Your rail shipments are part of a massive, expanding network. But as volume grows, so does vulnerability. How do you secure assets across thousands of miles of open track?

The global railroad industry is undergoing a historic expansion. According to a recent industry report, the market is projected to hit $781.2 billion by 2030. While this signals a golden era for freight efficiency, it presents a stark challenge for logistics directors: volume creates visibility gaps.

As rail networks expand to handle this 4.5% CAGR growth, cargo becomes a static target in congested yards and remote sidings. This surge directly drives the demand for high-strength cable seals. These aren't just accessories; they are critical "Barrier Class" security devices that ensure C-TPAT compliance and maintain the chain of custody.

The Link Between Rail Growth and Cargo Theft Risks

Why does a booming market lead to higher risks? The answer lies in the logistics of scale. The expansion of rail networks means goods are traveling further, dwelling longer in transshipment hubs, and passing through more hands.

For security professionals, the Research and Markets report confirms a worrying trend: Increased freight density leads to increased opportunistic theft.

The "Sitting Duck" Problem

Rail freight is cost-effective and sustainable, but it often involves stops in unmonitored areas.

- Congestion: Higher volumes mean trains sit longer in queues at ports and depots.

- Static Assets: A stationary container is the easiest target for pilferage.

- The Solution: Relying on indicative plastic seals is akin to leaving the door unlocked. The industry is shifting toward 3.5mm+ adjustable cable seals that require heavy-duty bolt cutters to remove, turning a quick "snatch and grab" into a difficult, noisy operation.

Why Cable Seals are the "Barrier" Standard for Rail

In the hierarchy of security seals, rail freight demands the top tier. High-strength cable seals are classified as Barrier Seals under ISO 17712 standards. Unlike plastic seals that only show visual evidence of tampering, barrier seals physically prevent the doors from opening.

Key Security Features for Rail Logistics

| Feature | Security Function | Benefit to Supply Chain |

|---|---|---|

| Braided Steel Cable | Resists cutting with standard pliers or saws. | Deterrence: Thieves skip hardened targets to find easier marks. |

| ISO 17712 "H" Certified | Meets high-security testing for impact, shear, and tensile strength. | Compliance: Mandatory for C-TPAT and cross-border shipments. |

| Non-Preformed Cable | The wire unravels (splays) if cut. | Anti-Tamper: Impossible to re-seal or glue back together without detection. |

| Laser Etching | Permanent marking of serial numbers. | Traceability: Prevents the use of cloned or fake seals. |

Cross-Border Trade: Where Liability Meets Security

With the US market valued at $115.8 Billion and China projected to reach $132.2 Billion, international rail trade is the backbone of the global economy. However, crossing borders introduces complex liability issues.

The Chain of Custody Protocol

When a shipment moves from Mexico to the US, or across the EU, who is responsible if goods go missing? A high-security cable seal acts as the definitive judge.

- Origin: Uniquely numbered seal applied and recorded on the Bill of Lading.

- Handover: Intermodal transfers (Rail-to-Truck) verify the seal is intact.

- Liability: If the seal is broken upon arrival, liability shifts to the carrier. If the seal is intact but goods are missing, the issue occurred at the origin.

Without a high-strength, compliant seal, these disputes become costly "he-said, she-said" legal battles.

Protecting the Infrastructure: Securing Locomotives and Signals

The railroad boom isn't just about what is inside the containers. The train assets themselves are becoming high-tech and high-value. The industry push toward electrification and high-speed rail means locomotives now house millions of dollars in sensitive copper wiring and electronics.

Cable Seal Applications Beyond Cargo:

- Locomotive Engine Panels: Prevent theft of copper components.

- Signal Boxes: Secure critical infrastructure from vandalism (see Railway Signal Boxes).

- Maintenance Hatches: Ensure only authorized mechanics access high-voltage areas.

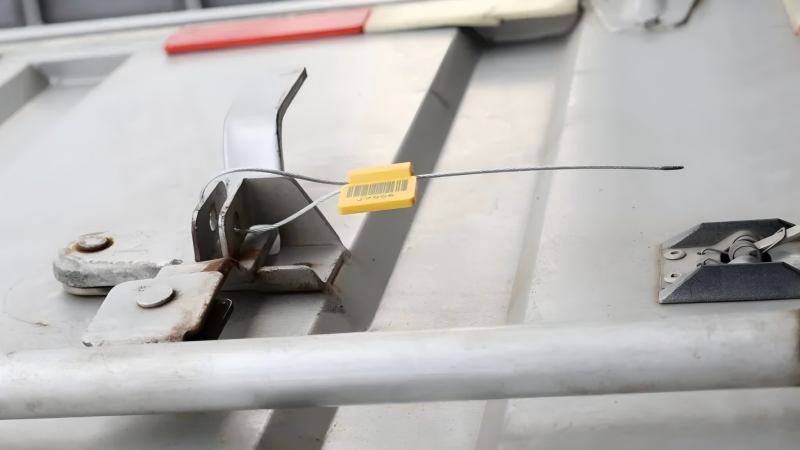

We recommend adjustable length cable seals for these applications, as they can be cinched tight around odd-shaped latches and machinery, ensuring a zero-gap fit.

The Future: Integrating Seals with IoT and Digital Tracking

The industry report highlights the "integration of digital technologies, including IoT." This is the next frontier of rail security. A seal is no longer just a piece of metal; it is the physical anchor for your digital data.

The "Physical-Digital" Handshake:

- QR Codes: Modern cable seals come with laser-engraved QR codes.

- Instant Verification: Yard staff can scan the seal to verify it against the digital manifest immediately.

- Evidence: If a seal is broken, a photo is uploaded to the cloud instantly, time-stamped with GPS coordinates.

This combines the brute strength of a steel cable with the intelligence of modern logistics software.

Buying Guide: What to Look for in Rail Cable Seals

Not all cable seals are created equal. For rail applications, using a seal that fails under the vibration and shock of a moving train is a liability.

The "Rail-Ready" Checklist:

- Diameter: Minimum 3.5mm to 5.0mm cable diameter is recommended for railcars.

- Material: Anodized aluminum body (corrosion resistant) with galvanized steel wire.

- Mechanism: One-way locking mechanism using steel rollers (not plastic).

- Compliance: Must carry the ISO 17712:2013 "H" mark.

Frequently Asked Questions (FAQ)

Why are cable seals preferred over bolt seals for rail?

While bolt seals are strong, cable seals offer flexibility. Railcar latches are often bent or misaligned due to heavy use; a flexible cable can fit through these difficult hasps where a rigid bolt cannot.

What is the minimum cable diameter for rail shipments?

For intermodal containers on rail, a 3.5mm diameter is the standard industry recommendation to qualify as a "High Security" barrier seal.

Are cable seals C-TPAT compliant?

Yes, provided they are ISO 17712 "H" (High Security) certified. Using non-certified seals can result in customs delays and fines.

Conclusion: Security Must Match Growth

The railroad industry is growing at an unprecedented rate, projected to reach nearly $800 billion. As your logistical reach expands, your security protocols must evolve. High-strength cable seals are the cost-effective, compliant, and robust solution to protect this new wave of global commerce.

Ready to upgrade your rail security?

At ProtegoSeal, we specialize in ISO 17712 compliant barrier seals designed for the rigors of rail transport. Contact our team today to secure your supply chain.