Staring at a container door full of bars and handles can be overwhelming. One mistake in placing the seal could cost you thousands in lost cargo or delays. The secret? You need to learn to ignore 99% of what you see.

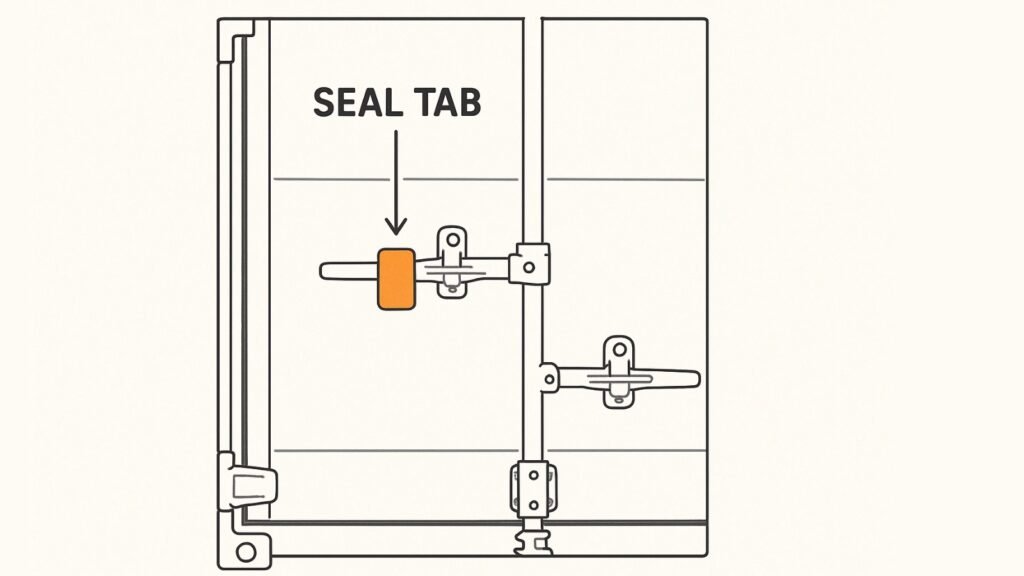

The single correct position for a container seal is on the right-hand door. Your entire job is to find the small seal tab (hasp) on the keeper of the outer locking bar and apply a bolt seal. This single point, this critical 1%, secures the entire container.

In my experience, nearly every sealing error stems from the same cognitive bias: operators get distracted by the complex web of handles and locking bars. My core principle is simple: Ignore the 99%. Your attention should be focused entirely on a single, correct sealing point. Finding and locking this point with a high-security bolt seal is the entire mission. Anything else is a distraction and a potential error. This guide will train your eyes to find that critical 1%.

What is the Anatomy of a Container Door? Identifying the Correct Latching Points

You're looking at a wall of steel. All those bars and handles seem important, don't they?

Sealing the wrong part is the number one mistake, born from distraction. You must train your eyes to differentiate between the operational parts and the single, designated security point.

The key isn't to learn every part, but to learn which parts to ignore. Think of it as a "Target vs. Distraction" exercise. In my early days in QC, this mental shift was a breakthrough. Here’s a breakdown of what to focus on and what to disregard:

| Part Name | Classification | Reason |

|---|---|---|

| Door Handles | Distraction | These are just levers to provide torque for turning the locking bars. They are not security points. |

| Left Door | Distraction | This door is physically blocked by the right door. Sealing it is pointless. |

| Locking Bars | Distraction | These are part of the mechanism, but they are not the locking point. Don't seal around them. |

| Seal Tab (Hasp) | The 1% Target | This is the only component engineered specifically to accept the pin of a high-security bolt seal. |

Your mission is to find the seal tab on the right-hand door. It is the only part that matters.

The Golden Rule: The Single Correct Position for a Container Seal?

Is there truly only one right place, an in all that metal?

Yes. There is one "golden point." The entire system is designed for a bolt seal to be placed through the seal tab on the keeper of the right-hand door's outer locking bar. Following this rule is not optional; it is fundamental to container security.

This isn't an arbitrary rule; it's based on the mechanics of the door and recognized by global security programs like C-TPAT. When the right door closes, it physically blocks the left. The seal tab is a fixed-size hole, perfectly matched to a bolt seal's rigid pin to create an immovable lock. It's the designated end-point of the door's security sequence. A professional doesn't scan the whole door; their eyes go directly to this point. Any other action—like using a cable seal on an undamaged door—is an unnecessary deviation.

What Are Common Container Seal Placement Mistakes to Avoid?

You think the container is locked, but you've been distracted. What do these common errors look like?

These mistakes almost always happen when an operator loses focus on the critical 1% and starts interacting with the other 99% of the door's hardware.

