A critical valve is found in the wrong position. Was it an accident? Malice? Who is accountable? Without a clear physical record, you are left investigating a mystery instead of preventing a disaster.

A car seal is a single-use locking device that secures a valve in one position. It provides an immediate, visual, and undeniable indication of tampering or unauthorized access, transforming your safety procedures from abstract rules into a concrete physical evidence chain.

Over my career, I've seen clients struggle with complex safety procedures that exist only on paper. The car seal changes that. It's an engineered component, often plastic or metal, that integrates a "single-use lock" with a "unique identity." Its sole purpose is to turn an abstract safety rule into a tangible, undeniable piece of physical evidence. You might wonder how it "works." A car seal's mechanism is based on a simple, irreversible locking structure. Its real "job" is to provide an absolutely clear signal, without any need for interpretation, through its two states: "intact" or "broken." This moves safety from a matter of trust to a matter of verifiable fact.

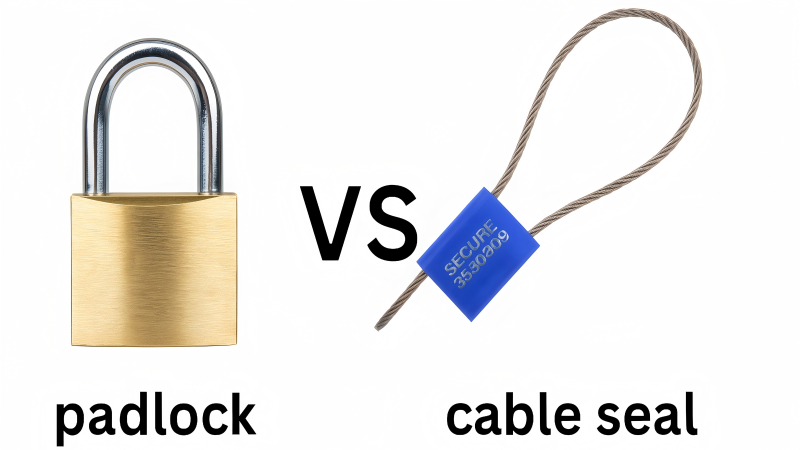

What Exactly is a Car Seal, and How Does It Differ from Traditional Padlocks and Tags?

You're using a reusable padlock and a flimsy paper tag to secure your valves. The key gets lost, duplicated, or the tag tears off, leaving the valve's status ambiguous and creating a major safety risk.

This is a critical point of failure. A car seal is fundamentally different because it combines a lock and a tag into one single-use device, eliminating the weaknesses of traditional, multi-part systems.

Having worked in quality control and now in sales, I've seen the confusion that traditional systems cause during safety audits. A padlock is reusable, which sounds good but is actually a security flaw in this context. A key can be shared or copied, breaking the chain of accountability. A tag is just information; it provides no physical security. A car seal solves both problems by design.

Car Seal vs. Padlock & Tag System

| Feature | Padlock & Tag System | Car Seal | Why It Matters |

|---|---|---|---|

| Usage | Reusable lock, disposable tag | Single-use device | A car seal cannot be re-applied once broken, creating a permanent record of access. |

| Accountability | Tied to key control, which can be weak. | Tied to a unique serial number. | The seal's number is logged. If it's broken and replaced, the number change is an immediate red flag. |

| Integration | Two separate components (lock + tag). | Lock and identification are one integrated unit. | There's no risk of a tag falling off or a lock being used without proper identification. It's a single point of truth. |

A car seal is designed to be destroyed upon removal, making it the perfect tool for proving a valve has remained in its intended state since the moment it was secured.

How Does a Car Seal's Unique Locking Mechanism Prevent Accidental Valve Operation?

An operator, working quickly, opens a valve they thought was safe to operate. They didn't see the small warning tag, leading to a product cross-contamination incident that costs thousands of dollars to fix.

This kind of human error is common. A car seal prevents these accidents by introducing a deliberate, physical barrier. It forces a "moment of pause," turning an easy, accidental action into a conscious, intentional one.

The core principle here is simple but incredibly effective. You cannot "accidentally" remove a car seal. Turning a valve handle is a simple, often reflexive motion. But cutting a high-strength cable or snapping a plastic seal requires a tool and a specific decision. This is a powerful concept in industrial safety known as a "forcing function."

