You're trying to choose a seal and see terms like "ISO 17712," "Indicative," and "High-Security." These technical labels can be confusing, making you unsure if you're choosing the right seal.

Making the wrong choice based on a misunderstanding of these terms can lead to serious consequences, including regulatory fines, customs delays, or a security breach that should have been preventable.

Security seals are classified based on their "anti-intrusion strategy," primarily defined by the ISO 17712 standard. This system doesn't rank a seal's quality; it defines its function—whether its job is to provide evidence of tampering or to create a robust physical barrier to delay an attack.

When I was first learning the ropes in this industry, I made a common mistake: I thought the ISO 17712 ratings were a quality score, like a 1-to-5-star review. It took years of analyzing failed seals and security breaches to understand the profound truth. These classifications are not a quality grade. They are a functional definition system based on a seal's "Anti-Intrusion Strategy." The system doesn't answer the question, "How good is this seal?" It answers a much more important one: "How does this seal defeat an intrusion attempt, and for how long will it delay the intruder?"

How Are Security Seals Graded Based on the ISO 17712 Standard?

You see "ISO 17712" on a spec sheet. Is this just another technical code you can ignore?

Absolutely not. This is the single most important global standard for security seals, and understanding it is critical for anyone involved in shipping and logistics.

ISO 17712 is the international standard that sets the requirements for mechanical security seals. But as I've said, it's best understood as a strategic framework. It classifies seals into three main categories based on their physical strength and, more importantly, their intended function in a security protocol.

| ISO 17712 Clause | Classification | Anti-Intrusion Strategy |

|---|---|---|

| Clause 4 | Indicative (I) | "Inform & Surrender": Designed to be easily broken by hand or with a simple tool. Its only job is to provide clear, immediate visual evidence that tampering has occurred. It offers no meaningful delay. |

| Clause 5 | Security (S) | "Resist & Show": Requires a more substantial tool to defeat. It offers a limited delay to an intruder while still being designed to show clear evidence of the attack. |

| Clause 6 | High-Security (H) | "Delay & Deter": Built to be extremely tough, requiring heavy-duty tools like bolt cutters to remove. Its primary mission is to significantly delay an intruder, increasing their risk of being caught. |

Viewing the classifications through this strategic lens changes everything. You're no longer just buying a piece of plastic or metal; you're deploying a specific anti-intrusion tactic.

How Are Different Material Types—Like Plastic, Metal, and Cable—Categorized?

You have a plastic seal and a steel bolt seal. How does their material affect how they're categorized?

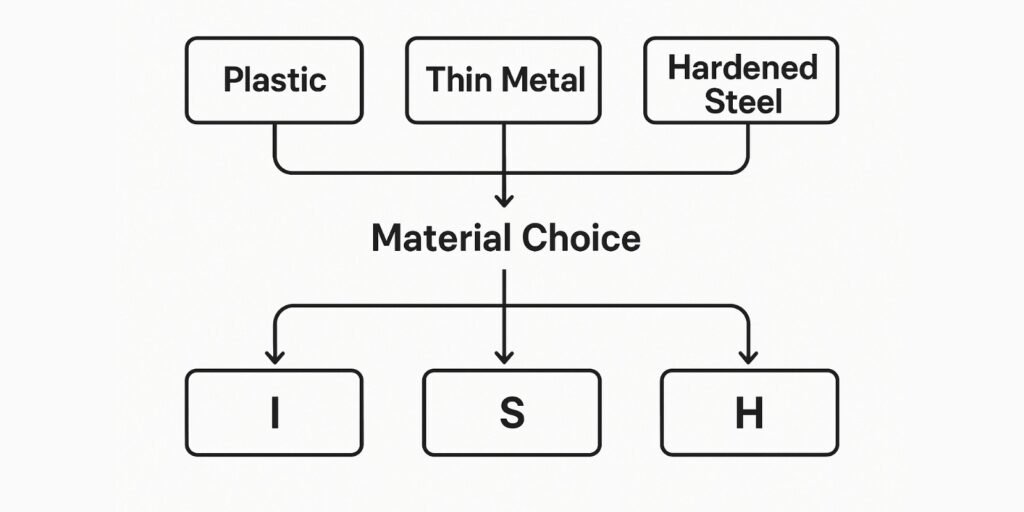

The material a seal is made from is the primary factor that determines its anti-intrusion strategy and, therefore, its classification. The choice of material is deliberate and functional.

In my experience inspecting countless seals, the link between material and function is undeniable. Each material is chosen to engineer a specific type of failure or resistance.

Plastic (Polypropylene & Nylon)

- Category: Almost exclusively Indicative (I).

