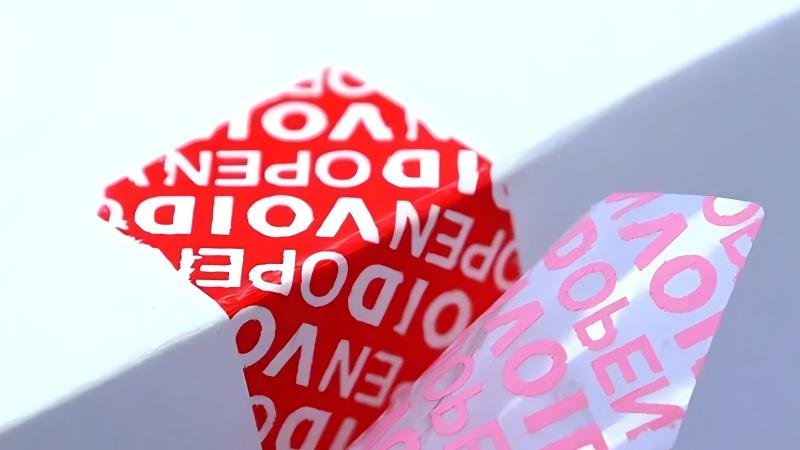

Do you treat your security labels like ordinary stickers? While they may look similar, relying on a standard label to secure your product is a critical risk. A standard label can often be peeled off with heat and patience, leaving no trace of entry.

A true VOID label represents a significant leap in technology. It is not just a label; it is a precisely calibrated, single-use evidence system.

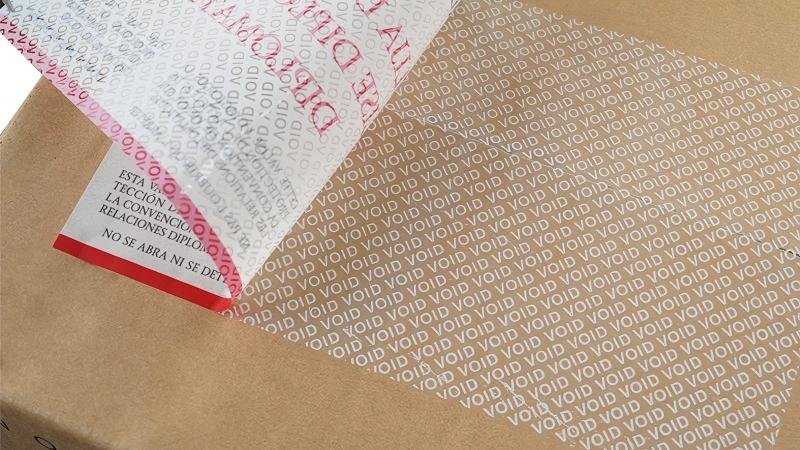

The core value isn't just adhesion; it is the capability to achieve a controlled, irreversible self-destruction upon a tamper attempt. As a manufacturer, our expertise lies in engineering this "destruction" process to ensure the evidence left behind is always clear, instant, and undeniable, transforming a simple adhesive product into a forensic tool.

