You see the phrase "ISO 17712 Certified" everywhere when buying high-security seals. It feels like just another technical label, tempting you to wonder if a cheaper, non-certified seal might do the job just fine.

This slight hesitation can lead to a disastrous decision. Using a non-certified seal isn't just a minor risk; it can cause your high-value shipments to be impounded at customs, leading to catastrophic delays and financial penalties.

ISO 17712 certification is important for security seals because it's a "passport" for international trade. Its purpose is to create a universal language of physical security and a minimum baseline of trust in a global supply chain where participants are strangers.

For years, I've seen clients treat ISO 17712 as just another line item on a spec sheet. But this perspective misses the entire point. I learned the hard way after a client tried to save a few hundred dollars on non-certified seals, only to have their $250,000 shipment of electronics held at the Port of Long Beach for three weeks. The demurrage fees alone wiped out their entire profit margin. That's when I realized the truth: ISO 17712 isn't a quality certificate for a product. It's a universal passage agreement for your cargo. It's the one thing that allows a customs officer in Rotterdam to trust a seal that was applied in Shanghai by someone they will never meet.

What Specific Performances Does the ISO 17712 Certification Actually Test?

You know the certification is important, but what does it actually prove about the seal's physical strength?

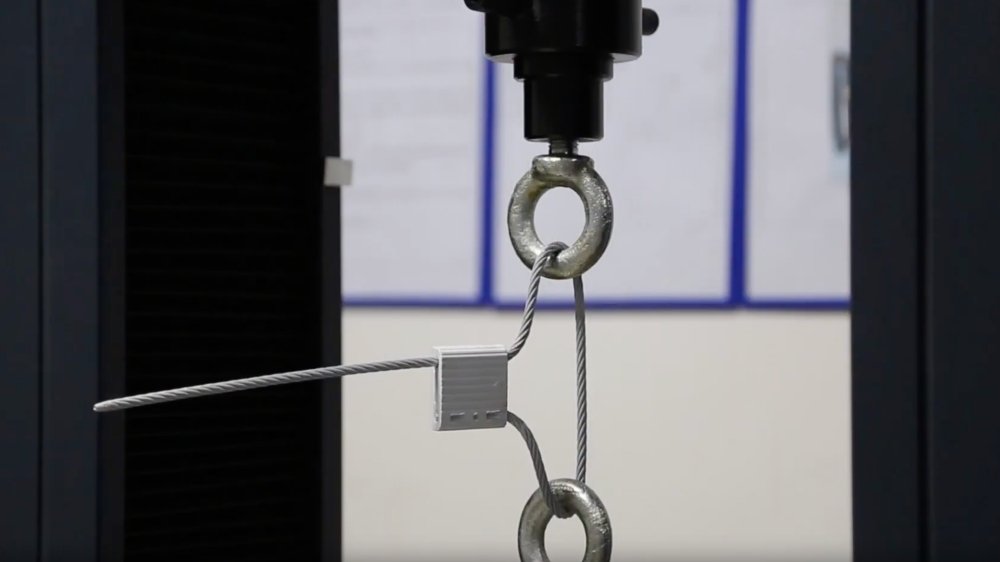

Passing the ISO 17712 test for a High-Security ("H") rating means the seal survived a barrage of brutal, standardized physical tests designed to simulate aggressive tampering.

A seal doesn't get an "H" rating easily. It must be sent to an accredited, independent laboratory and proven to withstand specific forces. These tests are the foundation of that "common language" of security.

| Test Type | What It Measures | What It Simulates in the Real World |

|---|---|---|

| Tensile Test | Pull Strength: The seal is pulled apart by a machine. It must withstand over 1,000 kg (2,205 lbs) of force. | An attempt to forcefully pry or pull a container's doors apart without cutting the seal. |

| Shear Test | Cutting Resistance: A blade device tries to slice through the seal's pin. It must withstand over 340 kg (750 lbs) of force. | An attack using large, powerful bolt cutters or shears. This ensures only specialized tools can defeat it. |

| Impact Test | Brute Force Hardness: The seal is subjected to a series of powerful strikes at various temperatures (hot and cold). | An attempt to smash the seal off its locking mechanism with a heavy object like a hammer or sledgehammer. |

These tests ensure that any compliant "H" seal provides a real, time-consuming barrier to intrusion.

How Could Lacking ISO 17712 Certification Impact Your Shipment's Customs Clearance?

You took a chance on a non-certified seal. What's the realistic worst-case scenario at the border?

The consequences are not a slap on the wrist. They are immediate, costly, and can cripple your delivery schedule and reputation.

When a customs agent sees a non-compliant seal on a container destined for a country with strict regulations (like the U.S. under C-TPAT), it triggers a predictable and painful chain of events.

The Inevitable Consequences

- Mandatory Inspection: Your container is immediately flagged and moved to a separate area for a full inspection. This is a non-negotiable delay.

