Trying to find a single invention date for tamper-proof seals can be frustrating. The real answer is more fascinating than one date. Let's pinpoint the first modern seal and uncover its true 4,000-year origin story.

The first patented, modern tamper-proof seal came out in the 1870s, invented to secure railway boxcars. However, the fundamental concept of using a fragile device for tamper evidence is ancient, dating back over 4,000 years to clay and wax seals in Mesopotamia and Egypt.

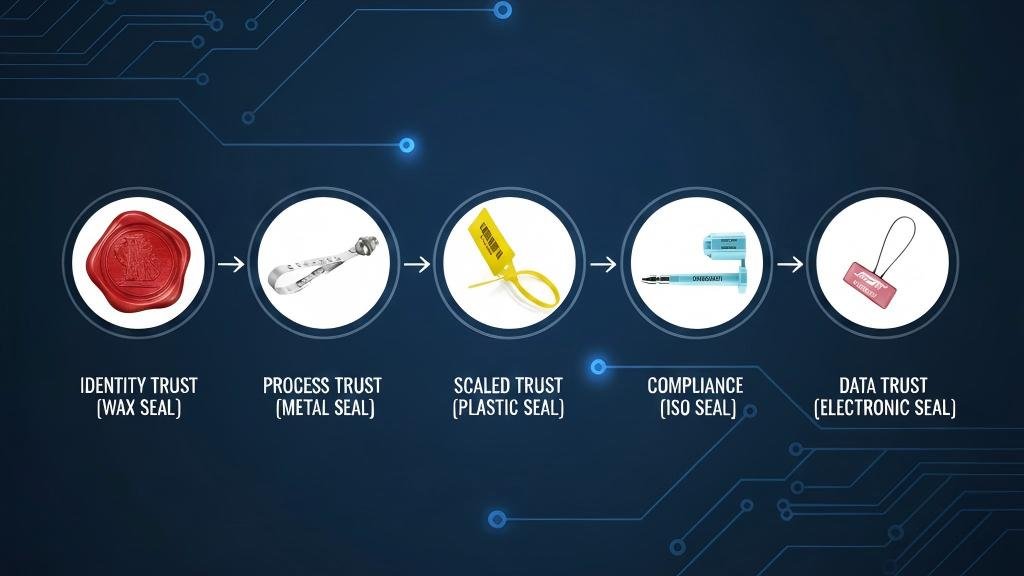

So, while we have a clear date for the first patented device, the story is far bigger. This isn't just a history of technology; it's a history of how trust itself had to be reinvented as trade expanded. As the distance between a seller and a buyer grew, the nature of that trust had to change, and with each change, a new "first" seal was born.

Tracing the Source: Ancient Prototypes of Tamper-Proof Seals?

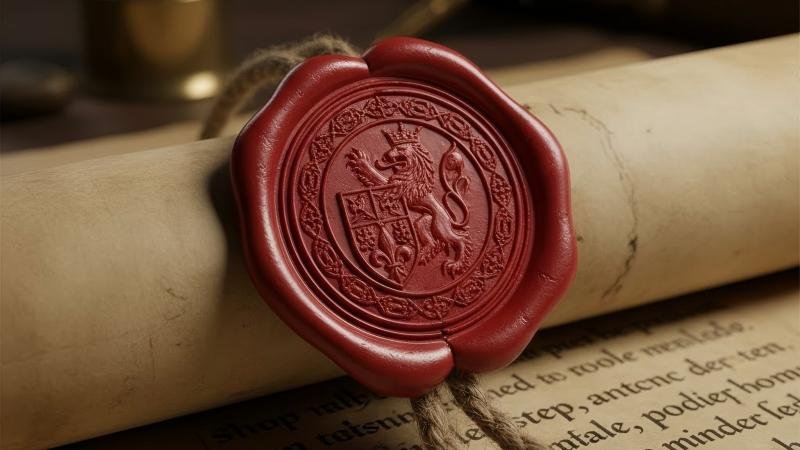

Imagine sending a valuable scroll across the kingdom. How could the recipient be certain it was authentic and unread? This was a challenge for ancient rulers who relied on trust over short, controlled distances.

The earliest prototypes, like Mesopotamian clay seals and Roman wax seals, were not about physical prevention. They provided "Identity Trust." Stamped with a unique signet, the seal’s purpose was to verify the sender's authority. A broken seal didn't mean a lock was picked; it meant a king's word was broken.

These early seals were perfect for their time because the "trust distance" was relatively short—the length of a courier's journey within an empire. The economy was based on personal authority and known relationships. The seal's job was to project the sender's identity across that distance. It was a physical representation of a person's word. I often point this out to clients: the very first seal was essentially a business card you couldn't fake.

The Role of Identity in a Short-Distance World

In an era before mass logistics, trust was personal. The seal solved a specific problem:

- The Challenge: How to prove a message is from a specific person (a king, a noble) and hasn't been altered.

- The "Trust Distance": From the sender's desk to the recipient's hands.

- The Solution: An intricate, personal mark (like a signet ring) pressed into a fragile material. This seal carried the sender's authority. It was a one-to-one form of trust, verifying who sent the item. It was never about securing millions of items, but about authenticating a single, important one.

The 19th Century: Birth of the First Patented Tamper-Proof Seal?

The Industrial Revolution changed everything. With railways stretching across continents, goods were now handled by dozens of anonymous workers. Personal trust between the sender and receiver was completely lost.

This medium-distance trade created a new challenge, leading to the birth of the modern lead-and-wire seal in the 1870s. Its revolutionary feature wasn't the metal, but the sequential number. For the first time, trust shifted from a person to a system. This was the dawn of "Process Trust."