These are the most frequent, and most costly, errors I see in the field. They are all symptoms of a distracted operator.

Mistake #1: Focusing on the Left Door

- The Error: The operator places a seal on the left door, thinking "a sealed door is a sealed door."

- Why it's Wrong: The right door closes over the left. A seal on the left door is completely useless once the right door is open. It’s a classic case of failing to see the sequence.

Mistake #2: Focusing on the Handles

- The Error: The operator uses a cable seal to tie the handle to the locking bar.

- Why it's Wrong: The handle is just a lever. This seal does nothing to prevent the locking bar itself from being lifted out of its bottom keeper bracket, allowing the door to be pried open.

Mistake #3: Focusing on "More is Better"

- The Error: The operator uses multiple seals or a long cable seal to bind both doors together.

- Why it's Wrong: This demonstrates a fundamental lack of understanding. It wastes seals, adds complexity, and raises immediate red flags for customs officials, who are trained to spot anything out of the ordinary.

Beyond Placement: The 3-Step Process for Verifying Your Container Seal?

You've found the 1% and placed the bolt seal correctly. Are you finished?

No. The final part of a professional's job is verification. You must confirm the seal is truly locked and document it. This is the simple but non-negotiable VVTT check: View, Verify, Tug, and Twist.

I cannot overstate this. I have personally investigated cases where a seal simply fell off mid-voyage because the operator didn't do this 10-second check. It creates a documentation nightmare and suspicion of tampering.

- V - View & Verify: Both shipper and driver look at the seal. They confirm the serial number on the seal matches the number on the Bill of Lading. This creates accountability.

- T - Tug: Grab the head and barrel of the bolt seal and give it a firm tug. It must not come apart. If it does, it was not locked correctly.

- T - Twist: For any high-security bolt seal with an anti-spin feature, try to rotate the pin and barrel against each other. If they do not spin freely, the locking mechanism is properly engaged.

Finally, take a clear photo of the locked seal. This is your proof of a job done with precision.

Exception Handling: Placing a Seal on a Damaged or Non-Standard Container?

What if the 1%—the seal tab—is broken or missing?

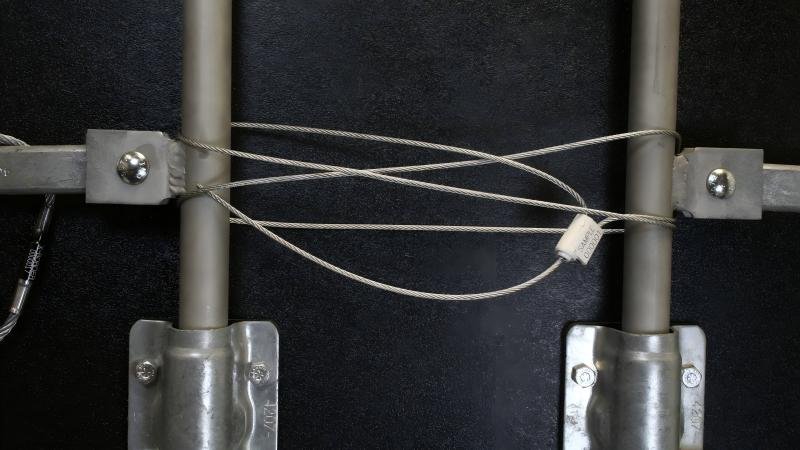

This is the only time you should deviate from the standard procedure. If the designated point for a bolt seal is unusable, you must switch to a high-security cable seal to solve the problem.

Your first and best choice is always to reject a damaged container. It's a liability. But if you must use it, you adapt while maintaining the core principle: immobilize the right-hand door's locking mechanism.

- Assess the Situation: The standard locking point for a bolt seal does not exist or is compromised.

- Adapt Your Tool: Use the flexibility of a high-security cable seal. Loop it through the keeper cam and tightly around the vertical locking bar. Cinch it down hard. You are creating an alternative, secure closure.

- Document Everything: This is not optional. Take multiple, clear photos of the damage and your cable seal application. Note the issue and the new seal number on all shipping documents, and immediately notify the receiver with the photos. Full transparency prevents problems down the line.

Conclusion

Placing a container seal is an exercise in focus. Ignore the 99% of distracting hardware. Find the critical 1%—the seal tab on the right-hand door—and secure it with a bolt seal. Master this, and you've mastered container security.

Develop Your Focus with an Expert Partner

Distractions lead to costly errors in cargo security. At ProtegoSeal, we provide more than just compliant seals; we deliver the expert knowledge to help your team focus on what matters. Need to train your operators to find the critical 1%? Contact us for a professional security consultation.