- Strategy: "Inform & Surrender." Plastic is chosen for its low breaking strength. It's designed to snap, stretch, or permanently deform when attacked, providing an unambiguous visual signal. Its weakness is its greatest informational strength.

Metal (Tin-Plated Steel & Aluminum)

- Category: Can be Indicative (I) or Security (S).

- Strategy: "Resist & Show." Thin metal strip seals offer more durability than plastic in harsh environments but are still designed to bend and break, indicating an attack. Heavier metal bodies, like those on cable seals, contribute to a higher security rating.

Cable & Bolt (Hardened Steel)

- Category: Almost exclusively High-Security (H).

- Strategy: "Delay & Deter." Hardened steel pins and multi-strand steel cables are chosen for their immense tensile strength. Their job is to resist cutting and brute force for as long as possible, forcing thieves to use specialized, heavy equipment.

What Is the Correlation Between a Seal's Material and Its ISO Security Rating?

Can a plastic seal ever be "High-Security"? Can a steel seal be merely "Indicative"?

Generally, no. There is a direct and logical correlation between the physical properties of a material and its potential ISO security rating. You cannot achieve a high-security rating without high-strength materials.

To achieve a specific ISO 17712 rating, a seal must pass a series of rigorous physical tests that measure its resistance to tensile, shear, and impact forces. The material is the foundation of this performance.

- To be Indicative (I): The seal must be easy to break. This is why they are made of plastic. The material's properties ensure it fulfills the "Inform & Surrender" mission.

- To be Security (S): The seal needs to withstand more force but still show evidence. This is often achieved with stronger plastics or thinner metals.

- To be High-Security (H): The seal must withstand immense force. It must pass tests demonstrating it can resist over 1,000 kg of tensile pull. Only hardened steel components, like those in bolt and heavy-duty cable seals, can meet this demanding physical requirement and fulfill the "Delay & Deter" mission.

Therefore, a seal's material fundamentally dictates its potential ISO rating.

What Is an "Indicative Seal" and What Are Its Key Characteristics?

Someone tells you to use an "indicative seal" on a fire extinguisher. What does that actually mean?

An indicative seal is, quite simply, an informant. Its entire purpose is to serve as a visual indicator of use or access. It is not a lock.

As the name implies, an indicative seal provides indication of tampering. I always stress to my clients that they should never expect this type of seal to stop a thief. That is not its mission. Its key characteristics are all designed to support its "Inform & Surrender" strategy:

- Low Breaking Strength: Designed to be removed by hand or with minimal force. This ensures that any attempt to open the sealed item results in a broken seal.

- Clear Evidence of Tampering: When broken, it cannot be glued back together or reassembled. The evidence of tampering is permanent and obvious.

- Unique Identification: They are always marked with a unique serial number. This prevents a thief from simply removing the seal and replacing it with a new, identical one—a tactic known as replacement fraud.

- Low Cost: Their simple plastic construction makes them highly cost-effective for applications requiring thousands of single-use seals.

Why Must a "High-Security Seal" Meet Specific Material and Design Standards?

Why is there so much focus on the specific steel and dimensions of a high-security bolt seal?

Because its mission—"Delay & Deter"—is the most critical in the entire supply chain security ecosystem. Its design isn't arbitrary; it's a piece of anti-theft engineering.

A high-security seal is the last line of defense for high-value international shipments. For this reason, Clause 6 of ISO 17712 mandates not just performance but also specific design features to prevent sophisticated attacks.

- Material Mandates: The standard requires materials of significant strength, typically hardened steel, to resist force.

- Dimensional Requirements: For bolt seals, the standard specifies a minimum pin diameter (18mm) to ensure it can't be easily cut by standard-sized bolt cutters.

- Anti-Tamper Features: High-security seals must incorporate features that show evidence of tampering. For example, high-quality bolt seals include an "anti-spin" feature, where the pin and barrel lock together, preventing a thief from spinning the seal at high speed to friction-weld it back together after an attack.

- Permanent Markings: All markings must be laser-engraved, not printed, so they cannot be removed or altered.

These strict requirements ensure the seal can reliably perform its mission of creating a significant, time-consuming barrier for any potential attacker.

Conclusion

Security seal classification is a functional system based on a seal's anti-intrusion strategy. By understanding whether a seal's mission is to "inform," "resist," or "delay," you can move beyond a simple good/bad judgment and make a strategic choice that perfectly matches your security needs.

Deploy the Right Strategy with ProtegoSeal

Stop guessing about security classifications. At ProtegoSeal, we help you diagnose your needs and deploy the correct anti-intrusion strategy, from Indicative plastic seals to High-Security bolt seals. Contact us to engineer a smarter security solution.