This leap is something I constantly emphasize. The question was no longer, "Did the king seal this?" It became, "Is this the same seal, #1001, that was applied in Chicago?" The patent for the first modern seal wasn't just protecting a device; it was protecting a new method of accountability. The trust was now placed in the integrity of a documented process, not the integrity of an individual handler.

The Rise of Process in a Medium-Distance World

Railways created a new "trust distance" that was longer and involved multiple unknown parties.

- The Challenge: How to ensure goods aren't stolen or swapped when passing through the hands of anonymous railway and warehouse workers.

- The "Trust Distance": From a factory in one city to a distributor in another, connected by rail.

- The Solution: A durable seal with a unique, factory-stamped serial number. This number was logged in a manifest. The trust object shifted from the person to the process. Verification was simple: check if the number on the seal matches the number on the paper. This brought accountability to an anonymous system.

How Did Plastic Tamper-Proof Seals Evolve in the 20th Century?

Following World War II, globalization took off. The intermodal container became the backbone of a new global economy. The sheer volume of goods being shipped was staggering, and the "trust distance" became oceanic.

This explosion in volume and distance required a new kind of trust: "Scaled Trust." Expensive, slow-to-apply lead seals were unworkable. The solution was the plastic pull-tight seal—cheap, mass-producible, easy to apply, and reliable enough for the massive scale of containerized shipping.

The genius of the plastic seal was its accessibility and simplicity. Suddenly, providing tamper evidence wasn't just for high-value railway cars; it could be applied to everything from airline catering carts to individual tote boxes. It democratized security. I've worked with companies that went from sealing zero assets to sealing thousands per day, simply because plastic seals made it economically feasible. This innovation allowed procedural trust to be scaled up for the new global marketplace.

Trust for a Long-Distance, High-Volume World

Containerization created the longest "trust distance" yet, both physically and in the number of handover points.

- The Challenge: How to provide basic, affordable tamper evidence for millions of containers and assets crossing the globe.

- The "Trust Distance": Across oceans and continents, from a factory in China to a retail store in Europe.

- The Solution: A low-cost, single-use plastic seal with an internal locking mechanism. Its value wasn't in its strength, but in its ability to provide a cost-effective, visible indicator of tampering that could be deployed at an unprecedented scale. It was the key to making Process Trust affordable for everyone.

The ISO 17712 Standard and the Rise of Modern High-Security Seals?

The 9/11 attacks revealed a terrifying vulnerability in the global supply chain. It was no longer enough for trust to be cheap and scalable; it needed to be verifiable and standardized across borders.

This new reality gave birth to "Compliance Trust." It wasn't driven by commercial loss, but by global security risk. The creation of the C-TPAT program and the ISO 17712 standard created a universal benchmark for high-security seals, like bolt seals. Now, trust was defined by adherence to an international standard.

I remember this shift well. The conversation with clients changed overnight. It was no longer "What seal do you recommend?" but "Which of your seals is C-TPAT compliant and meets ISO 17712 'H' class?" A seal's value was now measured by its certification. This standard allowed a customs officer in one country to trust a seal that was applied in another, without ever needing to know the company that applied it. It was trust based on a shared, global rulebook.

The Need for Trust Over Standardized Distances

In a post-9/11 world, every international shipment became part of a global security network.

- The Challenge: How can governments and corporations worldwide trust the security of a container sealed by an unknown entity in another country?

- The "Trust Distance": A global, standardized distance where every link in the chain must meet the same security criteria.

- The Solution: The high-security bolt seal, engineered to meet specific, testable physical strength standards (ISO 17712). This created Compliance Trust. A compliant seal is a declaration that a shipment meets a global security baseline, facilitating faster customs clearance and building confidence in the entire system.

When Did Electronic Tamper-Proof Seals Kickstart the Digital Era?

Today, knowing a seal was broken upon arrival is no longer enough. Businesses demand to know when and where it was broken. The "trust distance" is no longer physical; it's temporal. We need trust in real-time.

This demand for immediate information sparked the latest evolution: the electronic seal. By integrating GPS, cellular, or RFID technology, these seals provide "Dynamic Data Trust." They transform the seal from a passive object that is inspected at the end of a journey into an active data node that reports its status throughout the journey.

This is the frontier I'm working on with my most forward-thinking clients. We are moving from forensics—finding out what went wrong—to prevention and real-time response. An e-seal doesn't just tell you a door was opened; it sends an instant alert to your phone with GPS coordinates the second it happens. This isn't just an evolution; it's a revolution in accountability. The trust is now placed in a live, unalterable stream of data.

Trust at the Speed of Data

In the modern digital supply chain, delays in information are as costly as physical losses.

- The Challenge: How to get immediate, actionable information about the status and location of high-value assets anywhere in the world.

- The "Trust Distance": Real-time. The gap is not between places, but between an event happening and you knowing about it.

- The Solution: An electronic seal that combines a physical barrier with digital tracking technology. This provides Dynamic Data Trust. It offers live updates on location, seal status (locked/unlocked), and environmental conditions, closing the information gap and allowing for immediate response to any security breach.

Conclusion

The tamper-proof seal was never invented on a single day. It has been reinvented continuously for 4,000 years, each time to solve a new trust challenge created by the ever-expanding distance of trade.

Bridge Your Trust Distance with ProtegoSeal

Whether your challenge is process, compliance, or real-time data, your trust protocol needs the right tool. ProtegoSeal offers a complete range of seals, from ISO 17712 compliant bolt seals to advanced tracking solutions, designed for modern trust challenges. Contact us to secure your supply chain.