Worried your bag seals aren't truly secure? An improperly applied seal offers a false sense of security, making it a liability. True protection comes from a strict, standardized application protocol.

To apply a bag seal for maximum security, always inspect it first, thread it correctly through the bag, pull it tight to lock, and immediately record the unique serial number in a log. This simple protocol transforms the seal from a piece of plastic into a verifiable security event.

I'll share a story. A client was losing cash from their deposit bags. The seals looked fine. The problem wasn't the seals themselves; it was the process. Staff would grab any seal, apply it loosely, and not log the number until later. This created loopholes. My core belief, born from years of experience, is that a security seal's power is only one-third its design. The other two-thirds come from the rigorous, standardized protocol you build around it. The seal is just the physical proof of a process done right. Let's walk through that protocol.

Step 1: The Pre-Use Inspection for Every Bag Seal

You just received a new shipment of seals, but the process has already begun. Skipping a quick pre-use check is like leaving your front door unlocked. It's an open invitation for trouble.

Before you even think about applying it, you must inspect every single bag seal. Check that the serial number is clear and matches your inventory log, and ensure there are no signs of pre-tampering or manufacturing defects. This is your first line of defense.

This step is non-negotiable. I once troubleshooted an issue for a logistics company where sealed bags were arriving with different seal numbers than recorded. The problem was traced back to the source: a few bags of new seals had duplicate serial numbers from a faulty production run by their previous supplier. This tiny error invalidated their entire audit trail and cost them thousands in a disputed loss claim. Your inspection isn't just about checking for cracks; it's about verifying the seal's unique identity. This foundational step confirms that the "physical credential" you are about to use is legitimate and ready to be entered into your security system.

Your Pre-Use Checklist

- Unique Identity: Is the serial number clearly printed, not smudged, and unique?

- Structural Integrity: Are there any stress marks, cracks, or discoloration, especially around the locking mechanism?

- Locking Jaws: Look into the locking chamber. Do the metal or plastic jaws look intact and properly seated?

- Consistency: Does the seal look and feel identical to the others in the same batch? Any variation is a red flag.

This 15-second check is the first, crucial link in your Chain of Custody and establishes the integrity of the entire process that follows.

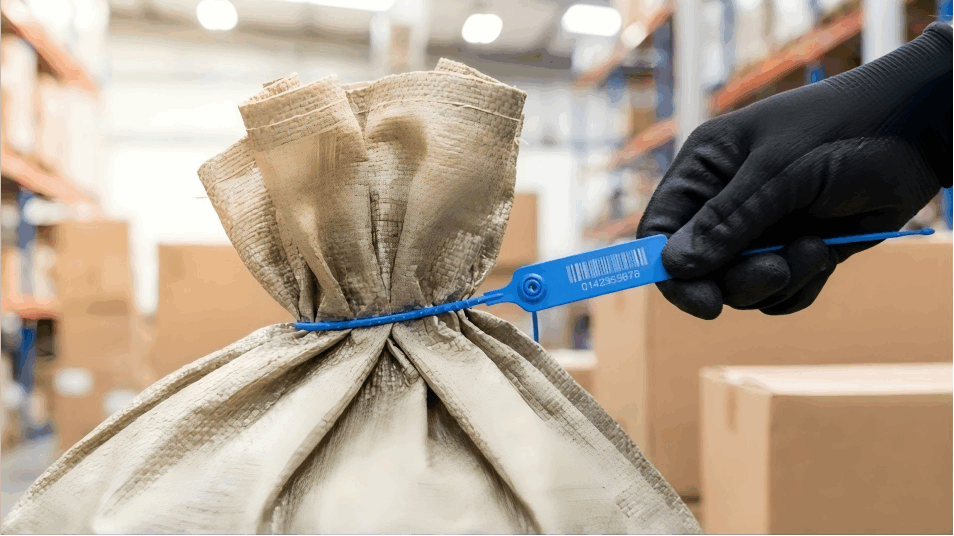

Step 2: How to Correctly Apply and Lock Your Bag Seal

The most common failure point I see is not the seal, but the application. A loose or incorrectly threaded seal is a sign of a weak protocol and a target for tampering.

