You need tamper-evident seals, but you're faced with two distinct options: destructible vinyl and VOID labels. Choosing the wrong one can mean a failed security protocol—a seal that damages a valuable asset or, conversely, one that can be subtly defeated.

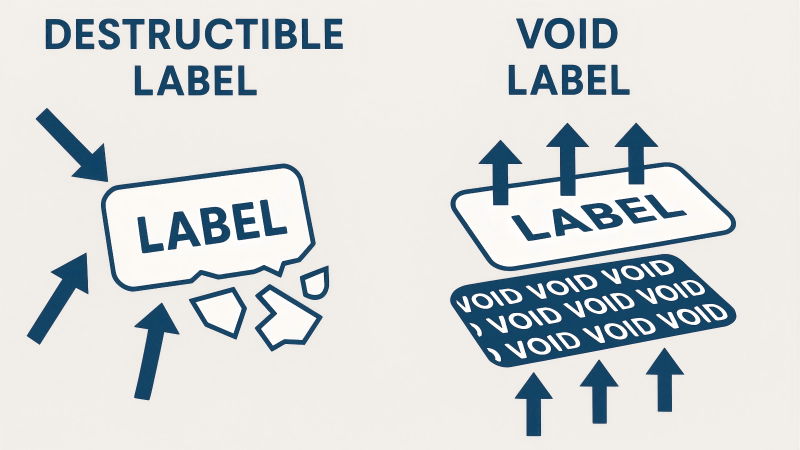

This choice boils down to two different security philosophies. Destructible vinyl is about "physical destruction," leaving a chaotic, impossible-to-repair scene. VOID labels are about "informational warning," leaving a clear, undeniable message that tampering occurred. Understanding this difference is key to your decision.

Clients often ask me which one is "better," but that's the wrong question. As a former QC inspector who has tested both to their limits, I can tell you the right question is, "Which is the correct tool for my specific job?" These two label types represent entirely different approaches to tamper evidence. One is a sledgehammer; the other is a sniper rifle. Both are effective, but you wouldn't use them interchangeably. Let's dissect their technical differences so you can choose with precision.

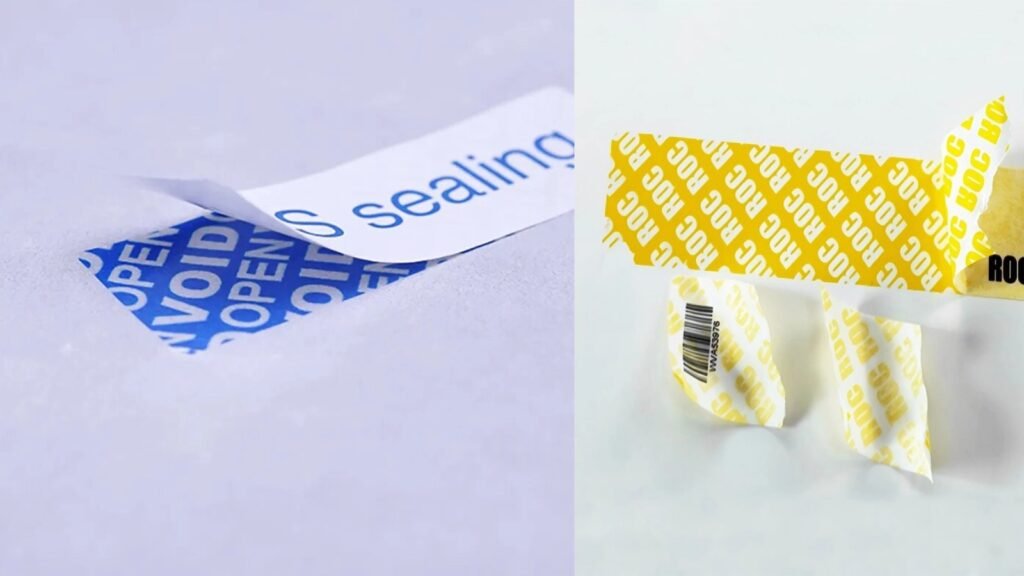

Tamper-Evident Mechanism: Physical Fragmentation vs. Delamination?

You know both labels show tampering, but you see one shatters and the other leaves a word. How do these different mechanisms actually work?

A destructible label works by fragmentation; its internal structure is so weak it shatters. A VOID label works by delamination; its engineered layers cleanly separate to reveal a hidden message, leaving the label and the message intact but apart.

This is the core of their design philosophies.

- Destructible Vinyl (Physical Destruction): Its power comes from a carefully engineered imbalance. The adhesive bond to the surface is made to be far stronger than the label’s own internal cohesive strength. When peeled, the glue holds firm, and the only thing that can give way is the brittle vinyl itself. It is designed to self-destruct.

