"The driver says the seal was intact; the port says it wasn't." You’re caught in a frustrating cycle of finger-pointing, and your business is the one absorbing the loss.

This endless cycle of blame isn't just an annoyance; it's a critical failure of your tracking process. Without data-driven proof, you have no way to assign responsibility, leaving your entire operation exposed to repeated risks.

The best way to track a shipment with a barcoded security seal is to build a disciplined Chain of Custody. This is a management system where every handover is a mandatory scan event, creating a complete, auditable digital trail that assigns clear responsibility at every step.

I once worked with a client in the food export business who learned this the hard way. They had scanners and barcoded security seals, but their process was informal. A container of high-value frozen goods was rejected at port because its temperature logs were incomplete. They knew it left their facility fine, but they couldn't prove it wasn't mishandled by the transport company. The carrier's driver claimed "the seal was already on when I picked it up." My client had no timestamped scan event tied to that specific driver's ID to prove otherwise. They suffered a $70,000 loss not because of a tech failure, but a discipline failure. This is why we must talk about process, not just products.

Why Must You Assign a Unique Barcoded Security Seal to Each Shipment?

A truck is leaving the loading dock, and a worker grabs a barcoded security seal and applies it. But is that action being recorded? Is the seal's unique number linked to this specific shipment in your system?

Without this first critical step, the barcode on your security seal is just a random number. It has no context, no connection to the asset it's supposed to protect, rendering all future tracking efforts meaningless.

The best tracking begins the moment you digitally associate a unique barcoded security seal with a specific shipment's data. This act is the "birth certificate" of your Chain of Custody, transforming a physical object into a trackable digital asset before it even starts moving.

This initial assignment is the foundation of accountability. It's not enough to just apply the security seal. The "best way" requires a disciplined process where the operator's scan does more than just record a number. At our factory, when we formalize this process, we stress that this scan must create a complete "event record."

| Poor Practice: "Just Record the Number" | Best Practice: "Create an Event Record" |

|---|---|

| Security Seal #1234567 is used. | Security Seal #1234567 assigned to Shipment ID #SH9876. |

| The log shows the seal is on a truck. | Log shows applied by Operator ID #E542. |

| At Warehouse Dock B on [Date/Time]. | |

| For Customer: XYZ Corp, PO#: PO-123. |

This isn't a technology problem; it's a management procedure. By enforcing this level of detail from the very beginning, you've already established who is responsible for the shipment's integrity as it leaves your control.

How Do You Set Up Your System to Read and Log the Barcoded Security Seal Data?

You have scanners and barcoded security seals, but your data ends up in isolated spreadsheets. How do you build a system that turns individual scans into a single, coherent tracking history?

If scans are just numbers on a list an employee emails at the end of their shift, you don't have a tracking system. You have a recipe for confusion, delays, and a log that's useless in a real-time crisis.

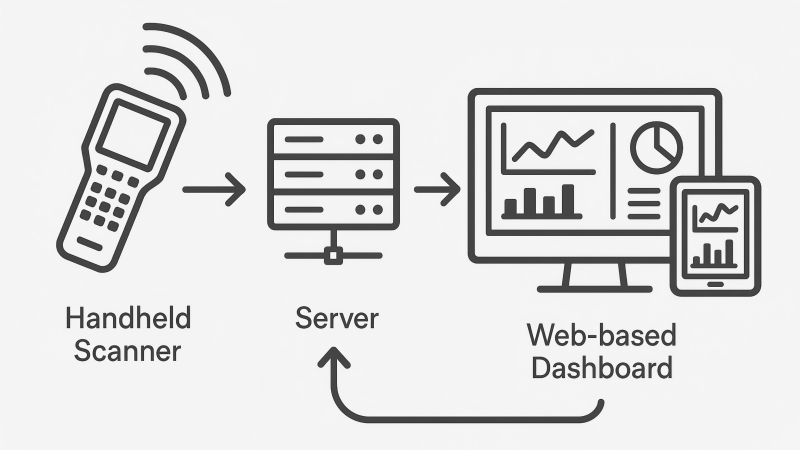

Set up your system so that every scan is automatically uploaded to a central database in real-time. Each log entry must include not just the security seal's number, but also the "who, when, and where"—the User ID, a timestamp, and the GPS location of the scan.

The goal is to eliminate manual data entry and create an unimpeachable record. A powerful system doesn't have to be expensive, but it must be centralized. Here's what that looks like in practice:

- Hardware: Use scanners with Wi-Fi or cellular connectivity. A simple smartphone app can often do the job perfectly if a dedicated device isn't necessary.

- Software: Your scanning app should force the user to log in. This automatically captures the "who." It should then transmit the seal number, user ID, and the device's current time and location to a central server.

- The Golden Rule of Data: The system must not allow operators to manually edit the timestamp or location data. The integrity of your audit trail depends on this.

