You see a shimmering hologram on a product and assume it's genuine. But what if it's just a cheap, shiny sticker that offers zero protection, leaving your customers vulnerable and your brand reputation at risk?

The difference between a high-security hologram and a fake lies in its integrated, layered security features. A genuine label combines true 3D depth, tamper-evident destruction, microscopic text, and specialized adhesives. A fake merely imitates the shiny surface effect with none of the underlying technology.

Early in my career, I was fooled by a convincing-looking fake. It shimmered, it was bright, but when we put it under a microscope, it was just a pretty picture. That's when I learned the most critical lesson: a genuine hologram is a system. All its security features are designed and manufactured together in a single, complex process. A fake is just a cheap assembly of unrelated parts. This teardown guide will teach you how to spot that fundamental difference.

The Hologram's Optical Effect: True 3D Depth vs. A Simple Reflective Sheen

The sticker shines and changes colors as you tilt it. This is the most basic feature of a hologram, but it's also the easiest to fake, creating a false sense of security.

A genuine high-security hologram exhibits true 3D depth and parallax. This means that as you tilt it, you can see different layers of the image moving over one another. A fake is typically a flat, iridescent film that just reflects a rainbow of colors, like an oil slick on water, with no sense of depth.

This visual depth isn't just a neat trick; it's the direct result of a highly advanced manufacturing process. This is the first clue of a "systematic" design.

How the Optical Effect is Made

- Genuine Holograms: Created using sophisticated techniques like dot-matrix or even electron-beam lithography. These methods record information on multiple optical layers within the label, creating a true three-dimensional illusion. This process is expensive and requires specialized labs.

- Fake Holograms: Often use cheap, mass-produced diffraction foil. This material is designed to split light into a spectrum of colors but has no actual layered image information encoded into it. It's a surface effect only.

When I inspect a label, I tilt it back and forth. Am I just seeing a rainbow, or can I see a background element passing behind a foreground element? That movement, or parallax, is a sign of an expensive, integrated creation process that counterfeiters can't easily replicate.

The Tamper-Evident Feature: Destructible Holographic Layers vs. Labels That Peel Off Cleanly

You suspect a product is fake, but the hologram looks untouched. If a counterfeiter can peel it off one item and reapply it to another, the sticker is worse than useless—it's actively misleading.

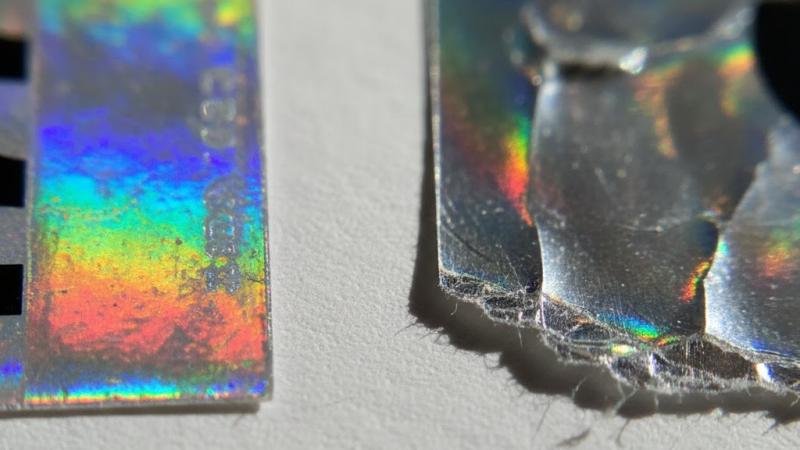

A high-security hologram is designed to self-destruct upon removal. The holographic layer is intentionally made to be more fragile than the adhesive bond, causing it to flake apart or split, leaving behind clear and irreversible evidence of tampering. A fake label often peels off in one piece.

