You're buying plastic seals and see the Polypropylene (PP) option is often cheaper than HDPE. You instinctively think "cheaper means less secure," and opt for the "stronger" HDPE to be safe.

This common assumption can be a mistake. You might be overspending on a seal that is actually less efficient for your needs, or worse, one that creates ambiguity where you need absolute clarity, leading to disputes and delays.

You should choose a Polypropylene (PP) security seal over HDPE when your top priorities are unmistakable tamper evidence, high-volume operational efficiency, and complex color-coding, especially for securing indoor or light-duty assets. PP excels by providing clear, "single-break" evidence at a lower operational cost.

I always challenge my clients when they dismiss PP seals as simply a "budget" choice. The truth is, when your security needs are more about the clarity of evidence and the efficiency of your operations, PP often becomes the superior choice over HDPE. Choosing PP isn't a compromise on security; it's an active optimization for "security efficiency." You don't choose it because it's cheaper; you choose it because, in the right context, it delivers more appropriate and clearer security for your investment.

When You Need Unmistakable, "Single-Break" Tamper Evidence?

Your inspector finds a bent HDPE seal. Was it pried at by a thief, or just crushed between two pallets?

This ambiguity is a security manager's nightmare. It wastes time and can lead to false alarms or disputes. This is where PP's unique properties make it the smarter choice.

Early in my quality control career, I spent countless hours examining seals from the field. It became obvious that while HDPE is flexible and strong, that very flexibility can be a weakness in providing evidence. PP, on the other hand, is much stiffer. It doesn't like to bend; it prefers to break. This is its superpower.

The Power of Binary Evidence

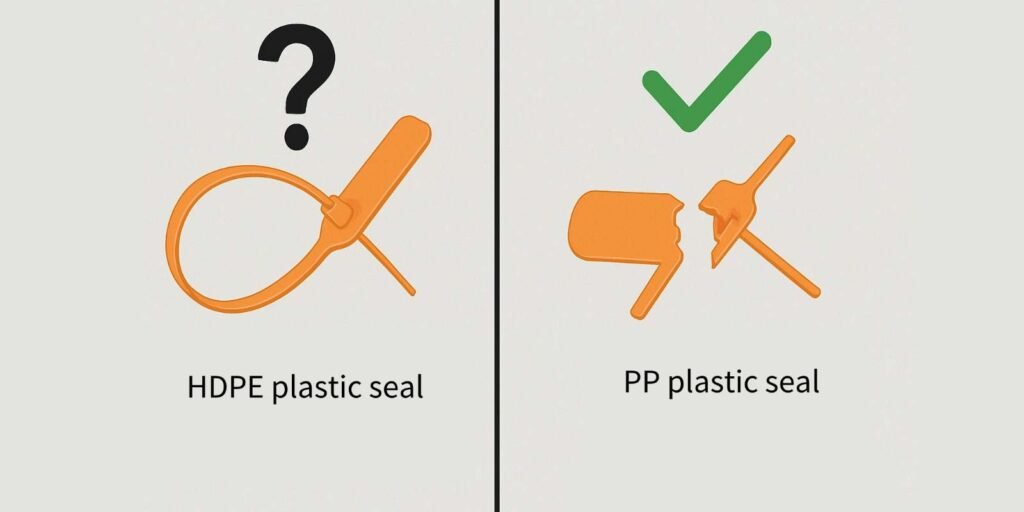

Unlike HDPE, which can stretch and show "stress whitening," PP provides what I call "binary evidence." It's either perfectly intact, or it is broken. There is no confusing middle ground. When a PP seal is subjected to a significant pulling force beyond its design, it doesn't elongate—it snaps cleanly.

This material property nearly eliminates the debate over whether a seal was tampered with or accidentally damaged.

- Tampering Attempt: A thief must apply enough force to break the seal, leaving a clear, snapped link. It's impossible to glue back together without obvious signs.

- Inspection: Your team doesn't need to interpret subtle stress marks. The inspection is a simple "yes" or "no": Is it broken? This drastically speeds up the auditing process and reduces the chance of human error.

When You Need to Deploy Seals in High Volume, Cost-Effectively?

You're sealing thousands of roll cages or tote boxes every single day. Every second and every cent counts.

In high-volume logistics operations, like retail distribution or postal services, efficiency is king. Here, PP's combination of lower material cost and rapid, foolproof inspection makes it the undisputed champion.