I always explain it to my clients this way: a hanging tag is a suggestion, but a car seal is a physical question. To remove it, an operator must stop and ask:

- "Am I authorized to change this valve's state?"

- "Do I have the correct work order?"

- "Am I about to break a logged security device?"

This deliberate step is often all that's needed to prevent a costly mistake. It engages the operator's mind in a way a simple tag never could. It's not just a seal; it's an active part of your Process Safety Management (PSM) system, providing a real-world barrier against human error.

In Which Critical Industrial Scenarios is Using a Car Seal a "Must-Do" for Safety?

You run a complex facility. Are there specific situations where just a tag isn't enough, where a car seal is the absolute minimum requirement for safety and compliance?

Yes, absolutely. In any high-consequence scenario where an incorrect valve position could lead to a safety incident, environmental damage, or significant financial loss, car seals are a "must-do."

From my experience working with clients in high-stakes industries, car seals are non-negotiable in several key areas. These aren't just best practices; they are often tied to strict regulatory requirements and are essential for protecting people and assets.

Here are some prime examples where car sealing is mission-critical:

| Industrial Scenario | Why a Car Seal is Essential | Potential Consequence of Failure |

|---|---|---|

| Long-Term Isolation | Securing valves that must remain open or closed for extended periods (e.g., seasonal lines, decommissioned pipes). | Accidental activation of a dormant line, leading to spills or pressure build-up. |

| Critical Process Safety Valves | Sealing pressure relief valves or emergency shutdown valves to ensure they are not tampered with and are ready for an emergency. | Failure of a critical safety system during an incident, leading to a catastrophic event. |

| Change-Over Manifolds | During product change-overs, sealing off lines to prevent cross-contamination between different chemicals or food products. | Huge financial loss from contaminated product batches, costly line cleaning, and potential recalls. |

| Fire Suppression Systems | Ensuring the main water or foam supply valves for fire systems remain open at all times (Car Seal Open - CSO). | A fire suppression system that fails to activate because a valve was inadvertently closed. |

In these situations, the car seal isn't just a lock. It's proof of compliance and a vital component of your facility's safety case.

How to Implement a "Car Seal Program" to Comply with Safety Standards (like LOTO)?

You want to improve safety, but you need a structured process. How do you go from buying car seals to having a fully functional, auditable program that integrates with standards like LOTO?

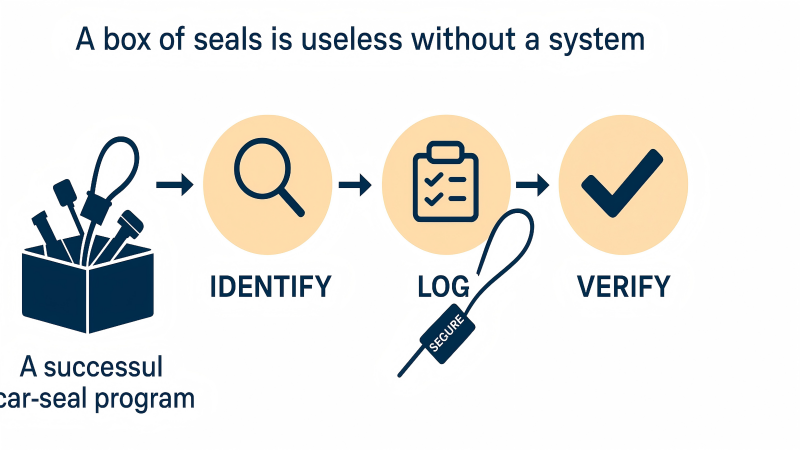

A box of seals is useless without a system. A successful car seal program is a simple, repeatable workflow that documents the "what, where, when, and who" for every sealed valve, making your process auditable and effective.

The best programs I've helped implement are built on the principles of Lockout/Tagout (LOTO). The car seal becomes the physical "lock" and "tag" in one, providing visual proof that the LOTO procedure is active.

A Simple 4-Step Car Seal Program

- IDENTIFY the State: The maintenance or operations team determines the required state of the valve (e.g., Car Seal Open or Car Seal Closed).

- LOG the Action: In a logbook or digital system, a supervisor records the date, time, valve identifier, the required state, and the unique serial number of the car seal being applied. The name of the authorized person applying the seal is also recorded.

