You need to secure a high-value shipment, so you reach for the strongest thing you can find: a heavy-duty metal bolt seal. You equate its strength and weight with better security.

But what if a skilled thief manages to subtly defeat it and reattach it? The seal might still look intact upon arrival, but your cargo is gone. Your "strongest" seal failed to tell you it had been compromised.

No. Metal seals are stronger barriers, but plastic seals are ofAn image comparing a heavy-duty metal bolt seal and a simple plastic pull-tight seal, with question marks and checkmarks over them indicating different types of security.ten superior for tamper evidence. "Security" is not just about resisting an attack; it's about providing clear, undeniable information that an attack happened. A plastic seal's designed "weakness" makes it a better informant.

In my early days in this industry, I was like most people: I thought stronger was always better. But my perspective was completely changed by years of analyzing tampered seals. I realized that a metal seal’s security comes from its "high resistance threshold," but this is precisely its greatest weakness when it comes to tamper evidence. For tamper evidence, security isn't about how much force a seal can resist, but how sensitively and clearly it can "record and report" an attack. From this viewpoint, a plastic seal’s "fragility" is actually its greatest informational advantage, because it makes any attempt at tampering impossible to hide.

Redefining 'Security': Barrier Strength vs. Informational Integrity?

You think "security" is a single concept: stopping a bad guy. But in the world of seals, there are two distinct security philosophies.

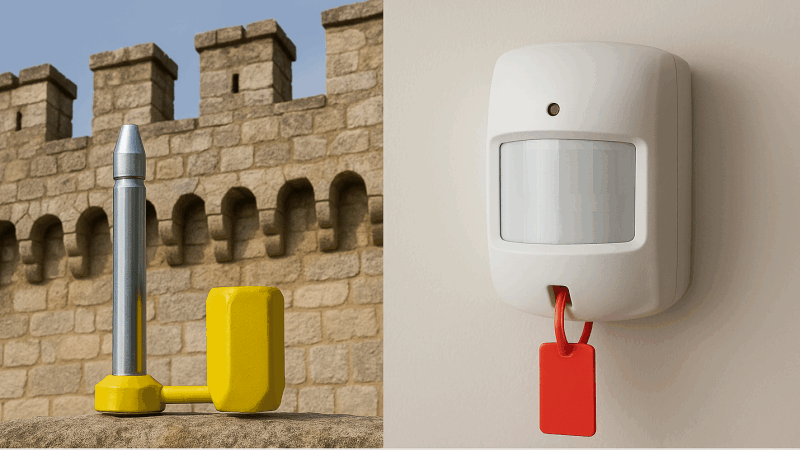

Understanding this difference is the key to choosing the right tool. You must decide if your priority is to build a wall or to install a highly sensitive alarm system. A metal seal is a wall; a plastic seal is an alarm.

This is the most critical concept I teach my clients. It changes how they view their entire security program.

| Security Model | Barrier Strength (Metal Seals) | Informational Integrity (Plastic Seals) |

|---|---|---|

| Primary Goal | Physically delay or stop an intruder. | Provide undeniable proof of an intrusion attempt. |

| How it Works | High physical resistance; requires heavy tools to defeat. | Low physical resistance; designed to break or deform permanently. |

| Success is... | An intact seal after an attempted break-in. | A clearly broken seal after an attempted break-in. |

| Analogy | A bank vault door. | A chemical test strip that changes color. |

One model focuses on resistance, the other on evidence. Confusing the two is a common and costly mistake. Barrier strength is about protecting the asset itself, while informational integrity is about protecting the integrity of the chain of custody.

The Use Case for High-Barrier Security: When Metal Seals Are the Non-Negotiable Choice?

So, if plastic seals are better "informants," is there ever a reason to use a big metal seal?

Absolutely. When you are trying to physically delay a determined attacker or meet strict regulatory requirements, a high-barrier metal seal is the only option.

In these scenarios, the goal is to make a break-in so difficult and time-consuming that the thief gives up or is caught. I always insist on a high-security metal seal in these situations:

- High-Value Cargo: When you're shipping items like pharmaceuticals, electronics, or spirits, the seal must act as a serious physical deterrent. The goal is to force the thief to use noisy, heavy-duty tools like bolt cutters, increasing their risk of being caught.

- International & Customs Compliance: Programs like C-TPAT (Customs-Trade Partnership Against Terrorism) require shipments to be secured with seals that meet the ISO 17712 "H" (High-Security) classification. Only metal bolt seals and some heavy-duty cable seals can meet this standard.

- Unsupervised Dwell Time: If a container will be left unattended in a high-risk area for a long period, a barrier seal provides a much stronger line of defense against an opportunistic attack.

In these cases, the "high resistance threshold" is precisely what you need.

Is 'Stronger' Always 'Better'? The Hidden Costs and Risks of Over-Securing

You've used a bolt seal on a routine, low-risk shipment "just to be safe." What could possibly go wrong?

Using a seal that is too strong for the application—a practice known as "over-securing"—introduces its own set of risks and inefficiencies.