This is where the concept of "security efficiency" truly shines. We're not just looking at the price per seal; we're looking at the total cost of the security operation. I once worked with a massive retailer who was using more expensive, flexible seals on their distribution totes. Their inspectors were spending precious seconds on each tote trying to decide if a bent seal was a problem. We switched them to a simple PP pull-tight seal.

The results were immediate:

- Lower Unit Cost: The PP seals were less expensive, resulting in significant savings across millions of units per year.

- Faster Application & Inspection: The simple pull-and-snap application was quick. More importantly, the "broken or not" inspection took less than a second per tote.

- Reduced Training Burden: New employees could be trained on the simple inspection protocol in minutes.

The "cost-benefit analysis" wasn't just about the seal's price; it was about the saved labor hours and the increased throughput of their entire distribution center.

When Securing Indoor or Light-Duty Assets like Carts and Cabinets?

You need to seal a hospital medicine cabinet, an in-flight catering cart, or a first-aid kit. Do you really need a high-strength HDPE seal for this?

Absolutely not. Using an overly-strong seal for a light-duty application is not only overkill, but it can also be impractical. PP seals are perfectly designed for these scenarios where the primary need is tamper evidence, not brute-force barrier strength.

The goal here isn't to prevent someone with a pair of bolt cutters from getting in; it's to provide an immediate visual indication that the contents have been accessed. This is a crucial element of inventory control and process integrity.

- Low Breaking Strength by Design: Many light-duty PP seals are designed to be removed by hand with a firm tug or a simple cutting tool. This is a feature, not a bug. It ensures authorized personnel can access the contents quickly in an emergency (e.g., a medical kit) without needing heavy tools.

- Perfect for Access Control: For things like fire extinguishers, secure file cabinets, or utility meters, the seal's job is to serve as a visual tag. A broken seal instantly tells a manager or inspector that the item has been used or accessed and needs to be checked or replenished. A heavy-duty seal would be an unnecessary and cumbersome obstacle.

When Your Logistics Rely on a Complex Color-Coding System?

You manage a complex logistics chain where goods need to be routed to different departments or sorted by date, and errors are costly.

This is a scenario where a seal must do more than just secure; it must communicate. PP is an excellent material for vibrant and consistent color production, making it the ideal choice for implementing a robust visual management system.

While HDPE can also be colored, PP tends to offer a wider, more vivid, and more consistent color palette. For a large logistics operation, this is a powerful organizational tool. I've designed systems with clients where the color of the seal provides instant information:

- Red: High-priority or rush shipment.

- Blue: Route to Department A.

- Green: Inspected and cleared quality control.

- Yellow: To be audited before dispatch.

This visual shorthand reduces errors, speeds up sorting, and allows anyone on the floor to understand the status or destination of an asset with a single glance. In this context, the color of the seal becomes as important as its serial number, and PP delivers these colors reliably.

The Key Exception: When Extreme Strength or Environments Mandate HDPE?

So, is PP always the "smarter" choice? No. There are clear situations where the superior toughness of HDPE is non-negotiable.

When your primary risk is not subtle tampering but brute-force attack, or when the seal will face extreme environmental stress, HDPE is the only responsible choice.

Recognizing the limits of PP is just as important as understanding its strengths. I would never recommend a standard PP seal in these situations:

- Extreme Cold: As discussed before, PP can become brittle in freezing temperatures. For refrigerated containers or shipments to severely cold climates, HDPE's superior cold-weather performance is essential to prevent seal failure.

- High-Strength Barrier Needs: For applications where the seal is a primary component of a physical barrier, like securing a tote of high-value electronics, an HDPE seal with a stronger metal locking mechanism provides a more formidable defense against a brute-force attack. The goal here is to increase the time and effort required for a thief to break in.

Choosing the right seal is about matching the tool to the threat level and operational reality.

Conclusion

Choosing a PP seal is a strategic decision for efficiency. It provides clearer, faster tamper evidence for high-volume and light-duty roles where operational speed and clarity matter most. It is not a compromise; it's an optimization.

Optimize Your Security with ProtegoSeal

Stop guessing if PP or HDPE is right for you. At ProtegoSeal, we help you analyze your specific operational needs to determine which material provides the most efficient and effective security. Contact us to implement a smarter, more cost-effective sealing strategy today.