You're staring at a catalog of container seals—bolts, cables, barriers—and they all start to look the same. Choosing the wrong one can lead to customs fines, cargo theft, or insurance claim denials.

The different types of container seals are best understood not by their shape, but by their primary security job. These jobs fall into three main levels: providing tamper evidence (Indicative Seals), meeting regulatory compliance (High Security Seals like Bolt & Cable Seals), or offering active physical defense (Barrier Seals).

For years, I made the mistake of thinking about seals based on what they were—a piece of plastic, a metal bolt. The real breakthrough in my understanding came when I started asking why they exist. Each type of seal is a specialized tool, designed to solve a specific problem for a specific role in the global supply chain. The question isn't "what is this seal," but rather, "what security job does this seal perform?" Understanding this changes everything.

Container Bolt Seals: Why Are They the Default for Global Freight?

You need to ship a container overseas. You know it needs a seal, but picking one that gets rejected by customs at the destination port could cause disastrous delays and fees.

Container bolt seals are the default for global freight because their core job is to ensure regulatory compliance. They are engineered to meet the strict ISO 17712 standard for "High Security Seals" (HSS), which is a mandatory requirement for programs like the Customs Trade Partnership Against Terrorism (C-TPAT).

When I first started, I thought the strength of a bolt seal was its main feature. That's only part of its job. Its real value is that it acts as a passport. An ISO 17712-compliant bolt seal tells customs officials around the world, "This container has been secured according to an international security standard." This is its primary duty: to satisfy the legal and regulatory demands of cross-border shipping.

The Role of a Bolt Seal

- Primary Job: Compliance. It's built to pass international standards.

- Key Feature: A unique serial number on both the pin and the barrel, which must be recorded on shipping documents like the Bill of Lading.

- Strength: Must withstand specific shear, impact, and tensile pulling forces as defined by ISO 17712, requiring bolt cutters for removal.

Container Cable Seals: When Do They Become the Better Option?

Standard container doors are easy to seal, but what about a truck with overlapping canvas rings or a railcar with misaligned latches? A rigid bolt seal simply won't fit, leaving your cargo vulnerable.

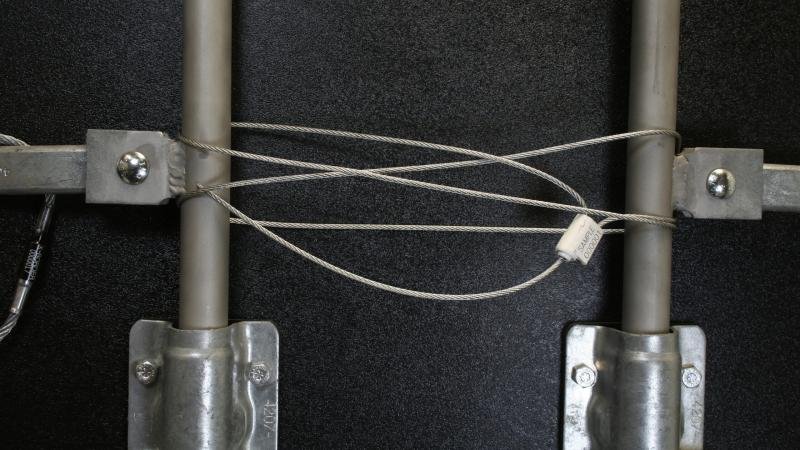

Cable seals become the better option when flexibility is required without sacrificing high security. Their main job is to provide compliant security for containers and transport assets that have irregular or hard-to-align locking points. Like bolt seals, high-security cable seals are also ISO 17712 compliant.

