You need a way to seal an asset, but a standard label can be peeled off with a little heat and patience, leaving you with no proof of tampering. This opens the door to warranty fraud, unauthorized access, and asset swapping.

Destructible vinyl labels provide definitive tamper evidence by shattering into tiny pieces upon any removal attempt. This is achieved by engineering the label's internal strength to be far weaker than its powerful adhesive bond, ensuring it self-destructs when peeled.

In my work, I've moved beyond the simple "eggshell sticker" analogy. I define these labels as a "physical security trap." Their power comes from a precise application of material science. We deliberately create a huge difference between the adhesive's "stickiness" and the vinyl's own internal strength. This design choice means any attempt to tamper with the label triggers its self-destruction, creating an unrecoverable crime scene on the spot. It is the most direct physical deterrent. Let's explore how this technology works and where it fits in your security strategy.

What Is a Destructible Vinyl Label and Why Does It Shatter?

You see a label that looks sturdy, but you need to know if it has been tampered with. How can you be certain?

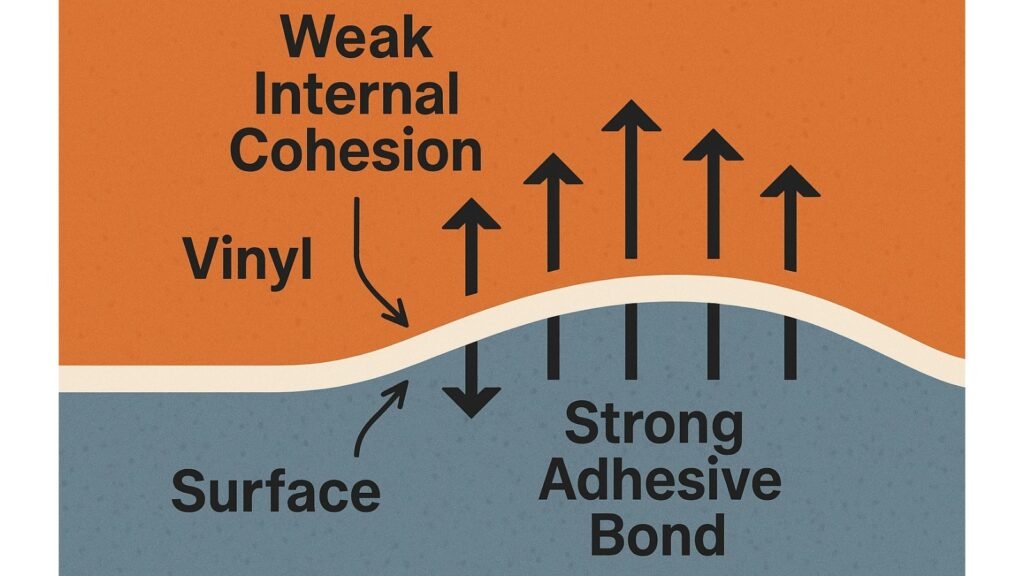

A destructible vinyl label shatters because it is engineered for "structural failure." Its own internal cohesive force is intentionally designed to be much weaker than the adhesive force of its backing glue. When you pull, the powerful glue holds fast, forcing the brittle vinyl to break apart.

This is where my experience as a QC inspector became fundamental to my understanding. It’s not about the material simply being "fragile." It’s about a calculated imbalance of forces. Think of it like this: the glue creates a bond with the product surface that is like cement. The vinyl material itself, however, is like a sheet of dried mud. If you try to pull the dried mud sheet off the cement, the cement bond won't break; the mud sheet itself will crumble. That is exactly what happens here. This isn't a defect; it's the intended, engineered result.

The Physics of a Security Trap

Let's break down the two competing forces at play:

| Force Type | Description | In a Destructible Label... |

|---|---|---|

| Adhesive Force | The strength of the bond between the label's glue and the product surface. | Extremely High. Designed to grip aggressively. |

| Cohesive Force | The internal strength holding the vinyl material itself together. | Extremely Low. Intentionally brittle and fragile. |

When someone tries to peel the label, the High Adhesive Force wins, forcing the Low Cohesive Force to fail. The label shatters as a direct result of this engineered imbalance.

How Does Fragmentation Provide Irrefutable Proof of Tampering?

A tamperer has tried to remove a label and failed. But how does the resulting mess provide undeniable proof for warranty claims or investigations?

The fragmentation creates a unique, chaotic pattern that is impossible to reassemble. The act of tampering itself produces permanent, visible evidence that cannot be hidden, repaired, or disputed, effectively turning the product itself into a witness.