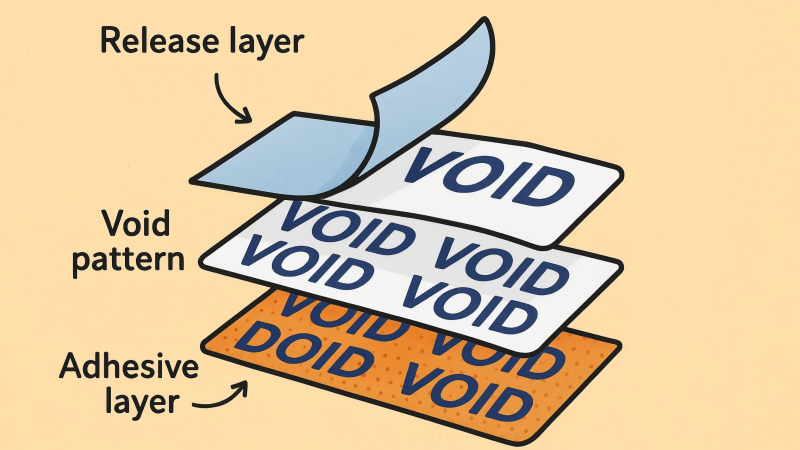

The Core Mechanism: How Layered Technology Reveals the Hidden Message

Ever wondered how that "VOID" message magically appears? It is the result of a clever, multi-layered design that is fundamentally different from a standard adhesive structure.

The secret lies in controlled delamination. A VOID label is engineered with multiple layers possessing different bond strengths. Think of it as a trap waiting to be sprung:

- Standard Labels: Typically consist of a face stock and a single adhesive layer. They peel off as one unit.

- VOID Evidence Systems: Constructed of a top film, a release coating, and a patterned adhesive layer.

We precisely calibrate the bond strengths between these layers. The bond between the top film and the release layer is intentionally made weaker than the bond between the adhesive pattern and your package. When a peeling force is applied, the system is designed to "fail" at that specific, engineered weak point. The top film lifts, but the patterned message remains securely bonded to the surface. It is a controlled failure that produces a predictable, permanent result.

The Key to Irreversibility: Why Residue Cannot Be Erased

What stops a thief from simply wiping off the "VOID" residue? This is the difference between a temporary mark and a permanent piece of forensic evidence.

The key is the chemical formulation of the adhesive. The adhesive is chemically engineered to create a powerful, permanent bond with the substrate (surface). It is designed to "love" the surface of your box more than it loves the label's top film.

"The goal is to create a mark that cannot be cleaned, erased, or denied. It's not just sticky; it's a form of chemical branding."

Once applied, the adhesive begins to cure. Trying to remove it with solvents often just smears the message or damages the packaging, creating even more evidence of tampering. This ensures the chain of custody remains unbroken—or clearly flagged if broken.

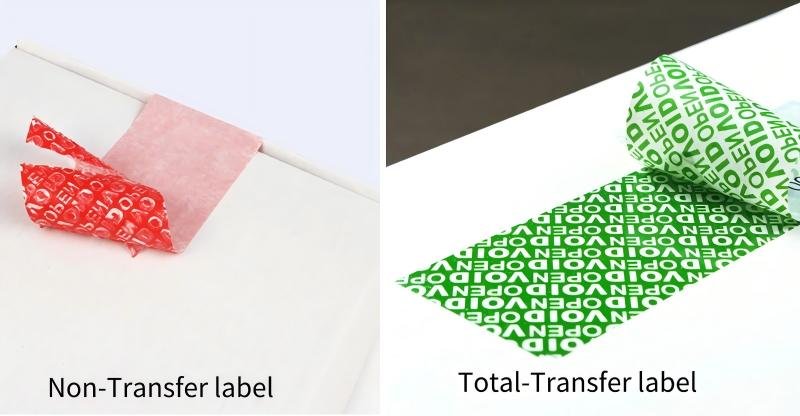

Forms of Evidence: Total-Transfer vs. Non-Transfer Labels

Did you know that not all VOID labels are designed to leave a sticky residue behind? Choosing the right "evidence style" is crucial for your specific application.

There are two primary distinct strategies for evidence presentation:

| Label Type | How It Works | Best Applications |

|---|---|---|

| Total-Transfer | Leaves a high-tack "VOID" adhesive residue on the surface AND shows the message on the label. | Disposable packaging: Cardboard boxes, shrink wrap, paper envelopes, pallets. |

| Non-Transfer | Leaves the surface perfectly clean. The "VOID" message appears only on the label itself. | Reusable assets: Car doors, luxury goods, IT equipment, glass, secure areas. |

A misapplication here is costly. Putting a total-transfer label on a reusable plastic medical tote would require expensive cleanup labor. Conversely, using a non-transfer label on a rough cardboard box might not provide the necessary "grip" to trigger the void message.