I once had a client who was using bolt seals on everything. Th2025-11-25 17:41:52 Tuesdayeir receiving department was complaining constantly. We investigated and found several problems:

- Operational Inefficiency: Removing a bolt seal requires a specific, powerful tool and takes significantly more time than snipping a plastic seal. For a warehouse receiving hundreds of items a day, this added up to major labor costs.

- Failed Information: We found a few seals that had been cleverly glued or spun. The break-in was successful, but the bolt seal was too "strong" to break, so it failed to report the subtle attack. A plastic seal would have snapped, providing clear evidence.

- Safety Hazards: Cutting a hardened steel bolt can create flying metal fragments, posing a real eye-injury risk to employees. It introduced an unnecessary workplace hazard.

Over-securing is not just wasteful; it can be less secure from an informational standpoint and even dangerous.

The Role of Plastic Seals in a Barrier-Focused Context: Suitability and Smart Application

If a metal seal is the primary barrier, is there any role for a plastic seal?

Yes, a very important one. A plastic seal can serve as an incredibly effective "first-layer" alarm, even when a metal seal is also present. This is called layered security.

For a truly robust security posture, layering different types of seals can be highly effective. A plastic seal is the perfect instrument for what is known in security as compelling a choice. It forces an attacker to make a decision and reveals their intent.

Imagine a trailer door with a plastic seal on the latch. An opportunistic thief might try to quickly pry it open. The plastic seal snaps instantly. They may not have breached the main lock, but the broken seal provides immediate evidence that an attempt was made when the driver does their walk-around inspection. This allows security teams to increase vigilance or reroute the asset. The plastic seal acts as a sensitive, early-warning system, while the metal seal remains the heavy-duty barrier.

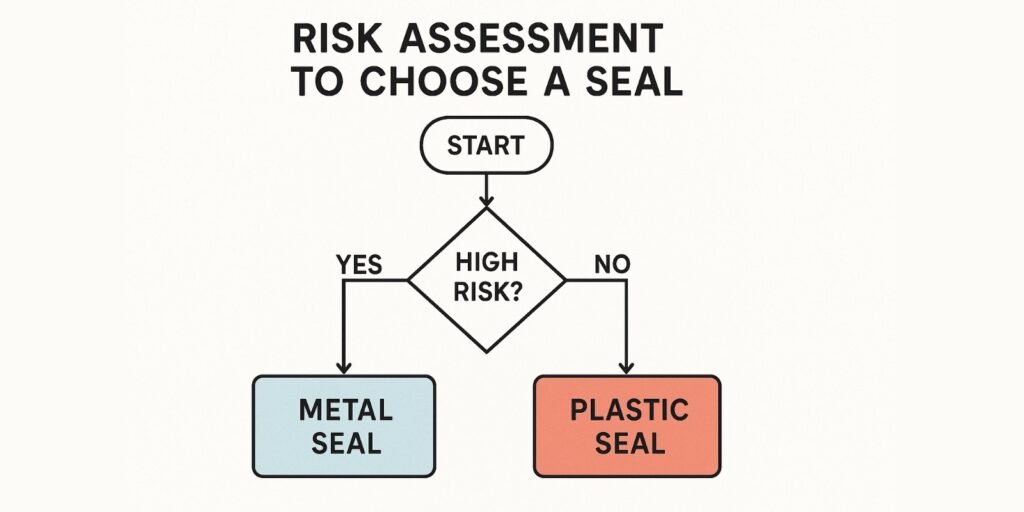

A Risk-Based Framework: How to Match the Right Seal to Your Shipment's Security Level

How do you decide between a wall and an alarm? You need to assess the risk.

You should never make a seal choice based on habit. A proper risk assessment will lead you to the most effective and efficient solution every time.

Here is the simple framework I use with my clients:

- Assess Your Cargo Value: Is it a box of paper or a $100,000 pallet of electronics? Higher value demands a stronger barrier.

- Assess Your Threat Environment: Are you shipping within a secure, closed-loop system or across borders through high-risk areas? Higher threat demands a stronger barrier.

- Assess Your Primary Goal: Do you need to stop an attack (delaying entry), or do you need to know an attack happened (gathering evidence)? If knowing is more important, you need a better informant.

| Risk Profile | Primary Security Goal | Recommended Seal Type |

|---|---|---|

| High Value / High Threat | Barrier Strength (Delay Intruder) | Metal Seal (Bolt or Cable) |

| Low Value / High Volume | Informational Integrity (Evidence) | Plastic Seal (Pull-tight) |

| Mixed / Layered Need | Early Warning & Barrier | Plastic Seal + Metal Seal |

Conclusion

A metal seal's strength makes it the superior barrier, but a plastic seal's designed fragility often makes it the superior choice for tamper evidence. The most secure choice is not always the strongest; it's the one that provides the right information for your specific risk level.

Build a Smarter Security Strategy with ProtegoSeal

Stop choosing between strength and information. At ProtegoSeal, we help you implement a risk-based framework to select the perfect seal—metal or plastic—for every shipment. Contact us to design a security strategy that's not just strong, but smart.