- Costly Demurrage Fees: While your container is waiting to be inspected and then released, it's racking up demurrage or detention fees from the port and shipping line. These can range from $100 to $300 per day, sometimes more. A two-week delay can cost you thousands.

- Rejected Entry: In the absolute worst-case scenario, the shipment could be deemed too high-risk and denied entry into the country altogether, forcing you to pay for its return.

What Potential Business Risks Arise from Using Non-Certified Seals?

Beyond customs, are there other hidden risks to using a "cheaper" seal?

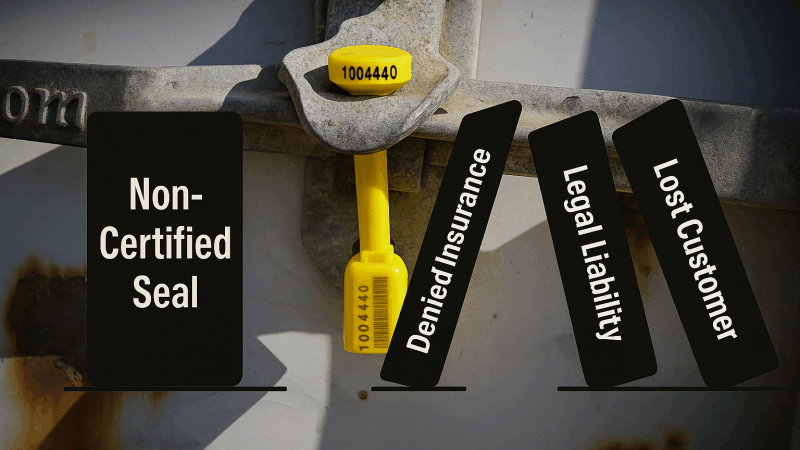

Yes. The customs headache is just the beginning. The business risks permeate your finances, legal standing, and customer relationships.

Saving a few dollars on a non-certified seal can expose your business to a cascade of failures.

Beyond the Border: A Cascade of Failures

- Insurance Claim Denial: If your cargo is stolen and you used a non-compliant seal, your insurance provider may argue you failed to take "due diligence" to secure the property. This could be grounds to deny your claim entirely.

- Legal Liability: Many shipping contracts and purchase orders explicitly require the use of ISO 17712 compliant seals. Failing to do so puts you in breach of contract.

- Customer Loss & Brand Damage: A single delayed or lost shipment can destroy the trust you've built with a client. The reputational damage from being known as an unreliable shipper is often the highest cost of all.

What Is the Relationship Between ISO 17712 and C-TPAT?

You ship to the United States and keep hearing about C-TPAT. How does it connect to ISO 17712?

The relationship is simple and absolute: ISO 17712 is the standard; C-TPAT is the program that requires the standard.

Think of it this way:

- ISO 17712 is the international "rulebook" that defines what a high-security seal is and how it must perform. It's a global benchmark.

- C-TPAT (Customs-Trade Partnership Against Terrorism) is a voluntary supply chain security program led by U.S. Customs and Border Protection (CBP). As a condition of membership, C-TPAT mandates that all loaded shipping containers bound for the USA must be secured with an ISO 17712 "H" class seal.

If you are a C-TPAT partner or ship to one, using a certified "H" class seal is not a choice; it's a fundamental requirement of the program.

How Can You Verify if a High-Security Seal is Genuinely ISO 17712 Certified?

A supplier claims their seals are certified. How can you be sure and avoid counterfeits?

This is a critical step. "Trust, but verify" is essential. A fraudulent certificate is just as dangerous as a non-certified seal.

I always instruct my clients to perform this simple, 3-step verification process before making a large purchase.

- Request the Certificate: Ask the manufacturer for a copy of their ISO 17712:2013 certificate. A legitimate supplier will provide this without hesitation.

- Check the Issuing Lab: Look at the name of the laboratory that issued the certificate. The lab itself must be accredited under ISO/IEC 17025 for testing seals. A quick search will confirm the lab's credentials.

- Confirm Clause 6 Compliance: The certificate must explicitly state that the manufacturer's processes are certified as compliant with Annex A of ISO 17712. This clause ensures the supplier has best practices in place to prevent tampering and counterfeiting within their OWN facility. A seal can't be trusted if the manufacturer's security is weak.

Conclusion

ISO 17712 certification is the essential passport for your goods in global trade. It's the common language of trust that keeps the supply chain moving. Viewing it as a strategic tool, not a quality sticker, is key to protecting your business from risk and ensuring smooth delivery.

Secure Your Global Shipments with ProtegoSeal

Don't let a non-compliant seal become the weakest link in your supply chain. The experts at ProtegoSeal provide only genuinely certified ISO 17712 High-Security Seals that act as your trusted passport for international trade. Contact us to secure your shipments and your peace of mind.