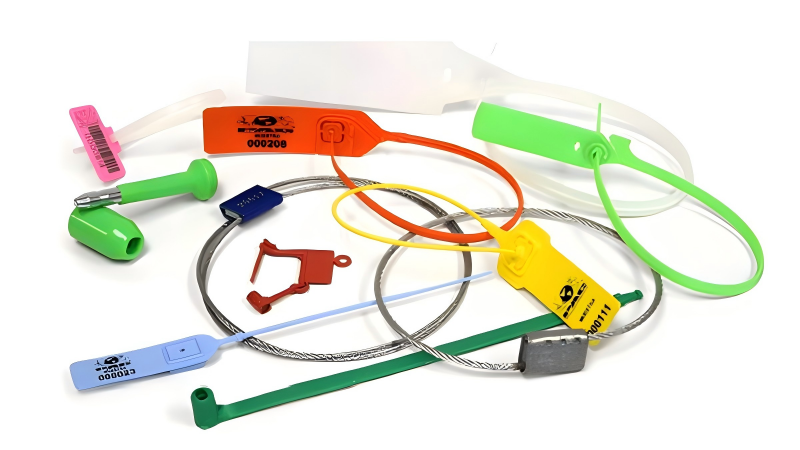

You're looking at a catalog of security seals—bolt seals, cable seals, plastic pull-tights—and they all seem so different. You feel overwhelmed, worried you'll pick one that's too weak or waste money on one that's overkill.

This uncertainty can lead to a critical mismatch, leaving your assets either under-protected or your budget unnecessarily strained. You risk choosing a seal that fails its fundamental security task.

Choosing the right seal means matching the tool to the "security mission." The six main types—bolt, cable, plastic, metal strip, padlock, and meter seals—are specialized instruments, not steps on a security ladder. The right choice is a diagnostic process, not a judgment of "good vs. bad."

When I first started in quality control, I saw the world of seals as a simple ladder from weak to strong. It took years of analyzing real-world applications to see the truth: this view is completely wrong. The six main types of security seals aren't a hierarchy; they are specialized tools designed for six fundamentally different "security missions." My job isn't to sell the "strongest" seal. It's to act as a diagnostician, helping clients precisely match the seal's mission to their specific security need. This diagnostic approach is the only way to achieve true, cost-effective security.

What Are the Six Core Types of Security Seals You Should Know?

You know you need a seal, but what are the actual categories and what is each one for?

Knowing these six distinct missions is the first step in your diagnostic process. Each one solves a very different security problem.

Let's break down the mission for each of the six core types of security seals. I've found that thinking about their purpose, rather than just their material, makes the choice much clearer for my clients. This framework moves the conversation from "what is it made of?" to "what job does it do?"

| Seal Type | Primary Security Mission | Common Materials |

|---|---|---|

| High Security Bolt Seals | Rigid Barrier & Deterrence: To physically delay an attack on standardized, high-value shipments like shipping containers. | Hardened Steel, Aluminum |

| High Security Cable Seals | Flexible Barrier & Versatility: To provide a high-strength barrier for irregular applications, like securing multiple latches or equipment with misaligned locking points. | Steel Cable, Aluminum Body |

| Plastic Seals | Tamper Evidence & Information: To provide immediate, clear, and undeniable visual evidence of any tampering attempt. | Polypropylene, Nylon |

| Metal Strip Seals | Durability in Harsh Conditions: To provide reliable tamper evidence on equipment that experiences high vibration and rough handling. | Tin-plated Steel |

| Padlock Seals | Quick Inspection & Auditing: To offer a familiar padlock form for applications needing easy, visual confirmation of a sealed state. | Polypropylene, Acetal |

| Meter Seals | Protecting Critical Data: To secure utility meters and other calibrated instruments from unauthorized adjustments or fraud. | Polycarbonate, Wire |

How Do You Match the Right Seal Type to Your Specific Application?

You understand the missions, but your facility has everything from truck doors to small cabinets. How do you apply this knowledge practically?

You continue the diagnostic process by examining the physical reality of what you're sealing. The application itself will tell you which tool to use.

After identifying the general mission, I guide my clients through a three-point physical check. This simple diagnosis almost always points to the perfect seal type.

1. The Locking Point Requirement

First, look at what you're sealing. A truck door has a large hasp designed for a thick steel bolt. A canvas bag's zipper has a tiny aperture that can only accept a thin plastic strap. A complex valve assembly with multiple, misaligned holes demands the flexible strength of a cable seal. The physical dimensions of the locking point often make the initial choice for you.

2. The Required Break Strength

Next, assess the value of the contents and the threat level. For a $200,000 shipment of electronics, you need a high-barrier seal that requires bolt or cable cutters to remove. This is a measure of intrusion resistance. For a tote of internal documents, you just need a seal that can't be opened by hand, ensuring an evidence trail. The required force to break the seal should match the risk.