- VOID Label (Informational Warning): This is a more complex structure. Imagine a sandwich with a special, patterned release layer in the middle. The bond between the top holographic/polyester layer and this release layer is weaker than the bond of the adhesive to the product surface. When peeled, the label splits perfectly along this pre-designed pattern, transferring a part of the label (the "VOID" message) onto the surface. The goal isn't destruction, but controlled separation.

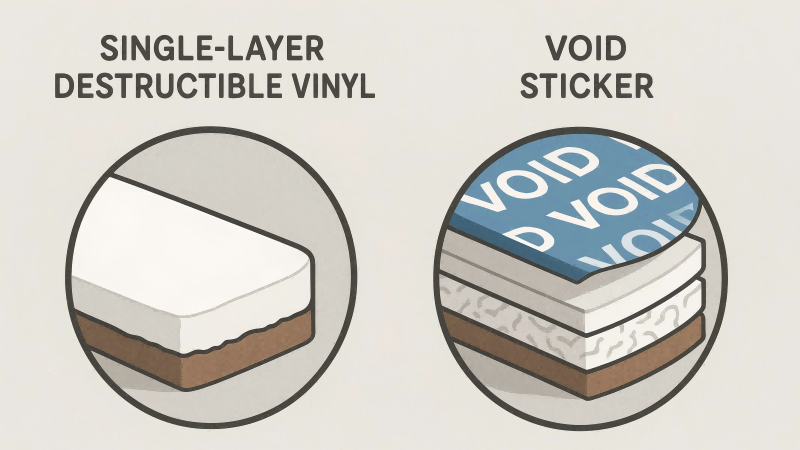

Material Composition: Brittle Vinyl vs. Multi-Layer Polyester Film?

You're choosing a label and need to know how it will hold up. Are the materials the same, just with different glues?

No, their base materials are fundamentally different. Destructible labels are made from a single layer of specially treated, highly brittle vinyl (PVC). VOID labels use a durable, multi-layer structure, typically based on flexible polyester (PET) film.

This difference in material composition directly impacts their real-world performance. As someone who has to consider a client's operating environment, this is critical.

- Brittle Vinyl: Think of it like an eggshell. It's rigid and not very flexible, which can make it challenging to apply on highly curved or uneven surfaces. It's also more susceptible to environmental factors; for instance, it can become even more brittle in extreme cold.

- Multi-Layer Polyester (PET): PET is known for its durability, flexibility, and stability across a wide range of temperatures. It's resistant to moisture and many solvents. This material is chosen for VOID labels precisely because the top film needs to remain stable and strong during the delamination process. You can't achieve that clean separation with a material that wants to shatter.

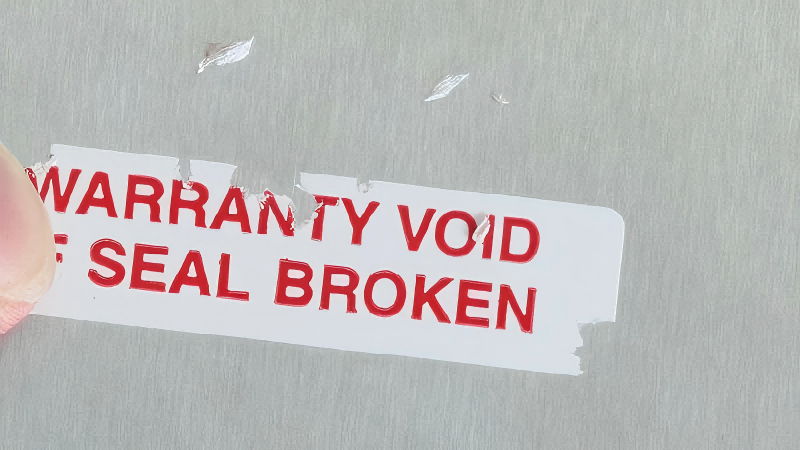

The Visual Evidence: Fragmented Residue vs. A Clean Text Message?

So, tampering has occurred. What a person sees as evidence is dramatically different between the two types. What does this mean for your verification process?

A destructible label leaves a messy, chaotic residue of tiny chips and fragments. A VOID label leaves a clean, legible, and

unambiguous text-based message like "VOID," "OPENED," or a custom pattern.

This visual difference gets back to my core point: "physical destruction" vs. "informational warning."

- The Destructible "Crime Scene": The shattered pieces are irrefutable proof that an attempt was made. It is visually arresting and signals obvious, aggressive tampering. However, the exact "message" can be messy and requires a person to interpret the damage. The cleanup is also a significant factor; removing the residue often requires scraping or solvents, which may damage the underlying product.

- The VOID "Information Alert": The evidence is a clean, clear signal. There is no ambiguity. The surface shows the word "VOID," and anyone, even from a distance, can understand what happened. This is ideal for logistics or secure access points where a quick, clear visual check is needed. The residue is often easier to clean than destructible vinyl, which is a key consideration for reusable assets.

