You see a simple cable seal and wonder how it provides such high security. How can a flexible wire be pulled through a lock in one direction but become completely immovable the other way?

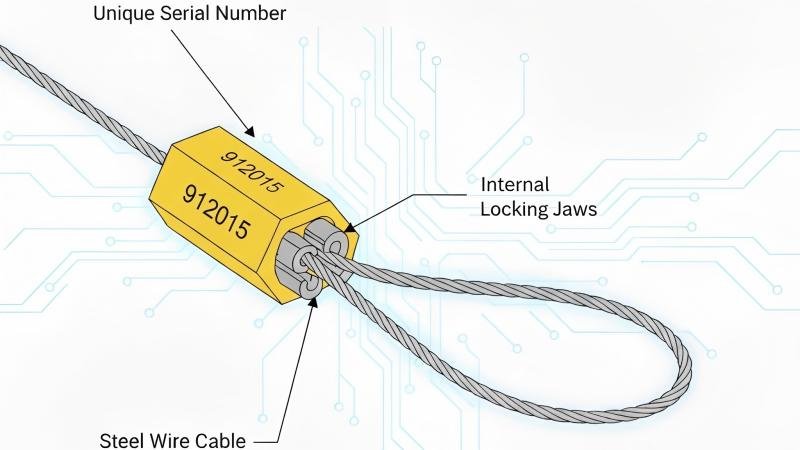

A cable seal works by combining a multi-strand steel cable with a single-use locking body. When the cable is pulled through the body, internal spring-loaded locking jaws or ball bearings wedge themselves into the braided grooves of the wire, creating a permanent, irreversible lock called a "mechanical interference self-lock."

This design is, in my opinion, one of the most clever in the security seal industry. It solves a unique problem that neither a bolt seal nor a plastic seal can. It combines the high-tensile strength of steel with the adaptability of a flexible cable. When a locking point is too awkward for a rigid bolt seal, but the security requirement is too high for a plastic seal, the cable seal is often the only and best solution.

The Synergy of a Flexible Cable and a Rigid Locking Body?

You're faced with securing two misaligned locking rings on a trailer door. A rigid bolt seal won't fit. A basic plastic seal isn't strong enough. This is the exact scenario the cable seal was designed to solve.

The genius of a cable seal is the perfect partnership between its two core components. You have a flexible, multi-strand steel cable that can snake through irregular or misaligned apertures. And you have a solid, hardened locking body that contains the high-security, one-way mechanism. This combination provides the best of both worlds: adaptability and strength.

I often explain it to my clients like this: think of the cable as the adaptable arms and the locking body as the unbreakable brain. The flexibility of the aircraft-grade steel cable means you can get a secure fit on everything from container doors and railway cars to valves and hatches. The rigid, numbered body ensures that once secured, that fit is permanent and can be audited through its unique serial number. This synergy is what makes it such a versatile problem-solver in the field.

The Pull-Tight Principle: Understanding Its Adjustable Lock?

Space and slack are a security risk. A seal or lock that fits loosely can be manipulated, rattled, or potentially bypassed. The goal is always to get the tightest fit possible.

The cable seal operates on a simple but highly effective "pull-tight" principle. After threading the cable through the locking points, you feed the end into the locking body and simply pull it until it's cinched down as tight as possible. There is no slack, no empty space, and no room for play. This adjustable length is a key security feature.

Unlike a bolt seal, which has a fixed locking length, a cable seal conforms perfectly to the application. This is a massive advantage. I’ve seen many situations where a tight fit is critical, for instance, on fuel tanker hatches, to prevent any prying or movement. The pull-tight action ensures the seal becomes one with the object it's securing. Once you pull it tight, the internal mechanism takes over, and that snug fit becomes permanent for the duration of its journey.

How Does the Internal Mechanism Grip and Deadlock the Wire?

You've pulled the cable tight. Now, what's happening inside that small metal body to create a lock so strong that it requires over 2,200 pounds of force to break?

The internal mechanism grips the wire using a concept I call "mechanical interference self-lock." Inside the locking body is a tapered channel containing hardened steel locking jaws (or sometimes ball bearings) held in place by a spring. When you pull the cable in, the jaws move aside to let the wire pass. But if you try to pull the cable out, the tapered channel forces the sharp jaws to bite deeper into the braided structure of the cable itself.

The Self-Locking Action

The key is that the lock uses the cable's own braided and twisted structure as part of the locking mechanism.

- Entry: As the cable tip enters, it pushes the jaws apart, allowing for smooth, one-way movement.

- Locking Attempt: When backward force is applied, the cable tries to pull the jaws with it.

- Wedging Action: The tapered walls of the channel force the jaws to clamp down harder and deeper into the grooves between the steel strands (interstices) of the cable.

- Deadlock: The more you pull, the deeper the jaws wedge, making the grip exponentially tighter. The cable's structure becomes the teeth that the lock bites into.

What Makes This One-Way Lock Irreversible?

You’re wondering if a thief could somehow "jiggle" the wire back out. Why is the grip considered permanent and single-use?

The lock is irreversible because of the precise engineering of the tapered channel and the hardness of the locking jaws. Any attempt to pull the wire backward only increases the bite force. There is no angle or trick that can release the pressure. The system is designed to fail into a locked state, not an unlocked one. Once those jaws have set into the cable's grooves, they cannot be retracted without destroying the internal mechanism. This is the core of its single-use design.

This irreversible design is a critical part of the chain of custody. It guarantees that the seal applied at the origin is the exact same one present at the destination. From a security standpoint, a seal that could be opened and re-closed would be useless. The irreversible nature of the cable seal's lock turns it into a reliable witness. Its job is not just to secure, but to provide a permanent record of that security.

How a Cut Wire Reveals Tampering Attempts?

The internal lock is too strong to defeat, so a thief’s only option is to cut the cable. How does this serve as a reliable form of tamper evidence?

A cut wire provides irrefutable proof of tampering for two simple reasons: the frayed steel cable cannot be reattached, and the unique serial number on the locking body prevents the seal from being replaced. To remove the seal, a thief must use cable cutters, which leaves a clean, sharp cut mark. The multi-strand cable will also fray at the cut point, making any attempt to glue or weld it back together obvious upon inspection.

This is the final piece of the security puzzle. The lock is too strong to pick, so brute force is the only option. But that brute force leaves a permanent, highly visible scar. When the receiving party inspects the container, they don't just check for the presence of a seal. They check two things:

- Does the serial number on the seal match the number on the manifest?

- Is the cable intact and un-cut?

If the answer to either question is "no," the chain of custody is broken, and a security investigation is triggered immediately.

Conclusion

A cable seal works by using a one-way locking mechanism that wedges into the cable's own structure, creating an irreversible, adjustable, and high-strength barrier perfect for versatile applications.

Solve Your Complex Security Challenges with ProtegoSeal

When standard seals don't fit, you need a smarter solution. The high-security, ISO-compliant cable seals from ProtegoSeal offer the perfect blend of strength and flexibility for your most challenging applications. Contact us to secure your assets without compromise.