You're using security seals with serial numbers, but your logbooks are messy and data entry is slow. You look at your team manually writing down long strings of digits and wonder, "There has to be a better way."

This manual process is a ticking time bomb. A single typo or a lazy entry can create a phantom "missing" container, leading to wasted man-hours on audits and creating breaches in your security protocol that you won't discover until it's too late.

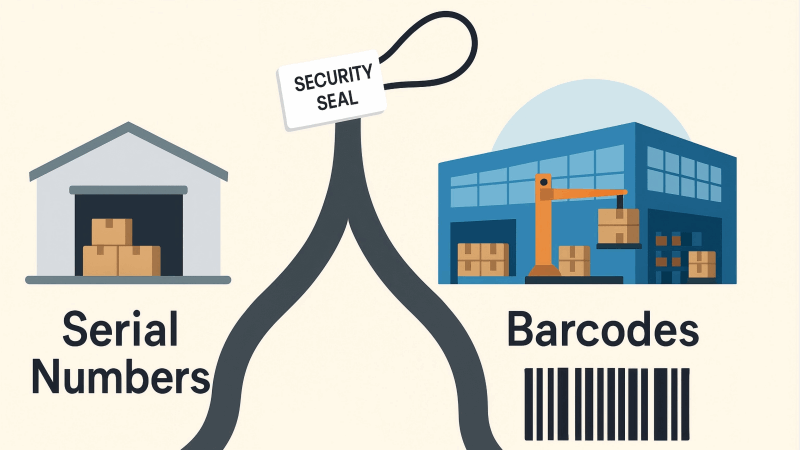

The answer depends on your process. A serial number is enough for basic, manual visual checks. However, if you need to quickly and accurately get your seal's information into a digital system, you absolutely need a barcode. It’s the difference between human-based and machine-based data entry.

I'll never forget a call from a logistics manager for a major retailer. He had his entire team working over a weekend, physically checking hundreds of trailer seals in their yard. Why? Because someone had written down a ‘5’ instead of an ‘S’ on a log sheet, and their system showed a high-value trailer as unsecured for 48 hours. The panic and cost that a single character caused was immense. This incident perfectly illustrates the core of our discussion today. Your choice isn't just about a number or some black and white lines; it's a fundamental decision between a process designed for human eyes and one designed for machine efficiency.

What Is the Core Function of a Serial Number: When Is It Enough?

You look at a security seal and see a unique, sequential number. It serves a clear purpose, so why complicate it? Is this basic feature sufficient for your needs?

For small-scale operations, adding barcodes can feel like an unnecessary expense. If your process works, why change it now?

The core function of a serial number is to be a unique identifier. It confirms a seal's identity for manual, low-volume checks. It is enough when you don't need digital tracking and your security relies on visual confirmation and simple logs.

This is the classic, time-tested approach. It's designed for a human-centric workflow. An operator walks up to a container, reads the number on the seal, and compares it to the number written in a logbook or a simple spreadsheet. It’s a one-to-one verification. A serial number is perfectly adequate when:

- Volume is Low: You're sealing and checking a handful of assets per day.

- Digital Integration isn't Required: You don't use a Warehouse Management System (WMS), ERP, or any other digital tracking software.

- The Goal is Simple Verification: Your primary need is to confirm that the seal applied at origin is the same one present at the destination, not to track its journey in real-time.

In these cases, the serial number does its job perfectly. It provides a unique "fingerprint" for that specific seal, fulfilling the basic requirements of a security protocol.

How Do Barcodes Revolutionize Security Seal Tracking and Management?

Your team is spending too much time on data entry, and you're constantly finding errors in your tracking logs. How can you eliminate these mistakes and speed up the entire process?

Manual tracking is not just slow; it's fundamentally unreliable. Every human touchpoint is a potential point of failure, risking the integrity of your entire supply chain.

Barcodes revolutionize tracking by enabling instant, error-free data capture with a scanner. This automates logging, integrates seamlessly with management systems, and transforms a physical seal from a static object into a real-time digital asset.

This is where we shift from a process designed for humans to one designed for machines. A barcode contains the same serial number data, but it presents it in a language that a computer can read instantly and perfectly every single time. This is a game-changer for any operation that is scaling up. The "revolution" comes from three key benefits:

- Speed: A scan takes less than a second. Manually reading, cross-checking, and writing a 7-digit number can take 30 seconds or more. Across hundreds of seals, this time saving is enormous.

- Accuracy: Scanning has an error rate of virtually zero. Manual data entry error rates can be as high as 1 error for every 300 characters. This eliminates typos, transposed numbers, and legibility problems.

- Integration: This is the most powerful part. The scanned data can be fed directly into your Warehouse Management System (WMS) or enterprise software, automatically updating inventory status, location, and chain of custody records without a single manual keystroke.

Beyond Scan Speed, What Are the Hidden Advantages of Barcodes Over Serial Numbers?

You understand that scanning is faster and more accurate. But are there other, less obvious benefits that might justify the switch to barcodes for your security seals?

Focusing only on speed might cause you to underestimate the full operational value that barcodes can unlock. The true advantages lie in the data and accountability they enable.

Beyond speed, barcodes provide hidden advantages like enhanced data capacity, improved accountability, and the automatic creation of a robust audit trail. This turns your security seal into an active part of your management and compliance infrastructure.