Ideal Application Surfaces: From Flat to Curved, Porous to Smooth?

You have a specific product to seal. Will both labels stick to it and perform correctly?

No. Their material and adhesive properties make them suitable for different surfaces. Destructible vinyl excels on textured, porous, or powder-coated surfaces. VOID labels perform best on smooth, non-porous surfaces like glass, glossy plastics, and polished metal.

I always start a client consultation with the question, "What are you sticking it to?"

- Destructible Vinyl's Advantage: Its aggressive adhesive and the brittle nature of the face stock mean it can conform and bite into slightly irregular surfaces. It's the top choice for sealing paperboard packaging, powder-coated electronics casings, and anything where a smooth surface isn't guaranteed.

- VOID Label's Strength: For the clean delamination to work, the adhesive needs a consistent, high-energy surface to bond to. Smooth, clean surfaces are perfect. On a very porous surface like raw cardboard, the adhesive might not get a strong enough initial bond, potentially allowing the label to be removed without triggering the VOID effect properly. They are the go-to for sealing smartphone screens, laboratory equipment, and secure access doors.

The Decision Framework: When to Choose Destructible vs. VOID Labels?

You have all the technical data. Now, how do you make the final call for your project?

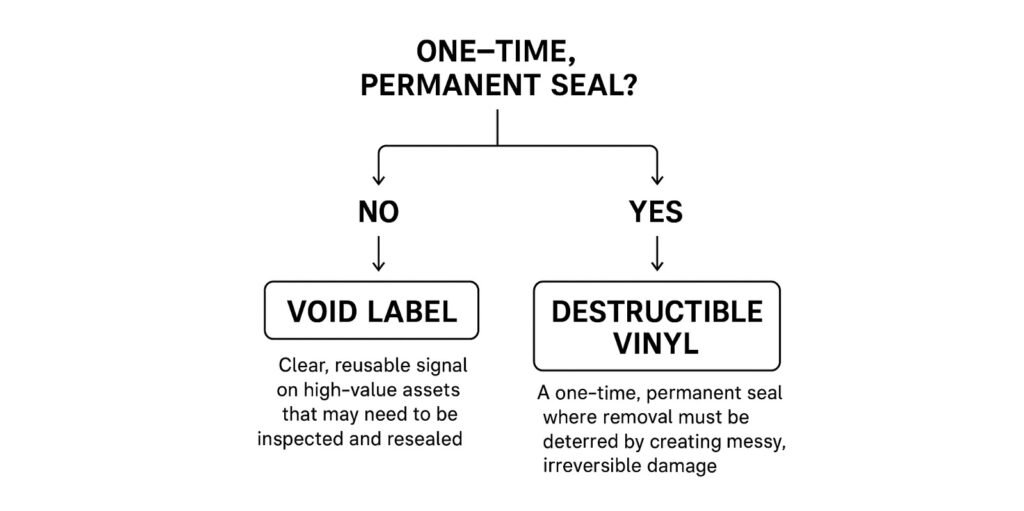

Choose destructible vinyl when your goal is a one-time, permanent seal where removal must be deterred by creating messy, irreversible damage. Choose VOID labels when you need a clear, reusable signal on high-value assets that may need to be inspected and resealed.

Let’s put it all into a simple decision-making table. I use this framework with my clients every day.

| Ask Yourself This Question: | If You Answer "YES," Choose: | If You Answer "NO," Choose: |

|---|---|---|

| Is the sealed item disposable or one-time-use? | Destructible Vinyl. Its messy residue is not an issue on an item that will be discarded. | VOID Label. The asset might be reused, so a cleaner, removable residue is preferable. |

| Is the primary goal to prevent any attempt at removal? | Destructible Vinyl. The prospect of creating a destructive mess is a powerful psychological deterrent. | VOID Label. The goal is less about deterrence and more about creating a clear record that access occurred. |

| Does the surface have a texture, powder coat, or is it porous? | Destructible Vinyl. It's more forgiving and effective on these challenging, low-energy surfaces. | VOID Label. It requires a smooth, high-energy surface for its mechanism to function reliably. |

| Do you need a quick, unambiguous visual check in a process? | VOID Label. A clear "OPENED" message is faster to verify in a logistics chain than inspecting for small shatters. | Destructible Vinyl. Close inspection is needed, which is fine for warranty returns or forensic analysis. |

Conclusion

The choice between destructible and VOID labels is a strategic one based on your specific security objective, the nature of your asset, and its surface. One provides physical destruction; the other offers an undeniable informational alert.

Choose Your Security Philosophy with an Expert

Navigating these technical details is what we do best. At ProtegoSeal, we help you select the precise tool for your security needs, ensuring your chosen solution performs flawlessly. Contact us to discuss your application and get samples of both technologies to test for yourself.