Choosing the wrong security seal can leave your valuable cargo exposed to theft, contamination, and unauthorized access. In the fast-paced world of logistics, this simple decision often means the difference between a secure delivery and a significant financial loss.

When selecting a high-security seal, the choice typically narrows down to two main contenders. For standard container doors requiring maximum brute-force resistance, a bolt seal is the superior choice. However, for irregular locking points or applications requiring operational flexibility, a cable seal provides a versatile and secure solution.

While the choice between a rigid bolt seal and a flexible cable seal seems straightforward, it represents two different security philosophies: Standardized Rigidity vs. Adaptive Flexibility. This guide breaks down the technical differences, ISO certifications, and specific use cases to help you protect your supply chain.

1. Understanding the Mechanical Differences: Rigidity vs. Flexibility

At first glance, both seals serve the same primary purpose: providing tamper evidence and acting as a barrier against theft. However, their mechanics and physical properties differ fundamentally.

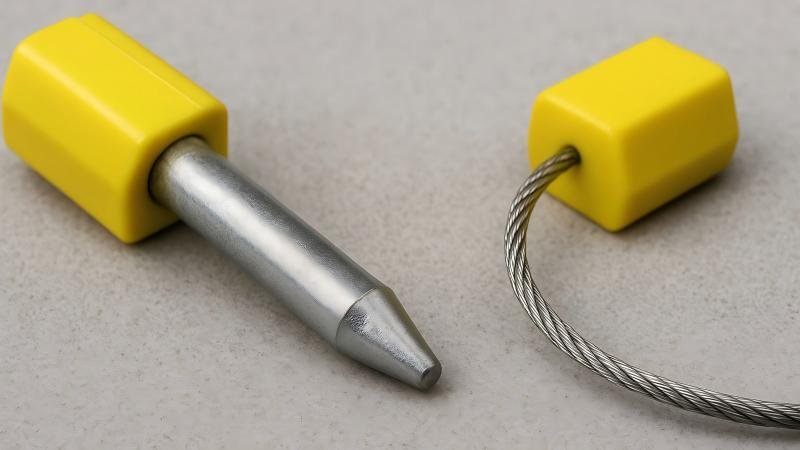

The primary distinction lies in their structure. A bolt seal consists of a rigid steel pin and a high-impact plastic-coated locking body (barrel). It is designed specifically to align two rigid holes. In contrast, a cable seal utilizes a variable-length galvanized steel wire that acts like a high-strength zip tie, allowing it to navigate complex or misaligned locking mechanisms.

Comparison at a Glance

| Feature | Bolt Seal | Cable Seal |

|---|---|---|

| Structure | Rigid Pin & Barrel | Flexible Steel Cable |

| Application | Standardized Holes (ISO Containers) | Irregular or Multiple Points |

| Tamper Evidence | Anti-spin features; must be cut | Cable frays/splays when cut |

| User Experience | "Click" to lock (Foolproof) | Pull-tight (Requires judgment) |

| Cost Efficiency | Generally lower cost | Higher cost for complex mechanism |

2. The Case for Bolt Seals: Maximum Security for Standard Containers

If you are shipping internationally using standard intermodal containers, the bolt seal is the undisputed industry standard. It offers "unambiguous security," meaning it is either locked or it isn't, reducing the chance of human error.

Designed to fit the hasps of standard shipping containers, ISO 17712 compliant bolt seals offer robust protection against physical attacks. They require heavy-duty bolt cutters to remove, acting as a strong visual and physical deterrent against opportunistic theft.

Best Applications for Bolt Seals:

- Cross-Border Logistics: Essential for meeting C-TPAT requirements.

- Ocean Freight: The rigid design withstands the harsh marine environment.

- High-Value Goods: Ideal for electronics and pharmaceuticals where maximum barrier strength is needed.

3. The Case for Cable Seals: Adaptive Solutions for Irregular Locking Points

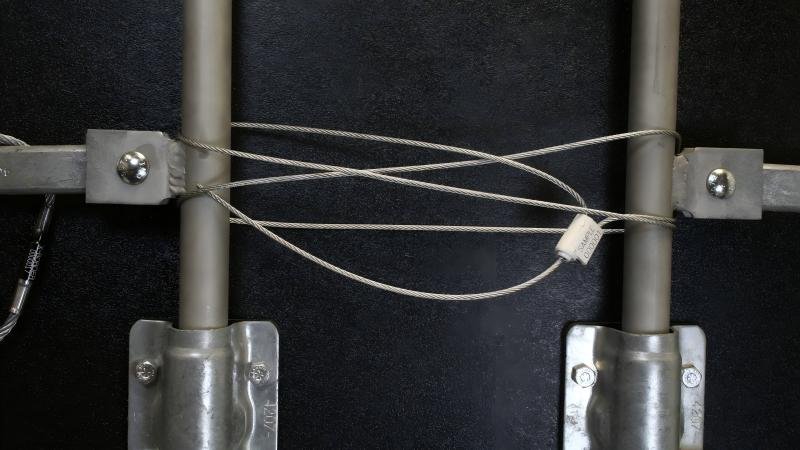

Rigid seals fail when locking points are misaligned, unusually shaped, or too far apart. This is where cable seals excel. A heavy-duty cable seal allows you to thread the locking mechanism through holes that don't line up perfectly.

Cable seals offer "adaptive security." You can adjust the cable length to pull the seal tight against the locking mechanism, preventing "gapping" that thieves could exploit. Additionally, the aircraft-grade steel cable creates a "splayed" end when cut, making it nearly impossible to rejoin without obvious signs of intrusion.

Best Applications for Cable Seals:

- Tanker Trucks: Securing valves and hatches to prevent liquid contamination.

- Rail Cars: Locking mechanisms on hoppers often vary in size and shape.

- Misaligned Doors: When a truck trailer door has shifted and a rigid bolt won't fit.

4. ISO 17712 Certification: Why “High Security” Status Matters

Whether you choose a bolt or cable design, compliance is key. Your seal must be ISO 17712 certified.

This international standard classifies seals into three categories ("I" for Indicative, "S" for Security, and "H" for High Security). For international shipping entering the USA, you must use an "H" Class High Security Seal.

Testing requirements include:

- Tensile Test: Pulling the seal apart to measure strength.

- Shear Test: Cutting the seal to test resistance.

- Impact Test: Striking the seal to ensure durability.

Warning: Using a non-compliant seal can lead to your cargo being held at customs. Always ensure your supplier provides documentation proving their seals meet the "H" classification.

5. Strategic Selection Guide: 4 Questions to Determine Your Best Fit

Choosing a seal based only on price compromises security, while overspending affects your bottom line. Ask these four questions before purchasing:

- What is the physical locking point? (Bolt for hasps, Cable for valves).

- What is the value of the cargo? (High value requires "H" Class).

- Does the shipment cross borders? (Requires ISO 17712 compliance).

- What is your operational workflow? (Bolt is faster; Cable is more versatile).

Conclusion

Ultimately, choosing between a bolt seal and a cable seal is about matching the right tool to the right job. You are deciding between the rigid, standardized security of a bolt seal and the adaptive, versatile security of a cable seal.

Don't leave your cargo security to chance. At ProtegoSeal, we specialize in ISO 17712 compliant high-security seals tailored to global logistics standards. We work with you to analyze your cargo value and shipping routes to recommend the most robust solution.

Ready to secure your supply chain?

Contact our security specialists today for a free consultation or to request a sample kit.