This central log becomes your "single source of truth." When an issue arises, you aren't digging through different people's paper logs; you are looking at a complete, chronological history of every touchpoint. This is how a simple scan evolves into an evidence-based event audit.

At Which Key Checkpoints Must the Barcoded Security Seal Be Scanned in Transit?

Your shipment is on its way, moving between trucks, warehouses, and ports. How do you maintain the integrity of your tracking log and ensure accountability during this vulnerable phase?

A common mistake is to only scan at the beginning and the end of a journey. This creates a massive "black hole" where anything could happen, leaving you with no one to hold responsible if a problem occurs mid-transit.

The barcoded security seal must be scanned at every single handover point. A handover is any moment when responsibility for the shipment transfers from one party or location to another. These are the mandatory checkpoints that form the links of your Chain of Custody.

The purpose of these scans is not to "track the location"—GPS does that better. The purpose is to document the transfer of liability. Each scan is a digital handshake that says, "I, [User ID], confirm that I have received this shipment with barcoded security seal [Seal Number] intact at this [Date/Time/Location]."

Your operational discipline must enforce scans at these critical checkpoints:

- Leaving the Facility: The driver scans the security seal as they accept the load.

- Arriving at a Port/Hub: The port authority or warehouse staff scans the security seal upon entry.

- Departing from a Port/Hub: A new driver scans the security seal as they take possession.

- Intermediate Handover: Any time the trailer or container is switched to a new carrier.

Missing even one of these scans breaks the chain. A strong process makes it clear: no scan, no handover. This simple rule forces accountability and deters internal theft or negligence far more effectively than any passive tracking device.

What Actions Should You Take When Your Barcoded Security Seal's Data Shows an Exception?

A driver calls to report a broken security seal, or a scan shows up in an unexpected location. What is your immediate, systematic response?

Panic and disorganized phone calls are the wrong answer. Without a clear, pre-defined protocol, an exception event can quickly spiral into a major loss as evidence disappears and stories change.

![]()

When an exception occurs, you must immediately execute a pre-defined Incident Response Plan. The protocol's first step is to secure the asset and document everything. The goal is to preserve evidence for investigation and resolution, not to fix the problem on the fly.

An exception is any deviation from the expected process. This could be a broken security seal, a missing scan at a checkpoint, or a seal number that doesn't match the manifest. Your response plan should be a simple checklist that every team member understands.

Immediate Action Protocol:

- Do Not Move: The driver or operator must not move the shipment further. The location of the incident is a critical piece of evidence.

- Document Immediately: The operator must take clear photos of the security seal (or lack thereof), the container doors, and the surrounding area.

- Report to Central Command: The operator immediately calls a designated security manager to report the incident, providing the shipment ID and their location.

- Log the Exception: The security manager logs the exception in the central tracking system, creating a permanent record of the incident, the time it was reported, and the initial details.

- Apply Secondary Seal (If Instructed): Only after receiving explicit instructions from the security manager can a secondary, documented "breach seal" be applied to secure the asset for further movement.

This disciplined, systematic approach turns a chaotic event into a controlled, evidence-gathering process. It protects your company by ensuring you have the data needed to file claims, address security lapses, and assign responsibility accurately.

Why Is the Final Scan at Delivery a Critical Step in the Tracking Process?

The shipment has arrived, and the customer is waiting. The driver breaks the security seal and opens the doors. Is the job done?

If you skip the final scan, you are destroying the most important piece of evidence in your entire tracking process. You are voluntarily breaking the last link in your Chain of Custody and losing the ability to prove you fulfilled your obligation.

The final scan at delivery, performed by the recipient before the security seal is broken, is the critical step that closes the loop on the Chain of Custody. It is your definitive, timestamped proof that you delivered the shipment intact and successfully transferred responsibility to the customer.

This final scan is your legal and operational shield. It's the moment the recipient formally agrees, "I am accepting this shipment, and I confirm the barcoded security seal you applied, number 1234567, was present and intact upon arrival."

I once helped a client win a $25,000 claim dispute because of this simple step. Their customer claimed a pallet of electronics was missing from a delivery. My client pulled up their tracking log, which showed the consignee's own warehouse manager had scanned the original security seal upon arrival. The timestamp on that scan proved the shipment was secure when it entered the customer's property. The loss had occurred after delivery. Without that final, disciplined scan, it would have been my client's word against theirs. This is why the process isn't over until that final scan is logged.

Conclusion

The best way to track with a barcoded security seal is to embrace discipline over technology. By building a robust Chain of Custody with mandatory scans at every handover, you transform tracking from a passive location finder into an active system for enforcing accountability and deterring risk.

Build Your Chain of Custody with ProtegoSeal

A strong process needs a reliable product. Your Chain of Custody is only as strong as the physical security seals you use. ProtegoSeal provides high-quality, clearly marked barcoded security seals designed for durability and readability in demanding environments. Contact us to get the dependable seals you need to build a tracking system based on discipline and accountability.