The manifest says security seal #12345, but the seal on the container reads #12348. The numbers look legitimate, but the discrepancy brings your entire logistics chain to a screeching halt. Is it a typo, or has someone expertly altered the barcode to misdirect a shipment?

This single point of failure can compromise your entire tracking system, leading to lost assets, customs delays, and a complete breakdown of accountability. Your security is only as strong as the integrity of that tiny number.

You prevent barcode tampering by making the number an inseparable part of the security seal itself. Through advanced engineering, the barcode is integrated into the seal's material and structure, ensuring that any attempt to alter it will cause obvious, irreversible damage to the seal body.

This isn't theoretical. I once consulted for a fuel transport company facing significant losses. They discovered that drivers were using heat guns and fine tools to subtly alter the last digit on their plastic seals' printed barcodes. A truck meant for Depot A would be diverted to an unauthorized location, and the altered seal number would still be logged as a "valid" scan. Their problem wasn't the seal's lock; it was the vulnerability of the printed number. We solved it not by adding more security guards, but by changing the seal itself. This experience taught me that preventing tampering is about smart design, not just surveillance.

Why Is Laser Engraving the Core of Barcode Permanence?

You've seen seals with barcodes that are just printed on with ink, or worse, on a paper sticker. What makes a laser-engraved barcode fundamentally more secure and worth the investment?

Relying on a surface-level sticker or simple ink is like putting a cheap padlock on a bank vault. A determined attacker can peel, scratch, or use solvents to remove the number, creating an opportunity to apply a fake one.

Laser engraving is preferred because it doesn't add a layer of ink on the seal; it creates the barcode by physically and chemically altering the seal's material itself. This surface integration makes the barcode a permanent, non-removable feature of the seal.

The essence of this process is that the barcode becomes one with the product. Let's break down why this is so effective:

- Permanence: The laser burns the marking deep into the plastic or metal. There is nothing to peel or scrape off. To remove the barcode, you would have to physically grind away a significant portion of the seal's body, which is an immediate and obvious sign of tampering.

- High Contrast & Durability: The process creates a sharp, clear mark that resists abrasion, UV light, and chemicals. An ink-printed barcode can fade in the sun or be washed away by solvents, but a laser-marked one remains readable throughout its journey.

- No Added Materials: Unlike stickers, there are no adhesives that can fail in extreme heat or cold. The barcode is as durable as the seal material itself.

By choosing laser engraving, you are moving from simply "labeling" a seal to truly "identifying" it in a permanent, secure way.

How Does a Seal's Structural Design Physically Block Tampering?

Even with laser engraving, what stops someone from taking a tool and scratching out the number? How can the physical shape of the seal add another layer of defense?

A flat, exposed surface is an open invitation for an attacker. If a barcode is easy to get to, it's easy to attack, no matter how well it's marked. This is a failure of physical design.

A well-designed security seal uses "structural traps"—raised walls or recessed surfaces—to physically block access to the barcode. This simple but effective approach makes it incredibly difficult to apply a tool to the barcode's surface without leaving obvious collateral damage.

This is a core principle of good security engineering: make the target difficult to reach. The design should force the attacker to damage the seal in their attempt to alter the number. Here are some common structural protection methods:

- Raised Protective Ridges: Thick plastic walls are molded around the barcode area. A knife or screwdriver can't get a flat angle on the barcode without first gouging these protective walls.

- Recessed Windows: The barcode is placed inside a sunken cavity on the seal body. This puts the marking out of reach of direct scratching or abrasion.

- Curved Surfaces: Placing the barcode on a highly curved surface makes it almost impossible to alter digits consistently or to apply a counterfeit sticker flatly over the original.

These "structural traps" don't make tampering impossible, but they make it so difficult and messy that it's no longer a viable method of attack. The goal is to ensure any tampering attempt is immediately self-exposing.

How Does the Seal's Material Make Tampering Attempts Obvious?

You are choosing between seals made of different plastics, but how does the material itself become an active security feature that reveals tampering with the barcode?

It's easy to assume all plastics are the same. But the right material science doesn't just resist damage; it actively exposes it. The wrong choice can allow an attacker to hide their work.

The seal's material is the foundation of its tamper evidence. A well-engineered polymer doesn't just hold the barcode; it's designed to change its appearance permanently when attacked, a concept known as material embodiment.

Think of the material as a canvas that screams when it is scratched.

- Dual-Layer Color Reveal: This is a highly effective technique. The seal is made with co-extruded plastic—a colored outer layer over a bright, contrasting inner core (e.g., blue over white). Any attempt to scratch, cut, or shave the barcode surface immediately scrapes away the outer layer, exposing the bright inner color. This creates an unmissable visual alert.