I remember a client who was transporting high-value machinery on a flat-rack container, covered by a tarp. The tie-down points were all in different places. A bolt seal was useless. We switched them to a 3.5mm high-security cable seal. The flexible steel cable could be threaded through all the tarp grommets and locking points, cinched tight, and secured. It fulfilled the same Compliance duty as a bolt seal but was versatile enough for an unconventional application.

| Scenario | Bolt Seal (Rigid) | Cable Seal (Flexible) |

|---|---|---|

| Standard Container Doors | Ideal | Good |

| Truck/Trailer Doors | Good | Ideal |

| Misaligned Hasps | Poor (Won't fit) | Ideal |

| Securing Tarps/Equipment | Impossible | Ideal |

What Defines a High Security Container Seal (HSS)?

The term "high security" is thrown around a lot. But without a clear standard, it's just a marketing buzzword that offers you no real legal or insurance protection if something goes wrong.

A true High Security Seal (HSS) is not defined by its look or material, but by its certification. It must be independently tested and certified to meet all the requirements of ISO 17712. The core duty of an HSS is to provide a globally recognized, standardized level of security and tamper evidence.

This standard is incredibly important, as it specifies not just a seal's physical strength, but also the security-related business processes of the manufacturer. To be ISO 17712 compliant, a seal must:

- Pass Physical Strength Tests: It must be strong enough to require substantial tools (like bolt cutters) for removal. The standard defines minimum resistance to tensile pull, shear, and impact forces.

- Display Tamper Evidence: The seal must be designed to clearly show signs of tampering. This is a core part of the "Clause 6" requirement.

- Be Marked with a Unique Identifier: Must have a unique serial number.

- Be Manufactured by a Certified Company: The seal provider's security procedures must also be audited and certified. This prevents seals from being "leaked" or counterfeited.

Without this formal certification, a seal is not a High Security Seal, no matter how strong it looks.

Barrier Seals: The Physical Defense for Your Container?

You're shipping extremely high-value goods like electronics or pharmaceuticals through a high-risk area. A simple plastic or even a standard bolt seal is not enough to deter organized criminals with time and tools.

Barrier seals are used when the primary job is no longer just compliance or evidence, but active physical defense. These heavy-duty devices are designed to physically stop or significantly delay unauthorized entry. They are made of thick, hardened steel and are much more formidable than standard seals.

Think of the difference this way: a bolt seal is like a standard lock on a house door. A barrier seal is like adding steel bars over the door itself. I worked with a client shipping goods through a region known for cargo hijacking. They were losing one in every fifty shipments. After they started using a combination of a bolt seal (for compliance) and a heavy-duty barrier seal (for defense), their losses dropped to zero. The barrier seal's job was simple: make the container such a difficult and time-consuming target that thieves would simply move on to an easier one. This strategy is a key part of layered security, also known as Defense in Depth.

Can Indicative Seals Be Used on Shipping Containers?

You have an empty container being moved from the depot to your warehouse. It doesn't need high security, but you want to make sure the doors aren't opened and used for illicit purposes en route.

Yes, indicative seals can be used on shipping containers, but only when their job is strictly to provide tamper evidence, not high security or regulatory compliance. These seals, often made of plastic or thin wire, are designed to be a visual deterrent and to break easily upon tampering, providing a clear indication that a breach occurred.

Indicative seals are perfect for low-risk, domestic, or empty container movements. Their role is to answer a simple question: "Has this been opened since it was sealed?" They cannot legally be used for international loaded shipments that fall under regulations like ISPS Code or C-TPAT. Using an indicative seal where a High Security Seal is required will result in your container being stopped, inspected, and re-sealed at your expense. It’s a classic case of using the wrong tool for the job.

Conclusion

Choosing the right container seal means matching the seal's core security duty—evidence, compliance, or defense—to your specific shipping scenario. It's not about the seal's shape, but about the job it performs.

Secure Your Shipment with the Right Tool from ProtegoSeal

Don't guess when it comes to securing your cargo. Whether you need an ISO 17712-compliant bolt seal for regulatory peace of mind or a flexible cable seal for a unique application, we can help. Contact us to ensure you have the right tool for the job.