3. The Environmental Conditions

Finally, consider the environment. A seal on a tanker traveling through a desert needs to withstand extreme heat and UV exposure. A metal strip seal on a railcar hopper needs to endure constant, high-frequency vibration without failing. Choose a material that is engineered for the environmental stresses it will face.

Does Your Shipment Legally Require a High Security Bolt or Cable Seal?

You're preparing a container for international shipping and someone mentions C-TPAT. Are you legally obligated to use a specific type of seal?

In many cases, yes. For international trade, failure to use a compliant high-security seal can result in costly delays, fines, and inspections at the border.

This is one area where the choice is not optional; it's a matter of regulatory compliance. The key standard you need to know is ISO 17712.

What is ISO 17712?

This is the international standard that establishes uniform procedures for the classification, acceptance, and withdrawal of mechanical freight container seals. It defines three classes of seal strength: "I" for Indicative, "S" for Security, and "H" for High Security.

What is C-TPAT?

The Customs-Trade Partnership Against Terrorism is a U.S. Customs and Border Protection (CBP) initiative. To be C-TPAT compliant, all loaded containers bound for the U.S. must be secured with an ISO 17712 "H" class high-security seal. Typically, only heavy-duty bolt seals and cable seals can achieve this classification.

Security vs. Cost: How to Decide Between Plastic and Metal Seals?

Your primary mission is tamper evidence, not a high-security barrier. Should you use a cheaper plastic seal or a more durable metal strip seal?

This is a common diagnostic challenge. The answer lies in balancing the need for clear evidence against the operational lifespan and environment of the asset being sealed.

When a high-security barrier isn't the mission, both plastic and metal strip seals serve as "indicative seals"—their job is to provide evidence. Here's how I advise clients to choose between them:

Choose Plastic When:

- Versatility is Key: You need to seal a wide variety of items with different locking point sizes (e.g., bags, carts, cages).

- Cost is a Major Factor: For high-volume, single-use applications, the lower per-unit cost of plastic seals provides significant savings.

- Color-Coding is Needed: Plastic seals are ideal for logistics systems that use color to denote routes, contents, or inspection dates.

Choose Metal Strip When:

- Durability is Paramount: You're sealing truck doors that will see a lot of vibration and road grime.

- Weather Resistance is Critical: The tin-plated steel offers superior resistance to long-term UV exposure and extreme temperatures.

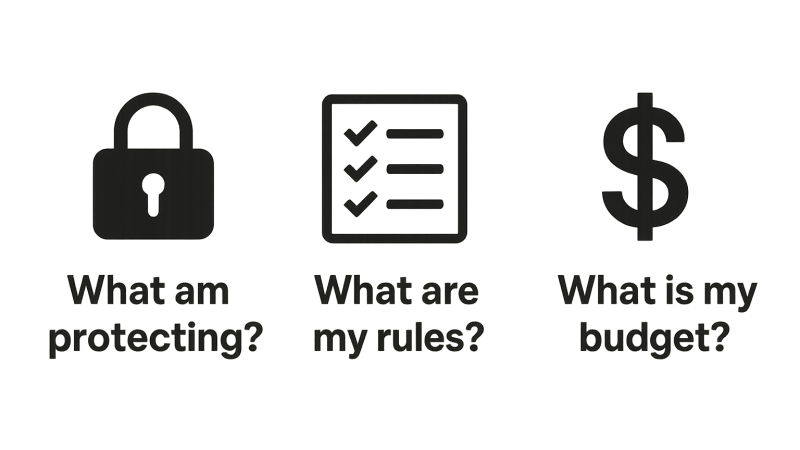

What Three Questions Should You Ask Before Choosing the Perfect Seal?

You feel confident in the types and missions. How can you boil this down to a final, simple decision-making process?

After all the analysis, it comes down to three final diagnostic questions. Answering these will point you to the right seal every time.

Before you place your next order, run through this final mental checklist. This is the same process I use on the phone with new clients to quickly narrow down the options.

What is my primary "security mission"?

Am I trying to stop a determined criminal with a rigid barrier (Bolt Seal) or a flexible one (Cable Seal)? Or do I need to know if anyone has tried to gain access (Evidence Mission -> Plastic Seal)? Start with the mission.What are my operational and regulatory requirements?

Does the locking point require a thin, flexible strap, or a strong, flexible cable? Am I shipping to the USA and therefore need a C-TPAT compliant, ISO 17712 "H" seal? Let the physical and legal constraints guide you.What is the most cost-effective solution that accomplishes the mission?

Don't over-secure. If an inexpensive plastic seal perfectly fulfills your evidence mission, using a more expensive high-security seal is a waste of money. True security is about effectiveness, not expense.

Conclusion

Choosing the right seal is a diagnostic process of matching your specific security mission to the right tool. Understand the six core missions, assess your application, and you will achieve effective, cost-efficient security every time.

A Diagnosis for Your Security Needs with ProtegoSeal

Stop guessing and start diagnosing. The expert team at ProtegoSeal can help you analyze your security missions and prescribe the perfect seal for the job—from bolt seals to cable seals and every mission in between. Contact us for a professional consultation.