Choosing the right security seal can be confusing. You see a heavy, expensive bullet seal next to a simple plastic one and wonder, is the price difference really worth it? Making the wrong choice can lead to a rejected shipment, hefty fines, or a security breach you can't prove.

The key difference isn't just strength; it's purpose. Bullet seals are high-security seals built to meet strict international standards like ISO 17712. "Regular" seals are versatile seals designed for a wide range of specific applications where tamper evidence is needed without the high-security requirement.

When I first started in this industry, I struggled to explain this to clients. The 'aha!' moment came when I realized the core truth you provided: bullet seals are "born for standards," and regular seals are "born for application." The bullet seal's incredible strength isn't just to "lock" the cargo; it's to "lock in" responsibility and prove compliance across international borders. The regular seal's value is in its information—its unique number—not its physical power.

What Are Bullet Seals and "Regular" Seals?

The industry uses many terms, which can be confusing. You hear "bolt seal," "bullet seal," "plastic seal," "pull-tight seal." It’s easy to get lost and order the wrong product.

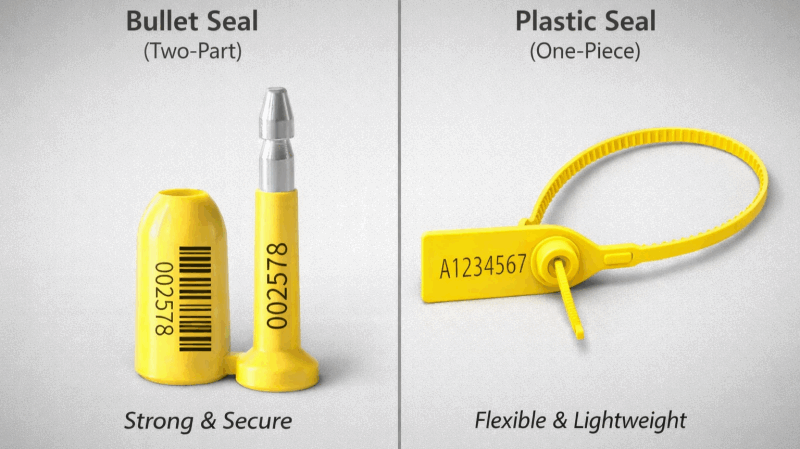

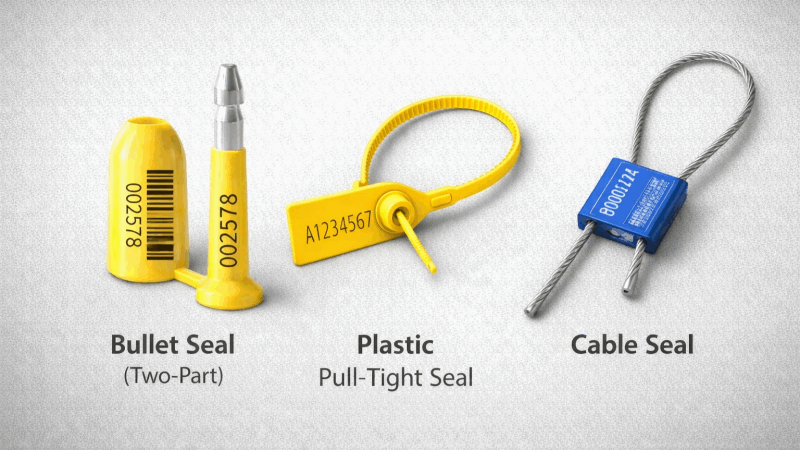

Let's clarify. A "bullet seal" is a specific type of high-security bolt seal, consisting of a steel pin and a separate locking body. "Regular seals" is a broad term covering diverse models like plastic pull-tight seals, fixed-length seals, or cable seals.

Thinking of them in these two buckets—one for high-security compliance and one for versatile application—simplifies everything.

Defining the Categories

To make it even clearer, let's break down their defining characteristics. This will help you immediately identify which category a seal falls into.

| Characteristic | Bullet Seal (Bolt Seal) | "Regular" Seal (e.g., Plastic Seal) |

|---|---|---|

| Common Name | High-Security Bolt Seal, Bullet Seal, Bottle Seal | Plastic Seal, Pull-Tight Seal, Truck Seal, Cable Seal |

| Structure | Two separate parts: a steel pin and a locking body. | Typically a one-piece, integrated design. |

| Primary Material | Heavy-duty steel core, often covered in plastic. | Polypropylene or Nylon plastic, sometimes with a small metal insert. |

| Primary Use Case | Cross-border shipping containers requiring ISO 17712 compliance. | Domestic trailers, bags, utility meters, fire extinguishers, first-aid kits. |

Which Is More Secure: A Bullet Seal or a Regular Seal?

Looking at a tough steel bullet seal next to a plastic strap, the answer seems obvious. But "security" means more than just raw strength.