To apply a bag seal correctly, thread the tail through the bag's eyelets, insert it into the locking chamber, and pull it as tight as possible. You must hear a distinct "click" as the locking mechanism engages. The seal should have no slack.

This "pull-tight" action is the most critical part of the physical application. A common method of bypass is to manipulate a loosely applied seal. For instance, with some seals, if there is enough slack, it's possible to use a thin shim to release the lock or to heat and stretch the plastic. By pulling the seal absolutely taut, you eliminate the space needed for such manipulation. I always teach clients to perform the "pull-back test." After you hear the click and think it's locked, give the tail a sharp tug backward. If it moves even a millimeter, it wasn't fully seated. Pull it tighter. The goal is to make the seal an integrated part of the bag, not just a loose accessory hanging off it.

Common Application Mistakes to Avoid

| Mistake | Consequence | The Right Way |

|---|---|---|

| Loose Application | Leaves room for manipulation, shimming, or heat attacks. | Pull the seal as tight as physically possible. No slack. |

| Incorrect Threading | Doesn't secure the bag correctly; can be bypassed easily. | Ensure the seal passes through all designated eyelets or closure points. |

| Not Hearing the "Click" | The locking mechanism may not be fully engaged. | Listen for the distinct click and always perform a pull-back test. |

This step is where your security protocol becomes a physical reality. Precision here is everything.

Step 3: Documenting and Verifying Your Locked Bag Seal

A locked seal without a record is just a piece of plastic. The documentation step is what turns the physical act into a legally and operationally defensible security event.

Immediately after locking the seal, the operator must record the serial number, date, time, and their own identifier in a dedicated logbook or digital system. The data must be captured at the moment of application.

This is where so many protocols fail. I've seen warehouses where operators write down serial numbers on scrap paper, intending to enter them later. This delay is a massive security hole. It invites transcription errors and, more dangerously, allows a dishonest employee to record one number while applying a different, unlogged seal to cover a theft. The rule must be absolute: the log is filled out at the bag, at the time of sealing. In high-stakes environments, a "two-person rule" or having a supervisor verify the number against the log entry adds another layer of internal control. This documentation is your primary evidence in any dispute. Without it, you cannot prove the bag was sealed securely.

The Four Pillars of Effective Documentation

- Immediacy: Record the data at the exact moment of sealing. No delays.

- Completeness: The record must include the Seal #, Date, Time, Location/Asset ID, and Operator Name/ID.

- Accuracy: The number recorded must be double-checked against the physical seal number.

- Integrity: Use a bound logbook with numbered pages or a secure, audited digital system to prevent fraudulent entries.

Your logbook is the memory of your security system. If it's weak, your security has amnesia.

Why Do Some Plastic Seals Fail When Securing Bags?

A client once called me, frustrated. "Your seals are breaking!" After investigation, the issue wasn't the seal's quality but a mismatch between the seal and its job. They were using a light-duty seal on heavy, overstuffed cash bags.