This is where the "system" becomes physical. The optical layer and the adhesive layer are engineered to work against each other. During one project, we tested a new batch of security labels. When our lab tried to peel one off, the top holographic layer disintegrated into a fine, glittery dust, leaving the adhesive and parts of the image behind. It was impossible to put back together. That's the sign of a true security feature, not just a sticker. It's a key part of maintaining the product's chain of custody.

| Feature | High-Security Hologram | Fake/Low-Security Sticker |

|---|---|---|

| Tamper Response | Fractures, delaminates, or self-destructs. | Peels off cleanly or in large chunks. |

| Underlying Principle | Adhesive bond is stronger than the label's material. | Label material is stronger than the adhesive. |

| Result | Irreversible evidence of tampering. | Can be reapplied to another product. |

Microscopic Details: Hidden Text Within the Hologram vs. A Blank or Blurry Surface

You're looking at a hologram with the naked eye and it seems fine. But the real secrets of a high-security label are often too small to see, a detail most counterfeiters completely ignore.

A high-security hologram often contains microtext or nanotext—letters or symbols so small they are invisible to the naked eye and can only be read with a magnifying glass or microscope. On a fake hologram, these areas will either be completely blank, or you'll see a blurry, unreadable smudge.

The presence of crisp, legible microtext is one of the strongest indicators of authenticity. The laser etching technology required to produce this effect is precise and expensive. It's integrated directly into the master hologram's creation. Counterfeiters using simple printing or foil-stamping methods cannot replicate this level of detail. I always carry a 30x jeweler's loupe with me to trade shows. It's a simple tool that allows me to perform this teardown in seconds. When I focus on an area that should have microtext and see sharp, perfect letters, I know I'm looking at a product from a manufacturer who invested in a proper security system.

Adhesive Technology: "VOID" Patterns Left by Hologram Labels vs. No Trace at All

A product has been tampered with, but after the fake sticker is removed, there's no evidence left. The criminal leaves no trace, making it impossible to prove an item was compromised.

Many high-security labels use specialized tamper-evident adhesives. When someone attempts to remove the label, it leaves behind a specific word pattern, often "VOID," "OPENED," or a custom design. This provides a clear, undeniable message of tampering. A fake sticker simply has a generic adhesive.

This is another perfect example of "systematic integration." The adhesive layer is not just sticky stuff; it's a technology in itself. It is a two-stage system: part of the adhesive is engineered to stick to the product, while a release layer between it and the label breaks in a pre-determined pattern. Creating this requires advanced adhesive coating techniques. When I see a "VOID" pattern left behind, I know that the designer didn't just pick a hologram and an adhesive; they chose an integrated tamper-evident system where both parts were designed to work together to achieve a specific security goal.

Manufacturing Craft: Precise Die-Cut Edges vs. Rough Edges on the Hologram Pattern

You are examining a sheet of hologram labels. They look okay from a distance, but something feels "off." The sloppiness is often in the small details that reveal a cheap manufacturing process.

A genuinely manufactured hologram label has clean, precise, and uniform die-cut edges. The holographic image itself is also perfectly aligned within the edges of the label. Fakes often have rough, fuzzy edges, or the holographic pattern is slightly misaligned or bleeds over the cut edge.

This might seem like a minor cosmetic point, but it speaks volumes about the manufacturer's Quality Control. High-volume, professional security label production uses precision machinery for slitting and die-cutting. This ensures every single label is identical. Counterfeit operations, on the other hand, often use cruder methods that result in inconsistency. When I was a QC inspector, I learned to run my thumbnail along the edge of a label. A smooth edge indicates a professional die-cut. A rough or uneven edge is a red flag that points to a low-tech, unreliable production process—the opposite of a security system.

Conclusion

A high-security hologram label is a system of integrated technologies, while a fake is just a surface imitation. By tearing down its layers—from optics to adhesive—you verify the authenticity of the entire system.

Build Your System of Trust with ProtegoSeal

Don't settle for a simple shiny sticker. To secure your brand, you need a true security system. ProtegoSeal specializes in creating systematically integrated hologram labels with layered security features. Contact us to design a solution that counterfeiters can't tear down.