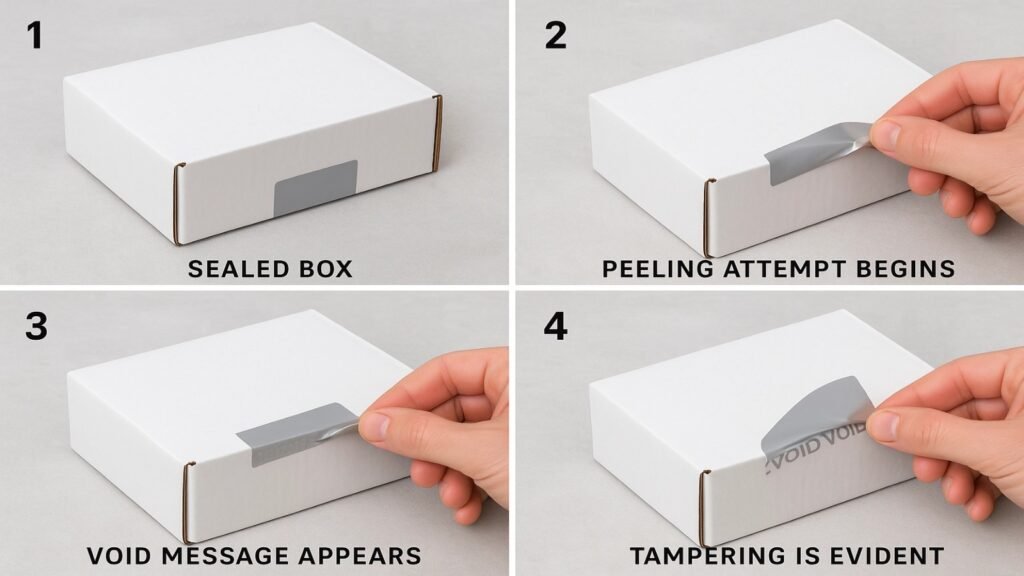

From Theory to Reality: The Tamper-Evidence Chain Reaction

How does this calibrated system perform in the real world? It is a rapid, irreversible chain reaction that begins the moment the label is lifted.

- Arming (Application): The label is applied. The adhesive immediately begins to cure, forming a bond with the substrate. The trap is set.

- The Breach (Attempt): A thief introduces a peeling force (fingernail or blade).

- System Trigger: The peeling force overcomes the engineered weak bond within the label layers.

- Permanent Record: The layers separate (delaminate). The hidden message is revealed instantly. There is no reset button.

Ensuring Integrity: The Critical Match Between Surface and Adhesive

Ever seen a security label that peeled off without triggering the VOID message? This is a classic case of system failure—not because the label was bad, but because it was mismatched with the surface energy.

For the evidence system to work, the adhesive must bond more aggressively to your box than it does to its own film. A mismatch is the #1 cause of failure.

The world is not made of one uniform material. Porous cardboard, smooth glass, and low-energy plastics (like Polypropylene) all react differently to adhesives. As a professional buyer, you must specify the application surface. As expert manufacturers, our job is to provide the perfectly calibrated adhesive system to ensure that label self-destructs as intended, every single time.

Conclusion

Stop thinking of VOID labels as mere stickers. They are sophisticated, single-use evidence systems designed for controlled, irreversible self-destruction. Their reliability depends entirely on the precise calibration between their layers, the adhesive chemistry, and your specific application surface.

Get Your Evidence System Calibrated by Experts

At ProtegoSeal, we specialize in calibrating tamper-evident technology. We will help you select the precise VOID label system that matches your specific substrate, ensuring your evidence chain remains unbreakable.

Contact us today for a consultation and test samples.