- Stress Mark Indication: Polymers like Polypropylene (PP) are chosen for their tendency to show stress marks. When bent or twisted, the plastic permanently discolors to a chalky white, leaving a clear history of physical tampering.

- Hardness and Brittleness: Harder plastics like ABS are used in high-security seals. They are resistant to simple scratches, and a more forceful attack will cause the material to fracture or chip in a way that is jagged and impossible to conceal.

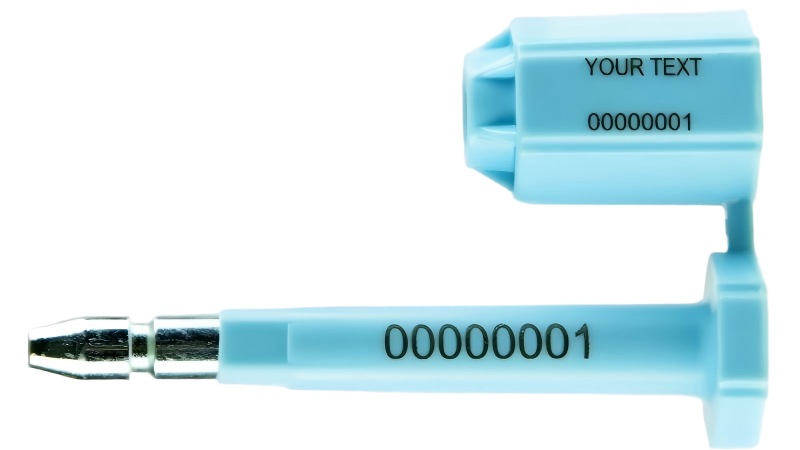

How Can Matching Numbers on a Bolt Seal Prevent Sophisticated Tampering?

An attacker replaces the entire locking barrel of a bolt seal with a counterfeit one bearing a fake number. How do you prevent this advanced attack that bypasses surface-level scratching?

A simple seal relies on a single marking. If an attacker can replicate or replace the part that holds that single number, your entire security system fails. This is a critical vulnerability for two-part seals.

To prevent this, high-security bolt seals have the unique barcode and serial number laser-engraved on both separate components—the pin and the barrel. This "forced redundancy" prevents tampering by making a successful deception exponentially harder.

This method transforms a simple inspection into a powerful verification process. An attacker can't just alter one number; they must now perfectly replicate a unique, laser-engraved marking on two distinct parts and materials—hardened steel and ABS plastic. The logistical complexity and cost for the attacker become prohibitively high, effectively preventing the attempt.

| Vulnerability | Insecure Single-Marked Seal | Secure Matched-Number Seal |

|---|---|---|

| Component Swap | Attacker can swap the barrel with a fake. | Swap is useless. Numbers won't match. |

| Verification | Hope the number looks correct. | Cross-verify that pin and barrel numbers match. |

| Prevention Method | None. | Deters attack by making it too complex and costly. |

This isn't just about detection; it's a preventative measure. Knowing that any inspection will instantly reveal mismatched numbers acts as a powerful deterrent against tampering in the first place.

Why Is Making Tampering Obvious the Ultimate Prevention Strategy?

So, we have laser engraving, structural traps, advanced materials, and matching numbers. How do these elements work together as a single, coherent security philosophy?

You might think the goal is to create an indestructible seal. But a determined attacker with enough time and tools can damage anything. This is a flawed approach to security.

The ultimate prevention strategy is not indestructibility; it's making tampering self-exposing. A truly secure design philosophy ensures that the very act of attempting to tamper with the barcode number causes such obvious, irreversible damage that the attempt is guaranteed to be discovered.

This is the principle that ties everything together.

- Laser engraving forces the attacker to physically damage the seal's body.

- Structural traps force them to create collateral damage to the surrounding area.

- Tamper-evident materials make that damage visually obvious.

- Matching numbers prevent component swapping, forcing the attacker back to these messy, exposure-prone methods.

The system is designed so there is no such thing as a "neat" or "subtle" tampering attempt. This is the most powerful deterrent of all, as it removes the attacker's primary weapon: deception.

Conclusion

Preventing barcode tampering is not about finding an "un-scratchable" surface. It's about smart engineering that makes the barcode an integral part of the seal and ensures any attempt to alter it results in the seal's obvious self-destruction, exposing the attacker.

Engineer-Grade Security Seals from ProtegoSeal

Is your security process vulnerable to number tampering? Upgrade from simple printed labels to seals with deeply integrated, tamper-exposing barcodes. ProtegoSeal manufactures security seals using advanced laser engraving, structural design, and material science to make your barcode's integrity absolute. Contact us to get the physically robust security seals your assets deserve.