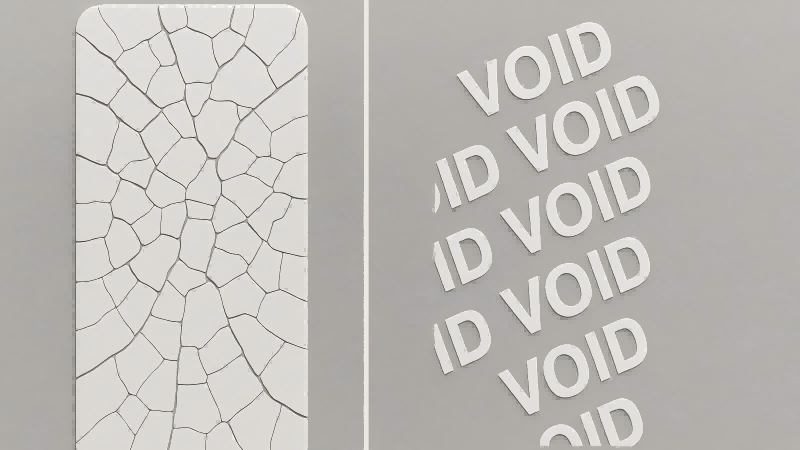

When a standard label is removed, a skilled person might be able to reapply it with minimal signs of entry. But a destructible label creates a scene of destruction. The tiny, chipped pieces cannot be pieced back together like a puzzle. There will be fragments left on the surface and a jagged, incomplete label in the tamperer's hand. Any attempt to place the ruined label back over the residue just makes the tampering more obvious. This is crucial for asset tracking and warranty management. If a sealed electronic device is returned with a shattered label, there is no ambiguity. The warranty is void. It provides a clear, binary "yes/no" answer to the question, "Was this opened?"

Destructible vs. VOID: Which Tamper-Evident Technology Should You Choose?

You know you need tamper evidence, but you've seen both "VOID" and "destructible" labels. Which one is right for your specific application?

Choose destructible vinyl for a powerful visual deterrent on uneven or porous surfaces where you need to prevent any removal. Choose VOID labels for a cleaner, non-destructive indication of tampering on high-value, reusable assets or smooth surfaces.

Having specced both solutions for hundreds of clients, the decision comes down to the asset's lifecycle and surface material. Destructible labels are like a dye pack for money—they offer a one-time, aggressive, and messy defense. They are perfect for sealing a disposable box or a single-use warranty seal. However, cleaning the shattered residue can be difficult. A VOID label, on the other hand, is a more "polite" security feature. It leaves a clear, legible message but typically doesn't damage the surface. This makes it ideal for reusable containers, aircraft doors, or server racks where the asset must be cleanly put back into service after inspection.

Your Quick Decision Guide

| Feature | Destructible Vinyl Labels | VOID Labels |

|---|---|---|

| Tampering Result | Shatters into small pieces; messy. | Leaves a clean, pre-defined word (e.g., "VOID"). |

| Best For Surfaces | Textured, porous, or uneven (e.g., powder-coated metal, cardboard). | Smooth, non-porous (e.g., glass, glossy plastic, polished metal). |

| Residue Cleanup | Difficult. Scraping is often required. | Easier. Often removable with specific solvents. |

| Primary Use Case | One-time warranty seals, calibration, asset ID on non-reusable items. | Reusable containers, access panels, high-value electronics. |

| Visual Deterrent | Very high. Looks difficult and messy to defeat. | High. Looks professional and technical. |

What Are the Ideal Applications for Destructible Vinyl Labels?

You understand the technology. Now, where does it actually make the most sense to apply these labels in a real-world business environment?

Destructible vinyl is ideal for any application where the primary goal is to prove an item has been opened, accessed, or altered. This includes warranty seals, calibration seals, and permanent asset identification on items that are not meant to be serviced.

In my experience, these labels solve very specific business problems. Here are the top use cases I've implemented:

- Warranty Seals: Placed over the seams or screw holes of electronics. If a customer opens the device to try a DIY repair (and breaks it), the shattered label proves the warranty is void. This has saved my clients thousands in fraudulent claims.

- Calibration Seals: Used on scientific or industrial equipment after it has been calibrated. A broken seal instantly indicates that the instrument's settings may have been tampered with and it needs recalibration. This is critical for ISO compliance.

- Asset & Property ID: For permanent identification of office equipment, tools, or IT assets. The label's tendency to shatter makes it incredibly difficult for a thief to remove the tag and claim the asset as their own.

- Pharmaceutical & Retail: Sealing non-prescription medicine bottles or high-value retail packages to assure the end consumer they are receiving a factory-sealed, untampered product.

Looking Ahead to 2025: What's Next in Destructible Label Technology?

This technology is effective, but you're wondering how it's evolving. Is it just about making things more brittle?

The future of destructible labels lies in combining the physical fragmentation with smart technology. Expect to see labels integrated with unique QR codes for digital verification and new material formulations that offer enhanced security features.

The innovation isn't just in the material science anymore; it's in the data layer. My role has evolved from just selling a physical product to providing a complete security solution. Looking towards 2025, we are actively developing and sourcing the next generation of these labels. We're seeing advancements in:

- Hybrid Destructible/VOID Materials: New formulations that both shatter and leave a specific word pattern, offering two layers of evidence.

- Embedded QR/NFC: Every label will have a unique, serialized digital identity. A scan can reveal the product’s history, and the system can flag a product as "tampered" the moment a seal is reported broken, providing real-time supply chain intelligence.

- Covert Features: Integration of invisible UV inks or microtext within the destructible material itself, adding a layer of forensic evidence that can only be seen with special tools, making it harder for counterfeiters to replicate even the look of an authentic label.

Conclusion

Destructible vinyl labels are a powerful security tool, operating on an engineered principle of "structural failure." They provide absolute, irreversible proof of tampering, making them an essential asset for warranty control and security.

Secure Your Assets with Engineered Certainty

Understanding the science is key to trust. At ProtegoSeal, we master the material science behind our products. We can help you choose the right solution, from advanced destructible vinyl to VOID labels, to create your own "physical security trap." Contact us to discuss your application and get a sample.