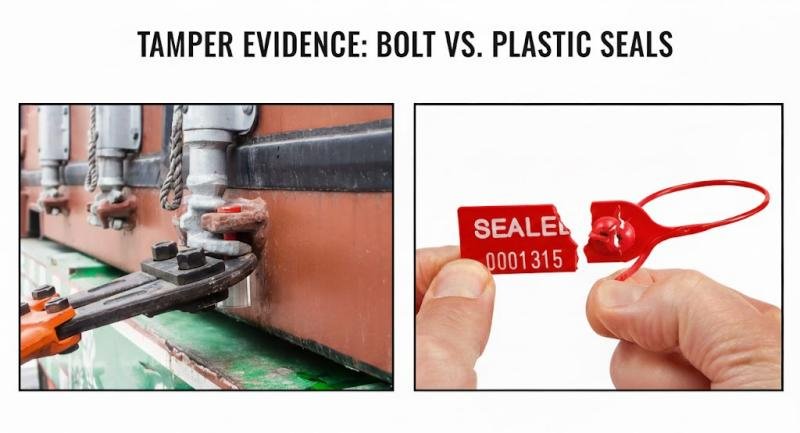

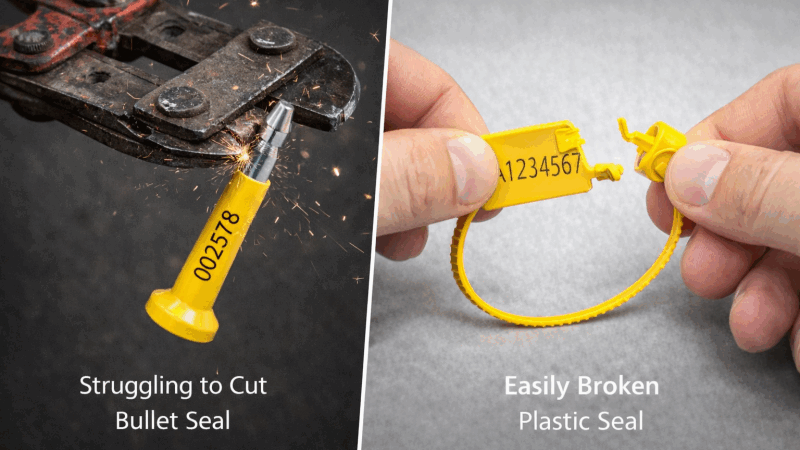

A bullet seal is physically more secure, requiring bolt cutters and significant force to remove. A regular seal is less physically robust but provides excellent tamper evidence. The question is, which type of security do you actually need?

The real answer depends on the threat you are trying to prevent. The bullet seal is designed to resist brute-force attacks and meet regulatory requirements. You can't remove it without leaving a trail of destruction. A regular seal is designed to provide a clear, instant visual indicator that someone has tried to gain access, even if they used minimal force. Its value lies in its "information attribute"—it tells you that a breach occurred. This is a core tenet of layered physical security: matching the tool to the specific risk.

When Should You Use a Bullet Seal Instead of a Regular One?

Using a bullet seal on a first-aid kit is overkill and a waste of money. Using a plastic seal on an international container will get your shipment stopped at the port.

You must use a bullet seal when shipping containers internationally to comply with customs regulations like the C-TPAT program. Use a regular seal for domestic logistics, inventory control, or securing low-risk items where a clear tamper indicator is sufficient.

I once had a client who was frustrated with the cost of bullet seals. They shipped baked goods domestically and saw no need for such high security. They were right. We switched them to a simple, sequentially numbered plastic seal. This saved them money while still giving them what they needed: a unique ID to track each shipment and a clear way to see if a truck had been opened before arriving at the grocery store. The "application" called for an information tool, not a fortress. Conversely, any client shipping overseas gets one answer: you need a compliant, high-security bullet seal. No exceptions.

Is the Higher Cost of Bullet Seals Justified for Your Business?

The price tag on a bullet seal can be 5 to 10 times higher than a simple plastic seal. This leads to a natural and important question: are you paying for security you don't need?

The higher cost is justified if non-compliance with international shipping standards could lead to delays, fines, or rejected cargo, costing you far more than the seals. For lower-risk, domestic applications, the cost is likely not justified.

This is a business decision, not just a security one. You have to weigh the upfront cost of the seal against the potential financial impact of a security failure. For an international shipper, a $2,000 daily demurrage fee from a container held up at port makes the $2 cost of a compliant bullet seal seem trivial. For a local bakery, that math doesn't add up. The cheaper plastic seal perfectly matches their risk profile and business needs. The key is to see the seal not as a standalone expense but as a form of risk management insurance.

How Do Material and Design Differences Impact Tamper Evidence?

You might think that because a bullet seal is stronger, it provides better tamper evidence. This isn't always true. The material and design are tailored to reveal different types of attacks.

A bullet seal’s steel core is designed to show evidence of cutting or brute force. A plastic seal’s one-piece design is made to show evidence of pulling, stretching, or sophisticated heat/freezing attacks, as the material will whiten or break in a very specific way.

This goes back to the core insight. The bullet seal is designed to withstand and show evidence of the kind of attack expected on a high-value container—a deliberate, forceful breach. Its tamper evidence is about structural failure. Regular seals, especially high-quality plastic ones, are marvels of material science. They are designed to be weak in a very specific, predictable way. I've seen plastic seals that will permanently change color if exposed to a heat gun, or snap instantly if a solvent is applied. Their "weakness" is their greatest strength because it makes them a highly sensitive information tool.

Conclusion

The choice between a bullet seal and a regular seal is a choice of purpose. Bullet seals are for compliance and high-risk security. Regular seals are for versatile applications where tamper evidence and information are key. Knowing the difference protects your cargo and your bottom line.

Choose the Right Seal for the Right Job with ProtegoSeal

Don't get caught using the wrong tool. Whether you need ISO 17712 certified bullet seals for international compliance or cost-effective plastic seals for domestic logistics, we have the solution. Let us help you match the seal to your specific application. Contact ProtegoSeal for an expert consultation.