- SEAL the Valve: The authorized person physically attaches the car seal, securing the valve handle to the valve body or surrounding pipework to prevent it from being operated.

- VERIFY the Removal: When the valve's state needs to be changed, an authorized person checks the log, verifies the work order, and records the seal removal. The broken seal is often kept with the paperwork as physical proof until the job is closed out.

This creates a closed-loop system of accountability. An auditor can pick any seal in your plant, check its number against the log, and see its entire history. This is how you demonstrate true control.

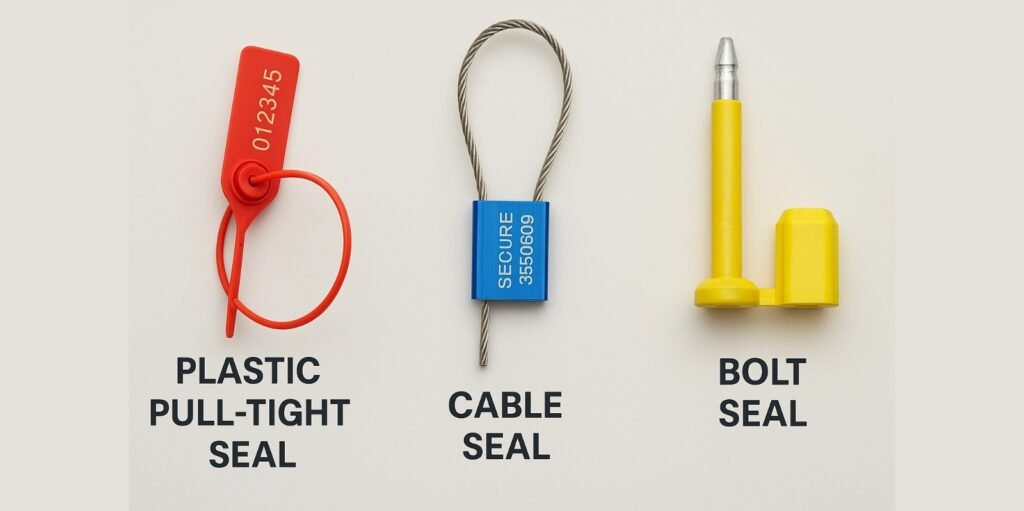

Choosing the Right Car Seal: The Difference and Application of Plastic, Cable, and Bolt Seals.

You're ready to buy, but you see three main types: plastic pull-tight seals, cable seals, and bolt seals. Which one is right for which application?

Choosing the wrong type of seal can undermine your entire program. The choice depends on the security level required, the valve's design, and the operating environment.

This is a common question, and getting it right is crucial. Each seal type is a tool designed for a specific job. Using a light-duty plastic seal where a heavy-duty cable seal is needed is a recipe for failure.

Here’s a simple breakdown based on a decade of helping clients make this choice:

| Seal Type | Lock Mechanism | Breaking Strength | Best Application |

|---|---|---|---|

| Plastic Pull-Tight Seal | Plastic strap with a one-way locking chamber. Like a zip tie. | Low | Securing small valves, cabinet doors, or as a quick "tamper-evident" tag. Best for low-security needs where evidence of opening is all that's required. |

| Cable Seal | A steel aircraft cable threaded through a locking body. | Medium to High | The most versatile car seal. The flexible cable can secure almost any valve type, including gate valves and lever-operated valves. The go-to choice for most industrial LOTO applications. |

| Bolt Seal | A steel pin that locks into a separate steel bushing with a "click." | Very High | Securing things that require significant barrier strength, like container doors or large valve enclosures. Generally overkill for standard valve handle lockout, but useful for securing a valve's larger gearbox or actuator. |

For 90% of valve sealing applications within a plant, the cable seal is the workhorse. It offers the best balance of security, flexibility, and clear tamper evidence.

Conclusion

A car seal is not a commodity; it's a strategic tool. It transforms your safety procedures from paper theories into a physical reality, providing a clear, undeniable signal that protects your people, products, and profits.

Implement a Flawless Safety Program with ProtegoSeal

Ready to move from abstract rules to concrete safety? At ProtegoSeal, we are experts in designing and supplying car seal solutions for critical industries. We help you choose the right seal and build an auditable program. Contact us to create your physical evidence chain today.