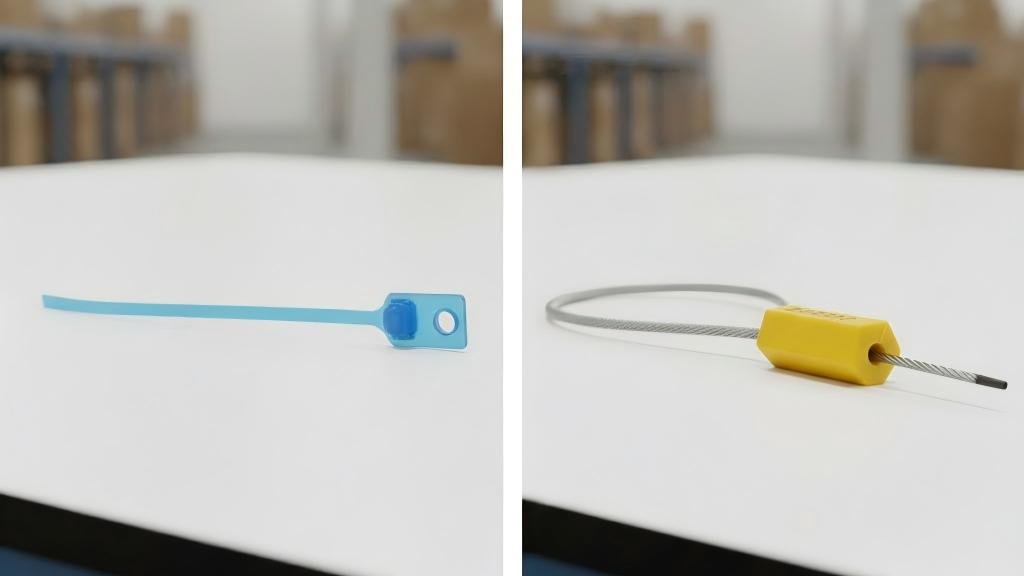

Plastic seals fail for two main reasons: they are the wrong type for the application (e.g., trying to use a low-tensile strength seal on a heavy-duty bag), or they have been degraded by environmental factors like UV light or chemicals.

Choosing the right tool for the job is a core principle of risk management. It's crucial to consider the bag's material and typical contents. Will the bag be thrown, stacked, or exposed to the elements? For heavy canvas bags or bulk bags that put a lot of strain on the closure, a seal with low tensile strength is guaranteed to fail. You need a seal with a thicker strap and a robust locking mechanism, possibly with a metal insert. Furthermore, standard polypropylene seals can become brittle with prolonged sun exposure. If your bags will be stored outdoors, you need seals made with UV-resistant additives. The failure isn't in the plastic; it's in the planning.

Matching the Seal to the Mission

- For Cash/Deposit Bags: Use a medium-duty seal with a clear "click" and features that show evidence of heat tampering.

- For Mail/Courier Sacks: A simple, pull-tight, consecutively numbered seal is often sufficient.

- For Bulk Ingredient/Aggregate Bags: A heavy-duty, high-tensile strength seal is required to handle the weight and stress.

How Can You Spot Tampering on a Bag Seal After Use?

A seal has done its job even if it arrives broken—as long as you can tell why it's broken. The final step of the protocol is the receiving inspection, where you hunt for signs of tampering.

Beyond being broken or missing, you must inspect a used seal for subtle signs of manipulation. Look for stress marks, discoloration from heat, scratches around the locking chamber, or signs of superglue.

This is forensic work. Amateurs will try brute force, leaving obvious evidence. Professionals are more subtle. They might use a very thin piece of metal (a shim) to try and release the locking jaws, which leaves microscopic scratches. They might use a heat gun to try and weld the tail back together, which often causes a slight discoloration or a glossy texture. My QC background taught me to look for what's out of place. After cutting a seal off for legitimate access, I recommend keeping the used seals for a short period. If a discrepancy is found later, these used seals become key evidence. This practice of inspecting and retaining seals turns your receiving dock into the final checkpoint of your security protocol.

Tampering Red Flags

- Stress Marks: White or discolored lines on the plastic, indicating bending or stretching.

- Scratches/Tool Marks: Any marks near the lock, especially inside the opening.

- Chemical/Adhesive Residue: A sticky feel or glossy spots could indicate a superglue attack.

- Color Mismatch: The tail and the body of the seal should be the exact same color and texture.

- Number Discrepancy: The most obvious sign: the number on the seal doesn't match the number in your log.

Conclusion

A bag seal is not a magic charm. Its power is unlocked only through a strict, consistent protocol of inspection, application, and documentation. This process is your real security.

Turn Your Process into Protection with ProtegoSeal

A strong protocol needs a reliable physical token. At ProtegoSeal, our bag seals are designed to work within your security system, providing clear evidence of correct procedure and any attempts at tampering. Contact us to find the right seal to fortify your security protocol.