Once you start thinking of a barcode as a gateway to data, a whole new world of benefits opens up. In my experience, these are the "aha!" moments for my clients:

- Enhanced Data Capacity (2D Barcodes): While a simple 1D barcode (like the ones on groceries) holds just the serial number, 2D barcodes (like QR codes) can hold much more information. You could embed the seal type, manufacturing date, shipment number, or even a destination address directly into the seal itself.

- Improved Employee Accountability: When an operator scans a seal, the system can automatically log the user ID, timestamp, and GPS location of the scan. This creates a clear record of who handled the seal and when, significantly reducing the risk of internal tampering or negligence.

- Streamlined Compliance: For industries with strict chain of custody requirements (like pharmaceuticals or high-value goods), barcodes automate the documentation process, making audits smoother and less stressful.

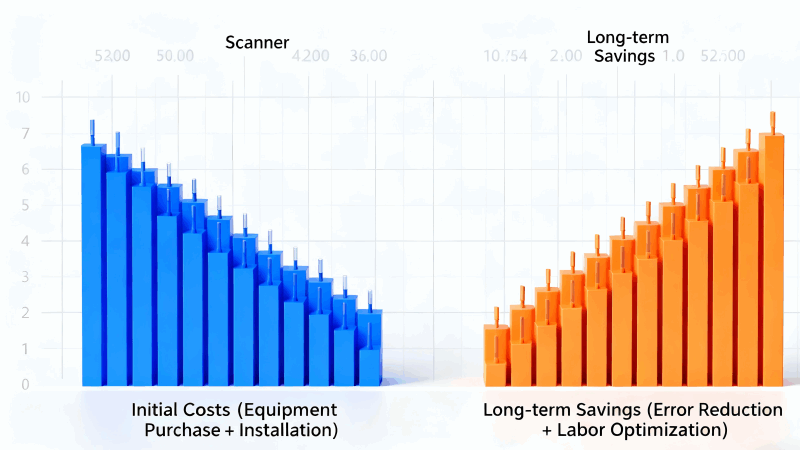

Cost Comparison: Is the Extra Investment in Barcodes Truly Worthwhile?

You see the benefits, but your budget is tight. Barcoded seals and scanners represent an upfront cost. How do you know if the return on investment will be positive for your business?

It's easy to see the immediate cost on an invoice. It's much harder to quantify the hidden costs of not upgrading—the wasted labor, the cost of fixing errors, and the potential losses from security breaches.

While barcoded seals have a slightly higher unit cost, the investment is almost always worthwhile if you handle a moderate-to-high volume of seals. The ROI comes from drastically reduced labor costs, the elimination of costly errors, and improved operational efficiency.

Let's break it down with a simple, practical analysis I often walk through with my clients.

- Direct Costs:

- Serial Number Only: The base price of the seal.

- Barcode: The base price + a small premium for printing the barcode. You also need scanners (a one-time hardware cost).

- Hidden Costs of Staying with Serial Numbers:

- Labor Cost: Calculate the time your employees spend manually writing, checking, and entering numbers into a system. Multiply that by their hourly wage. This is a significant, recurring operational expense.

- Cost of Errors: What is the cost of one "lost" container? Think about the man-hours for the audit, potential penalties for shipping delays, and the value of the goods at risk. One major error can easily cost more than your entire scanner investment.

When you factor in these hidden costs, the math almost always favors barcodes for any business beyond a very small scale.

When Should You Choose Serial Numbers, and When Is It Time to Upgrade to Barcodes?

You understand the pros and cons of both systems. Now it's time for a decision. How do you draw the line and decide what is right for your operation today and for your growth tomorrow?

Making the wrong choice can either leave you stuck with an inefficient, error-prone system or cause you to overspend on a solution you don't fully need yet.

Choose serial numbers for low-volume, manual-logging environments. It's time to upgrade to barcodes the moment you need to integrate seal data with a digital system, when manual entry errors start causing problems, or when your operational volume makes manual logging a significant bottleneck.

Here is the simple decision framework I use to guide my clients:

| You Should Stick with Serial Numbers If: | You Should Upgrade to Barcodes If: |

|---|---|

| You manage fewer than 20-30 seals per day. | You manage a high volume of seals daily. |

| Your record-keeping is a physical logbook or simple spreadsheet. | You use or plan to use management software (WMS, ERP, etc.). |

| Your primary security need is simple point-to-point verification. | You need a detailed, real-time audit trail and chain of custody. |

| Your team is small and operations are centralized. | Your operations are distributed across multiple sites or teams. |

| Data entry errors are rare and have a low impact. | A single data entry error causes significant financial or operational pain. |

Ultimately, serial numbers look to the past, verifying what happened. Barcodes look to the future, enabling real-time management and data-driven decisions.

Conclusion

The choice is clear: serial numbers are for human-led visual checks, while barcodes are for machine-driven data integration. Upgrading to barcodes isn't an expense; it's an investment in speed, accuracy, and a smarter, more efficient security operation.

Ready to Automate Your Security Process?

Eliminate costly errors and save valuable time. At ProtegoSeal, we can help you implement the right security seal solution, whether that's a high-security barcoded seal or a custom solution for your specific needs. Contact us to build a faster, more accurate, and more secure tracking system.